Intumescent seal

A technology of expansion and sealing parts, which is applied in the direction of sealing devices, vehicle parts, diaphragms, etc., and can solve problems such as difficult-to-form strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A 16 mm co-rotating twin-screw extruder was fed 400 g / h of EVA with a melt index of 3 and 40% acetate, 300 g / h of neutral expandable graphite (NGS), 250 g of melamine borate via a metering feeder (Brabender twin-screw) / h, ammonium polyphosphate 50g / h, aluminum oxide hydrate 50g / h, carbon black 1g / h, so as to obtain a base material with a thickness of 2mm and a width of 30mm. The expansion properties were determined by measuring the expansion ratio, ie the ratio between the final height and the initial height of a 50 mm diameter sample placed in a muffle furnace at 350°C, 450°C and 550°C for 30 minutes respectively.

[0089] In this measurement, the sample is placed at the bottom of a steel cylinder of the same diameter. The measurement is made both on a sample that expands freely (free expansion) and also on a sample with a weight of 100 g placed thereon (expansion under load). The results are shown in Table 1.

[0090] Table 1

[0091] temperature

[009...

Embodiment 2-15

[0095] Using the extruder and measurement system of Example 1, seals were prepared from the blends shown in Tables 2, 3 and 4, and measurements were taken to provide the expansion results shown in these tables. In these tables, vinyl acetate-containing polymers are conveniently characterized by two numbers, the melt index (MI) according to ASTM, and the amount of vinyl acetate present. For example 3 / 40 means a melt index of 3 and 40% vinyl acetate.

[0096] The expanded graphite used in the following examples is sold by Faima (Milan, Italy), UCAR (USA), NGS (Germany).

[0097] Table 2

[0098] Example

[0099] 450℃

[0100] table 3

[0101] Example

[0102] Table 4

[0103] Example

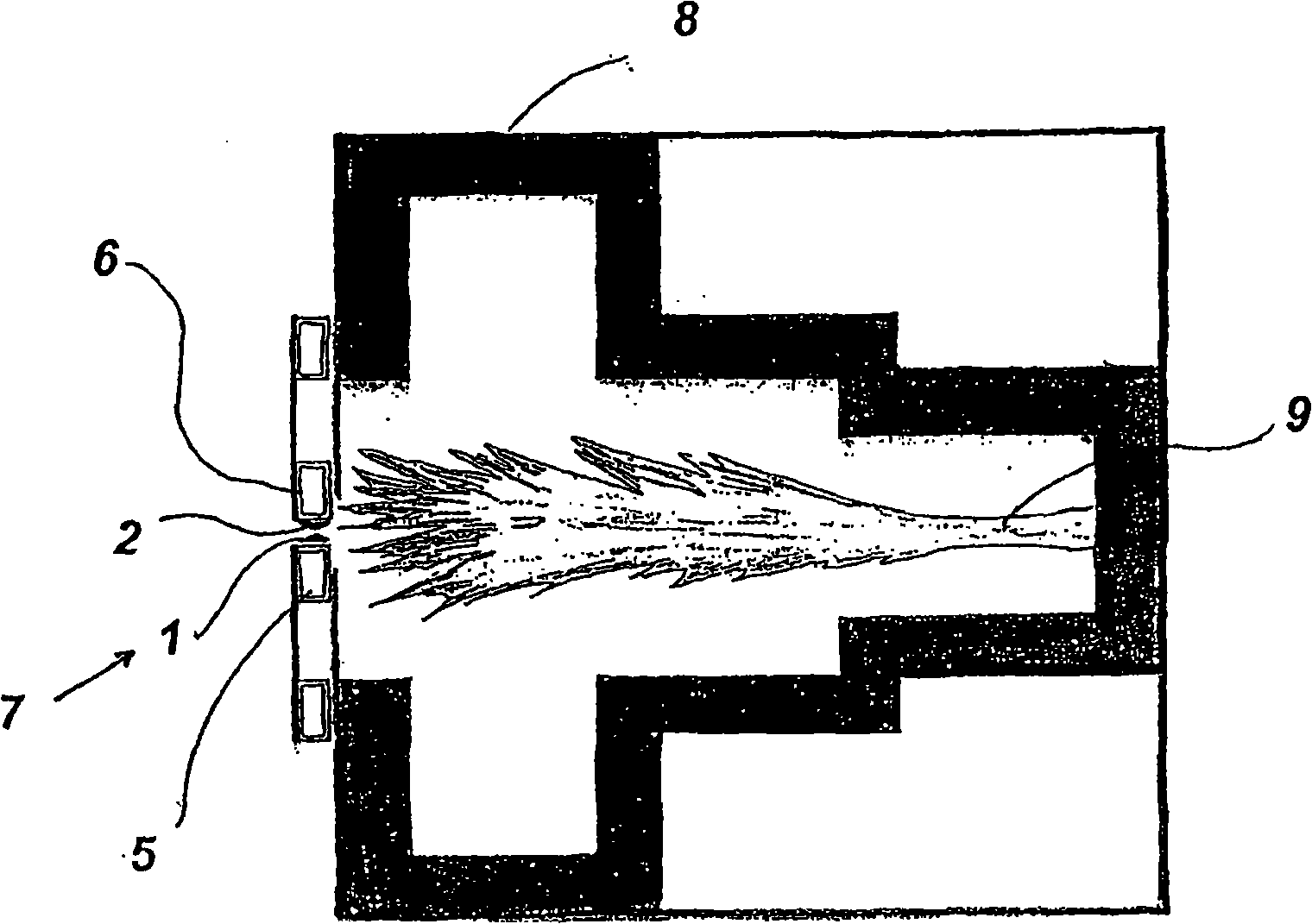

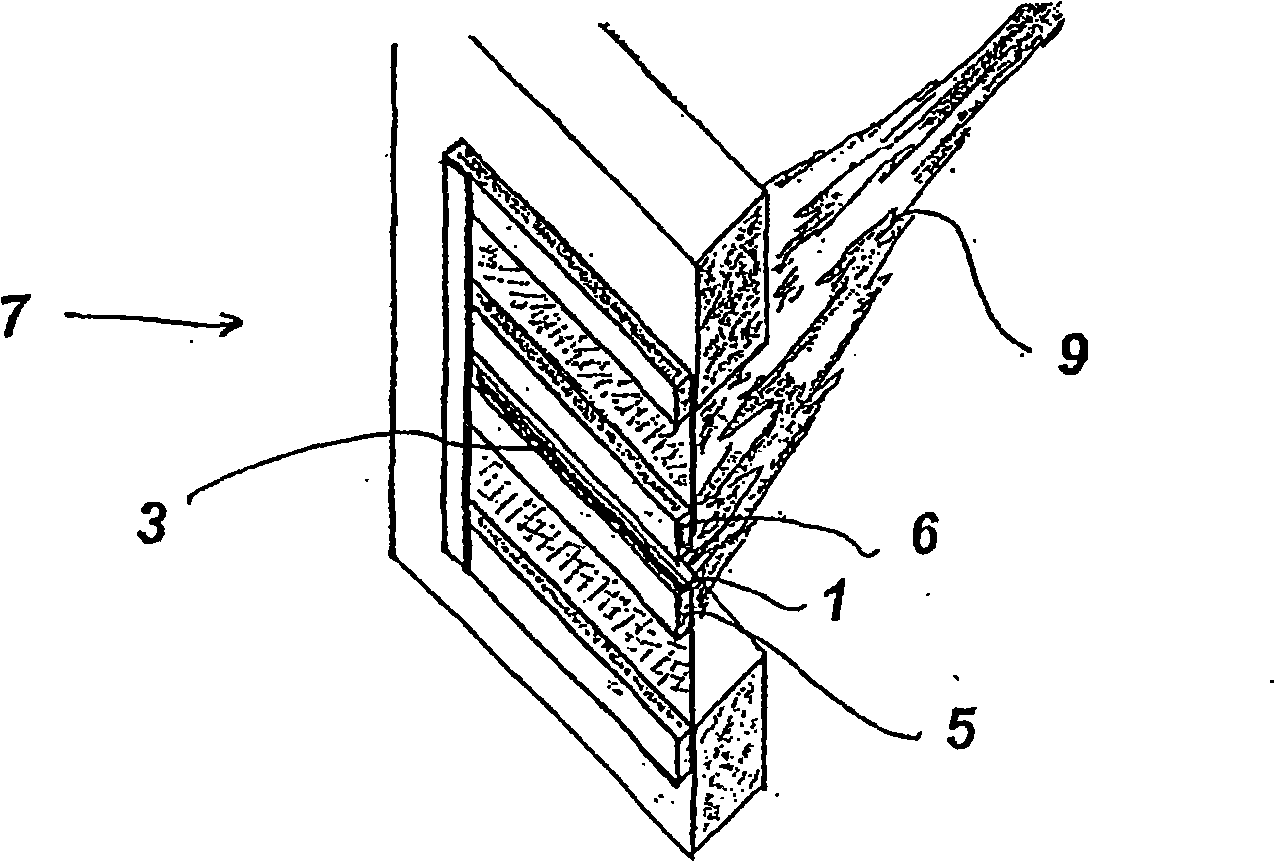

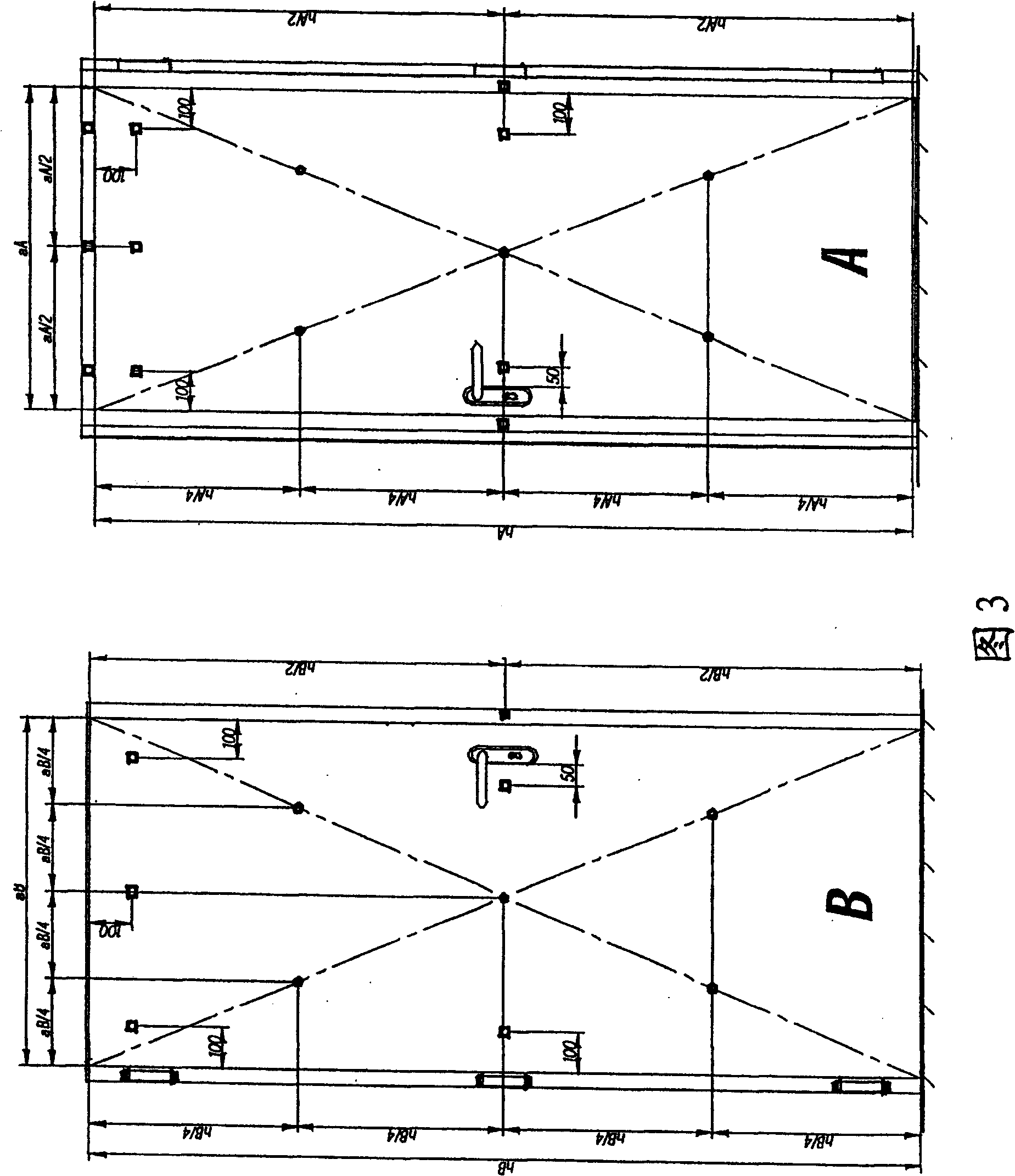

[0104] refer to figure 1 and 2Two expansion sealing strips 1, 2 of 20 mm wide and 1.5 mm high extruded from the formulations of Examples 1, 3, 6, 15, 16 have been placed on the sides 3, 2 of the two frames 5, 6 at a distance of 20 mm. 4, the frame is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com