Safe wrench structure

A safety wrench and shaft technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of operators falling, breaking, poor practicability, etc., to avoid the effect of losing the center of gravity and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

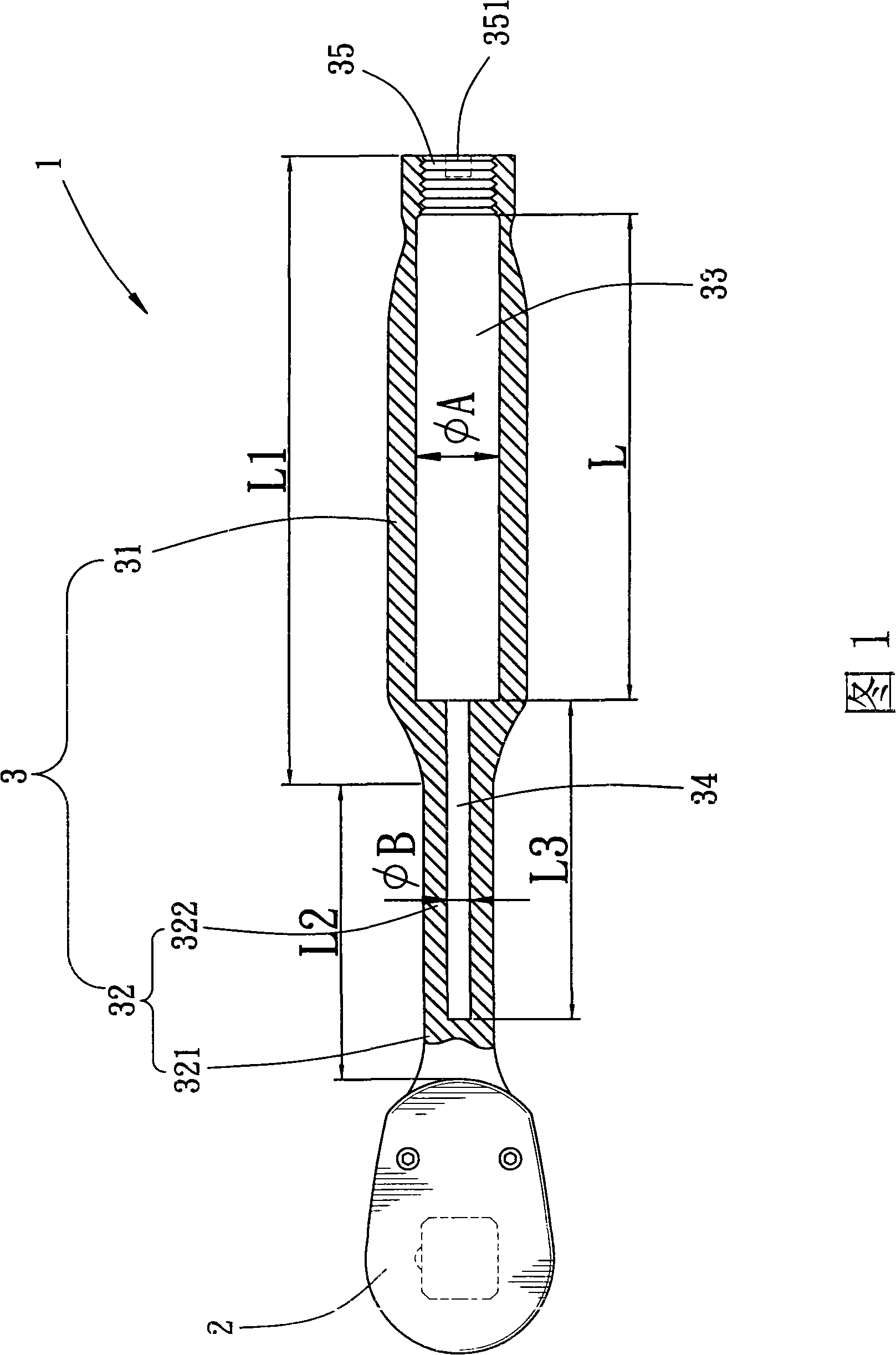

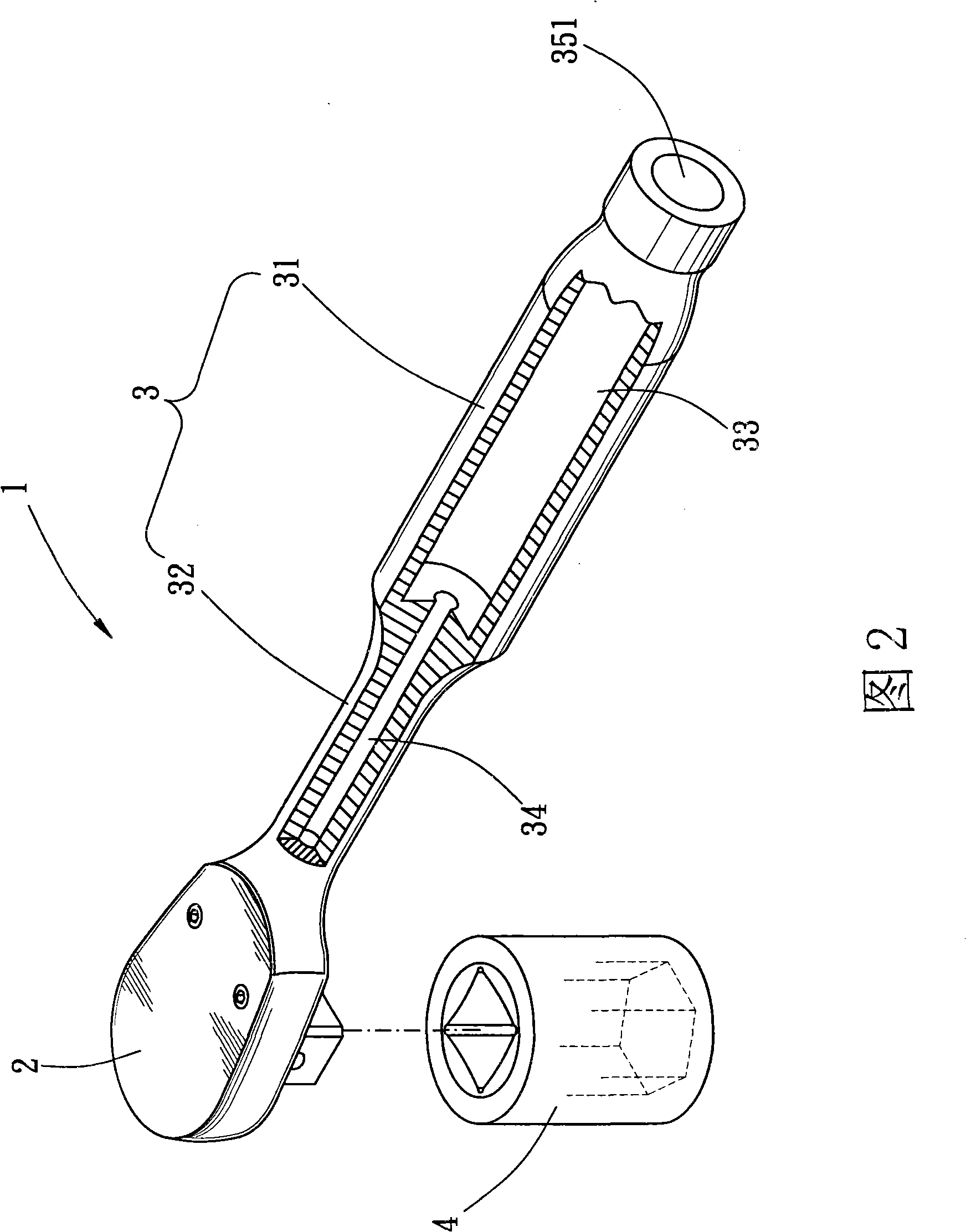

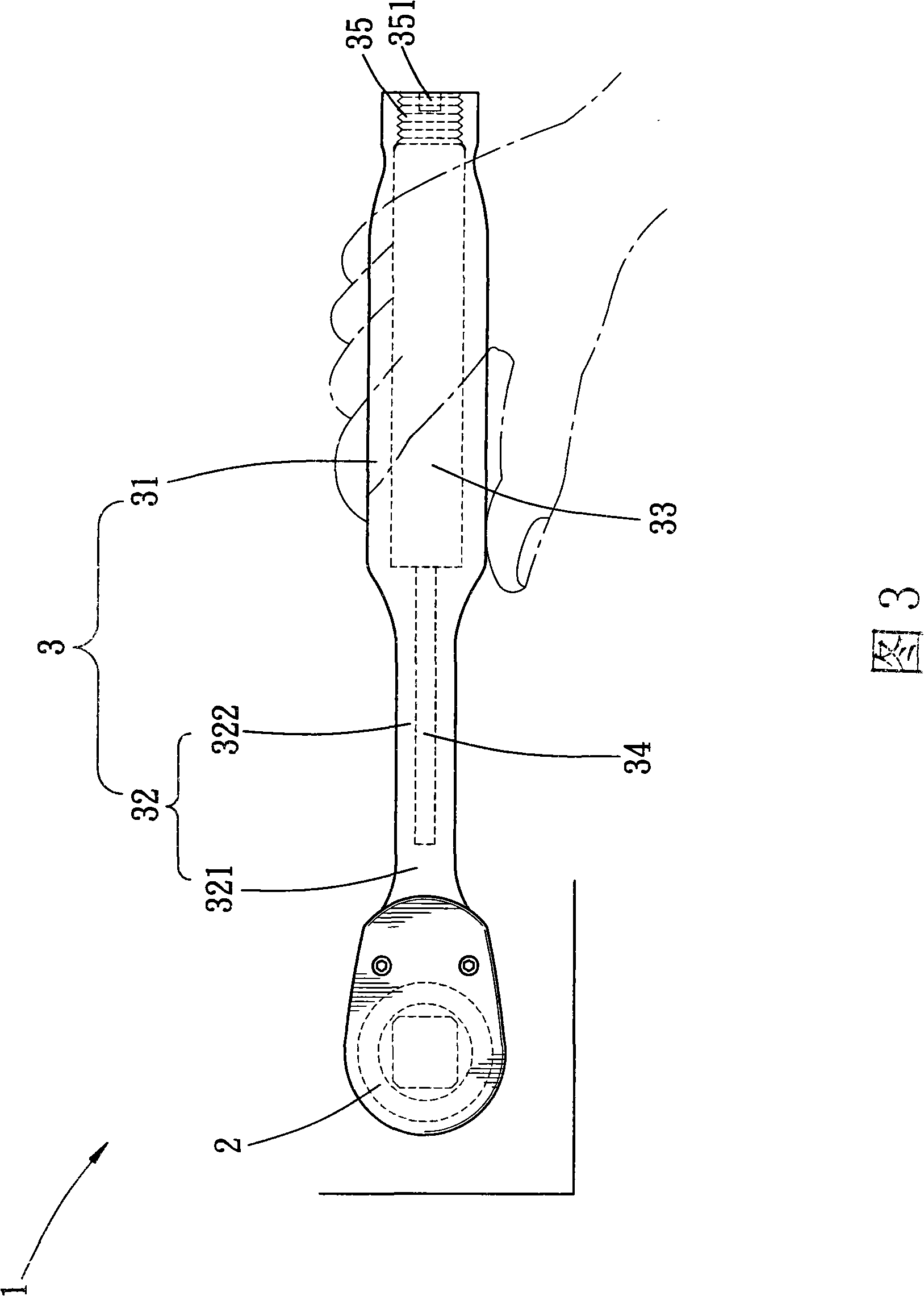

[0029] The present invention relates to a safety wrench structure, please refer to Fig. 1 and Fig. 2, its body 1 includes a head 2 and a handle 3, wherein:

[0030] The head 2 is provided with a fixing part 4 for locking, and it is connected with the handle 3, so that when the head 2 and the fixing part 4 are locked, the user applies force on the end of the handle 3 opposite to the head 2, and Make the body 1 generate torque with the head 2 as the fulcrum, so that the fixing part 4 is locked into the object along the rotation direction of the torsion force, and at this time the fixing part 4 also returns the reaction torque to the body 1, and causes a shear force on the body 1 and torque;

[0031] The handle 3 is assembled with the head 2, and the handle 3 has a first shaft 31 and a second shaft 32, the first shaft 31 is thicker than the second shaft 32, the first shaft The joint between the body 31 and the second shaft 32 is tapered toward the second shaft 32 and is thicker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com