Screw structure

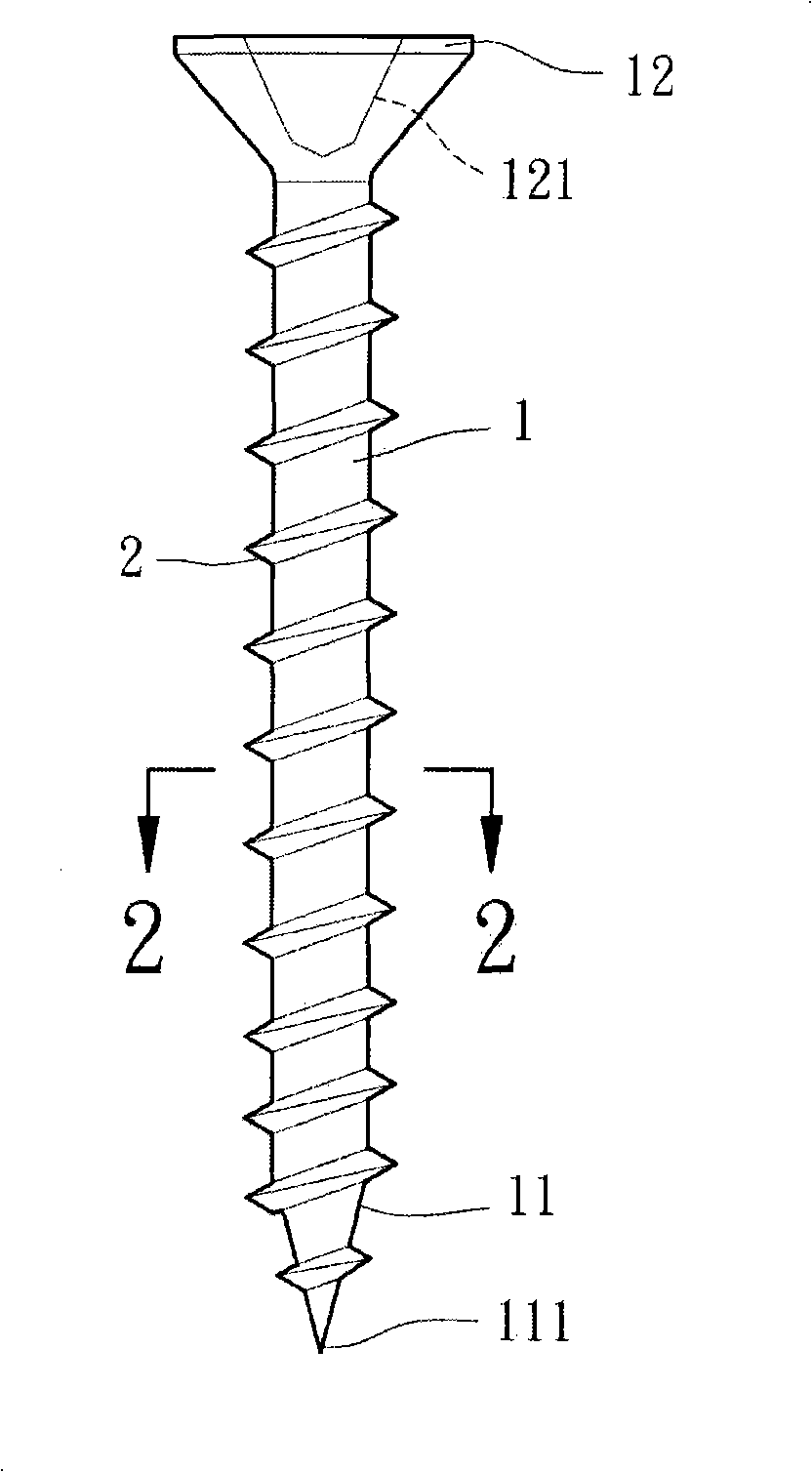

A technology of structure and screw, which is applied in the field of screw structure, and can solve problems such as the skew of the rod body 1, damage to the screw quality, and increased resistance of the threaded part 2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention, together with the accompanying formula, are described in detail as follows:

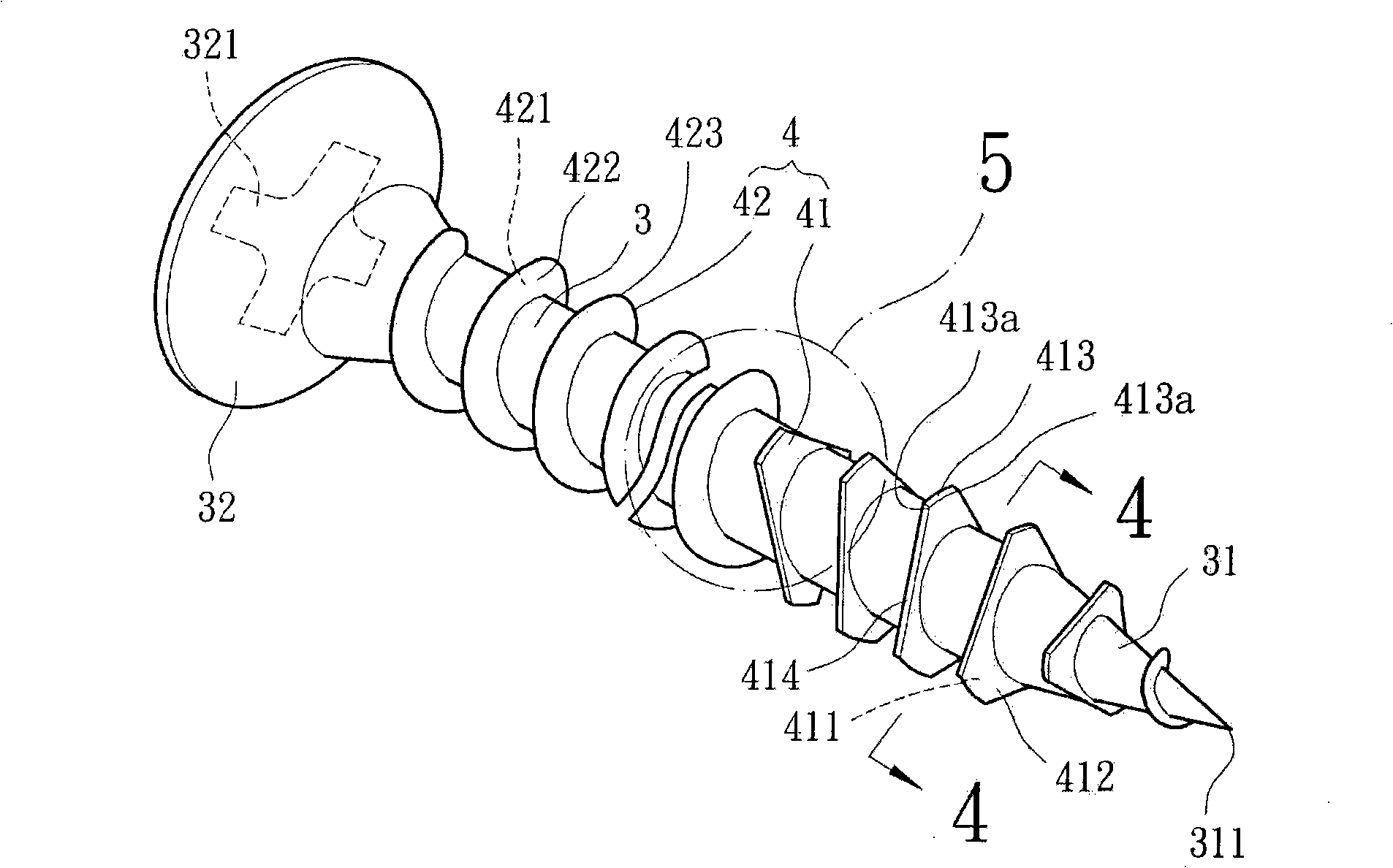

[0022] Please refer to image 3 , 4 As shown, the screw structure of the preferred embodiment of the present invention includes a rod body 3 and a threaded portion 4 , the rod body 3 is in the shape of a round rod, one end of the rod body 3 forms a tapered surface 31 , and the other end is provided with a head 32 . The tapered surface 31 has a tip 311 located at the end of the tapered surface 31 , which abuts against the surface of an object (not shown) to perform hole reaming action. The top of this head 32 offers a driving groove 321, and this driving groove 321 can be selected from the geometry structures such as inline, cross or regular polygon, and it can be used for inserting a tool (not shown, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com