Data transfer control method between blast furnace feeding system and blast furnace cloth system

A control method and feeding system technology, applied in the direction of electrical program control, program control in sequence/logic controller, clock and funnel arrangement, etc., can solve the problems of complex adjustment process and large adverse impact on blast furnace production, and achieve Effects of improving stability, simplifying furnace top material distribution control system, and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

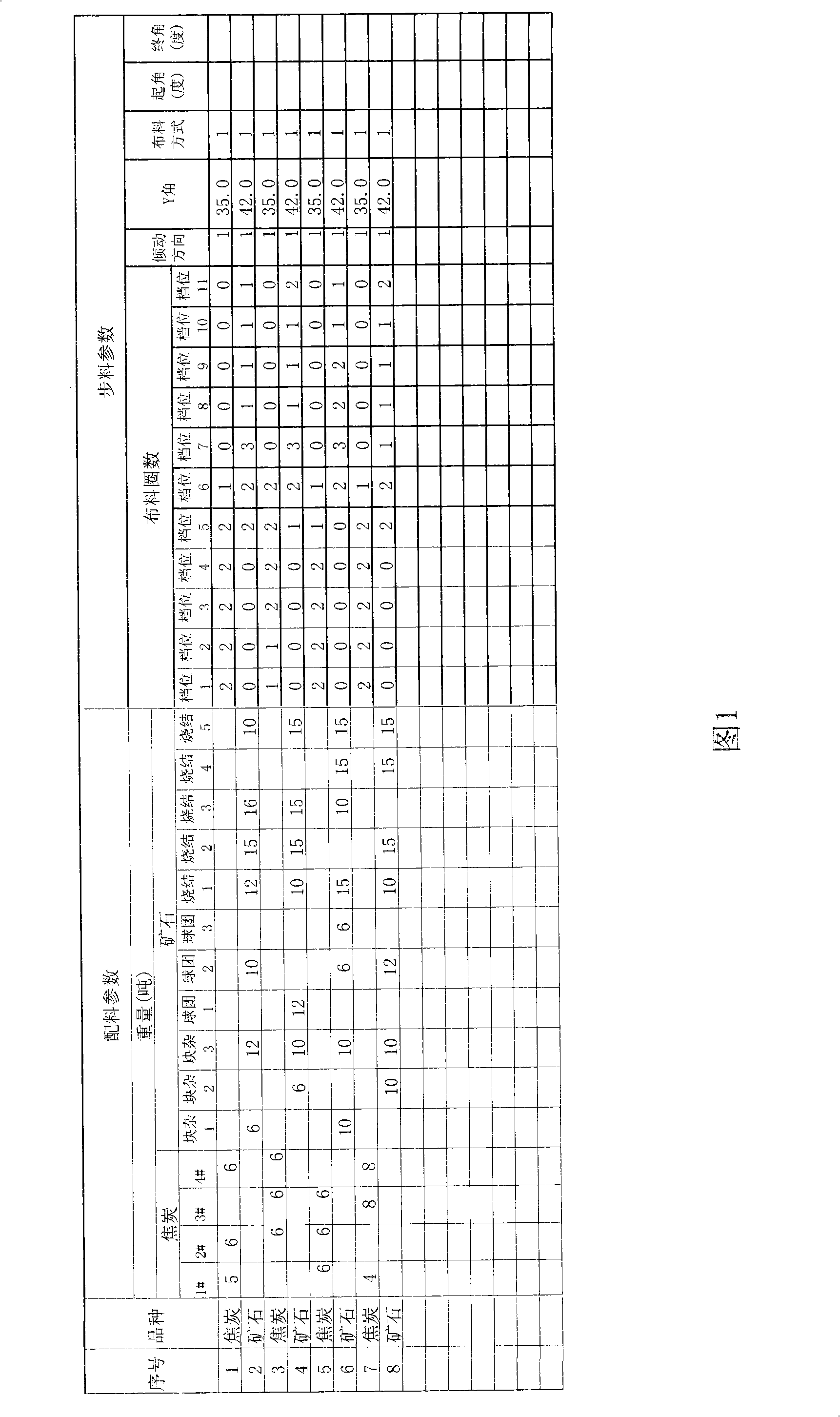

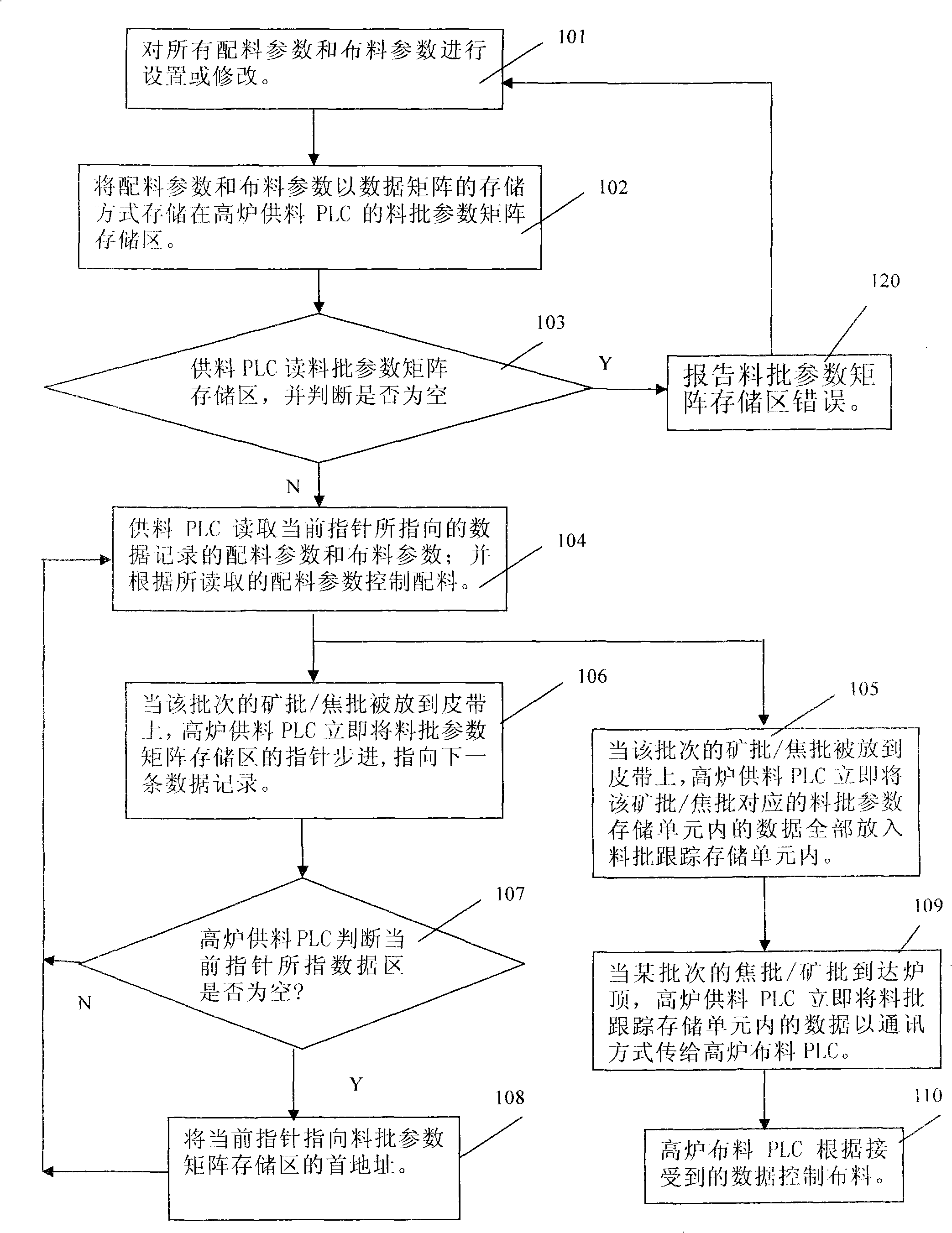

[0022] As shown in Figure 1, the process method usually adopted by large-scale material-free bell blast furnaces is a batch of coke "C", a batch of ore "O", or a batch of ore "O" and a batch of coke "C". Among them, the ore batch is composed of sintering, pellets and lump ore, etc., and the charging system is O↓C↓ or C↓O↓. A batch of ore and a batch of coke are loaded on the top of the furnace to form a large batch (Charge), which goes round and round. For a 2,000 cubic meter blast furnace, the batch weight of the charge is: coke batch weight 17.5t, ore batch weight 83.3t. Under normal circumstances, 7~8 large batches of materials (Charge) per hour. After each batch of coke / ore reaches the top of the furnace, it is put into the blast furnace body from the distribution chute according to the corresponding distribution method according to the different components of the batch. The composition of the material batch is controlled by the batching parameters, and the distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com