Health-and-hygiene appliance comprising a dispersible component

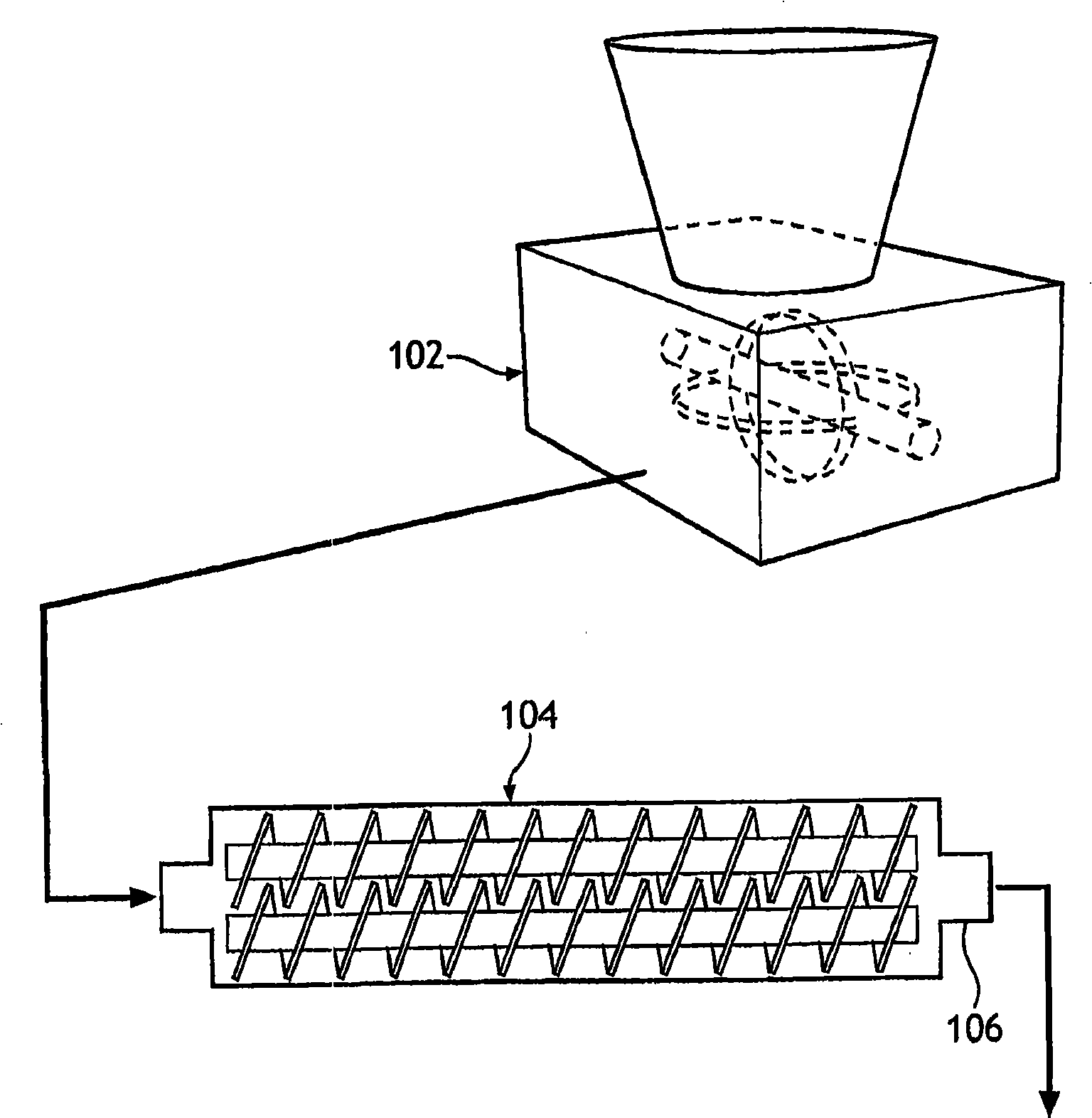

A technology for dispersing components and sanitary appliances, used in the field of health and sanitary appliances, and can solve problems such as hardening and distribution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

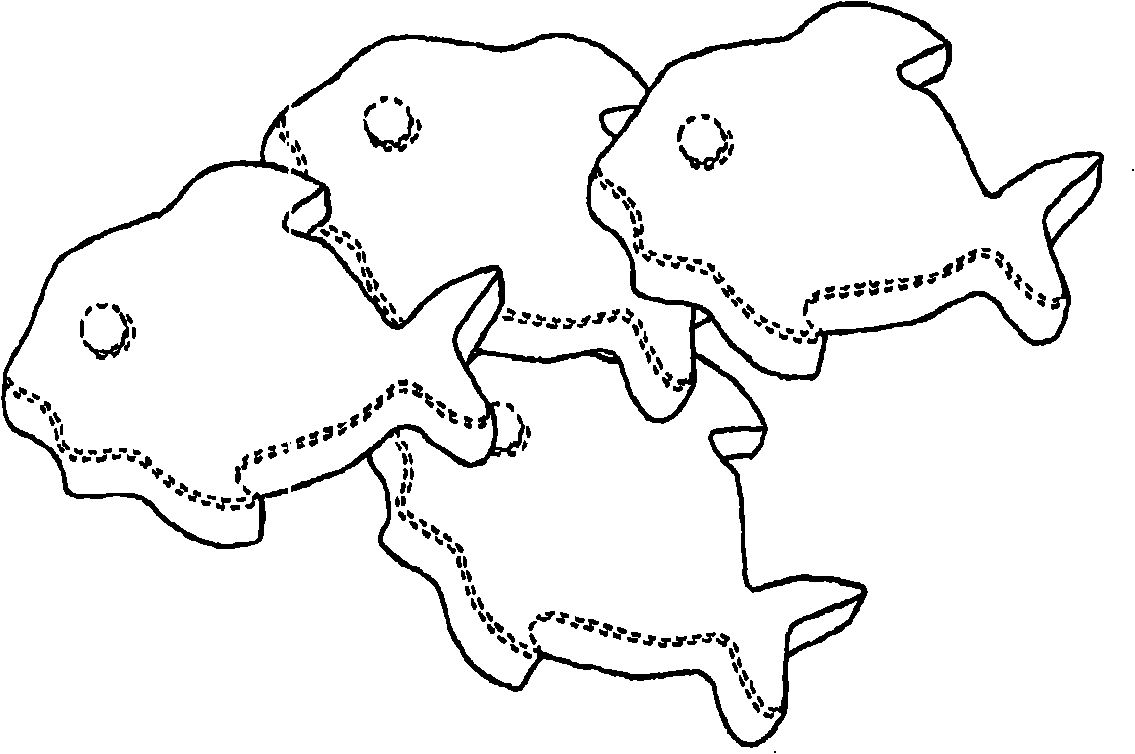

[0120] Take by weighing 10 pieces of ECO-FOAM brand loosely packed swelling foam (puff) (i.e. water-soluble degradable extruded cornstarch swelling foam, manufactured by National Starch and Chemical Company) as a dispersible component, then as a group with an oil ring pump ( An Oil-O-Pump) sprayer (supplied by Gemco, Product No. 7925) was sprayed with water. These blisters are cylindrical, about 1.5 inches long, about 0.5 inches in diameter, and have a calculated volume of about 0.3 cubic inches. The resulting ECO-FOAM foam surface has been wetted with water, and the water has started to interact with the chemical composition of the foam itself, so it is very sticky, allowing the soap coating to adhere. The dry weight of the expanded foam is 1.38g, and the wet weight is 1.45g.

[0121] These 10 sheets of water misted ECO-FOAM intumescent foam were then placed in a 1 gallon Ziplock bag containing approximately 2.5 g of the mixture of surfactant and colorant (i.e., the cleaning...

Embodiment 2

[0125] In this example, the same materials and treatment steps used in Example 1 were used, but each piece of ECO-FOAM accumulated expansion foam was sprayed with water mist and coated with cleaning agent separately. The average dry weight of each sheet of swelling foam before spraying water mist is 0.12g; the average weight of each swelling foam after spraying water spray is 0.17g; It is 0.37g. A more uniform coating was obtained, with an average coating of about 0.20 g of cleaning formulation on each piece of ECO-FOAM intumescent foam. The releasable component accounted for 68% of the total weight in the wet state and 54% of the total dry weight.

Embodiment 3

[0127] Canola oil was coated on the ECO-FOAM bulk expansion foam (dispersible component) by various methods. Canola oil is used because it does not dissolve the ECO-FOAM foam. ECO-FOAM intumescent foams were individually treated with canola oil and then placed in Styrofoam cups filled with an excess of the cleaning formulation of Example 1 (releasable component). Put the lid on the cup and shake the contents to coat the ECO-FOAM foam. Then remove the utensil and repeat. The table below shows the results for various coating methods.

[0128] method

Foam (g)

bubble+

oil (g)

foam+oil+

cleaning preparation

(g)

Coating weight

% of total weight

Cleaning preparation weight

% of total weight

Dipping and Coating 1

0.14

2.66

3.37

93%

21%

Dipping and Coating 1

0.12

1.01

1.27

91%

20%

dipping, wiping and

coating 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com