High-efficiency wear-resistant sludge pump

A kind of mud pump, high-efficiency technology, applied in the direction of pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve the problems of irreparable, heavy maintenance workload, sealing damage, etc., to achieve Prolong service life, save maintenance, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

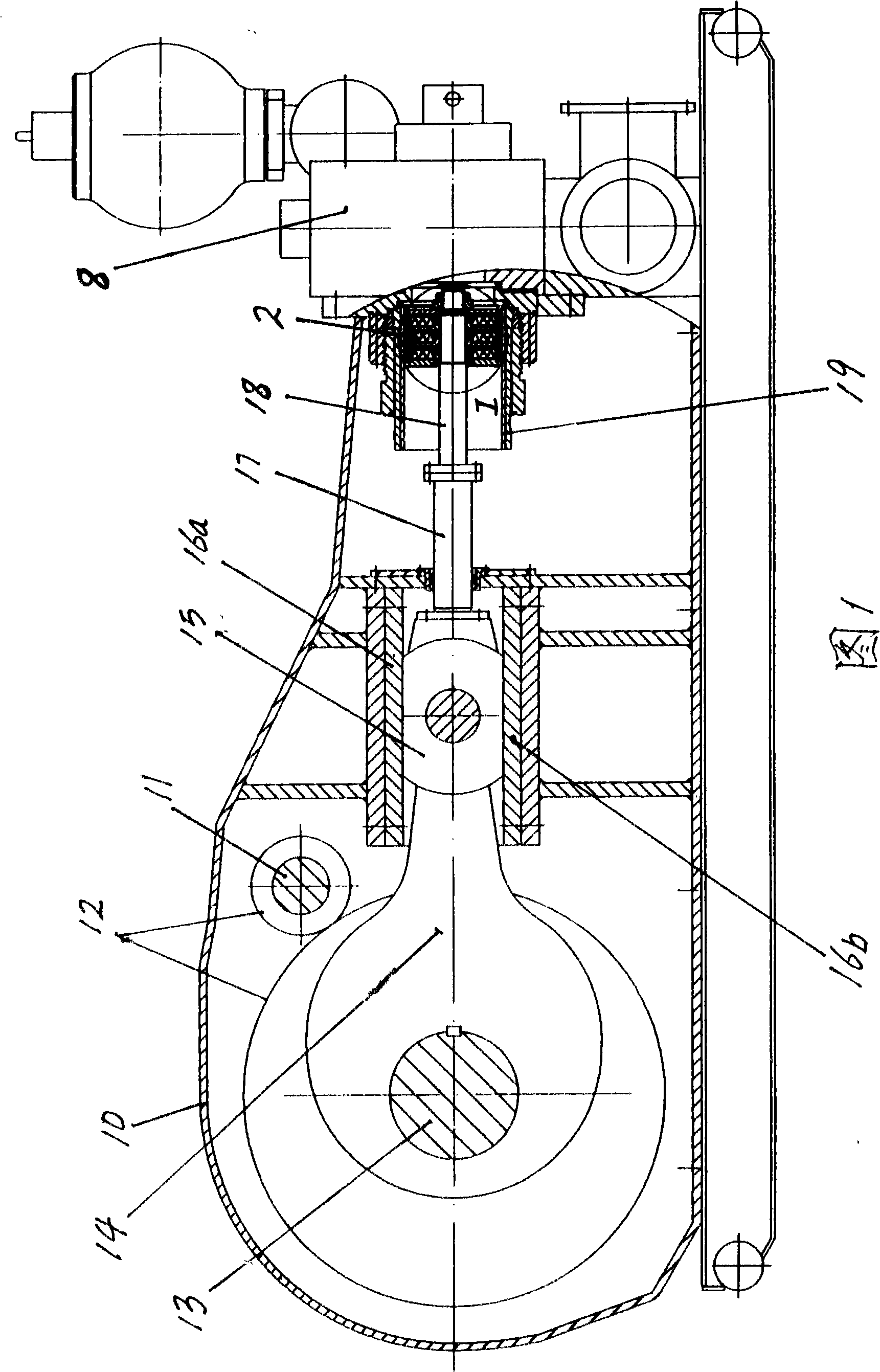

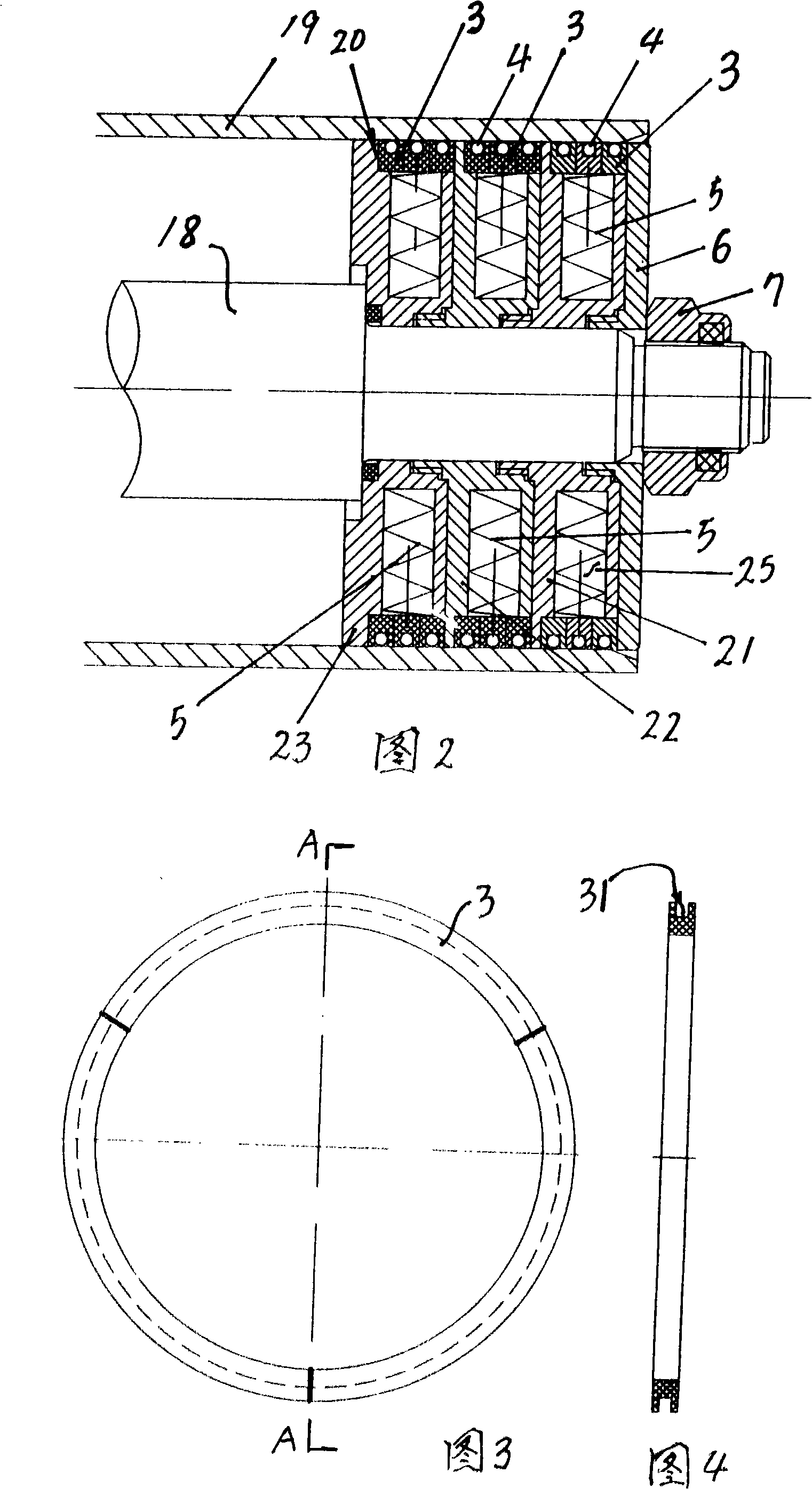

[0009] The present invention comprises organic casing 10, transmission shaft 11, transmission gear 12, crankshaft 13, connecting rod 14, slider 15, upper and lower guide plates 16a, 16b, transmission rod 17, piston rod 18, piston 2, cylinder liner 19, hydraulic cylinder In the device 8, the slider 15 is slidably installed in the upper and lower guide plates 16a, 16b in the casing 10, the crankshaft connecting rod 14 drives the slider 15 to move back and forth, and the slider 15 is connected to the piston rod 18 through the transmission rod 17 to drive the piston 2 in the cylinder liner 19. The internal reciprocating sliding movement works, the piston 2 is composed of at least two piston rings, a sealing ring 3 composed of three petals, a spring ring 4, a compensating thrust spring 5, and a baffle 6. The piston 2 is preferably composed of three piston rings 21 . The sealing ring composed of three petals is embraced in the groove 31 of the groove 31, and the compensation spring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap