Telescoping clamp assembly

A telescopic, clamp technology, used in manufacturing tools, claw arms, manipulators, etc., to solve problems such as loosening and unintentional disassembly of clamp components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or use of the present invention.

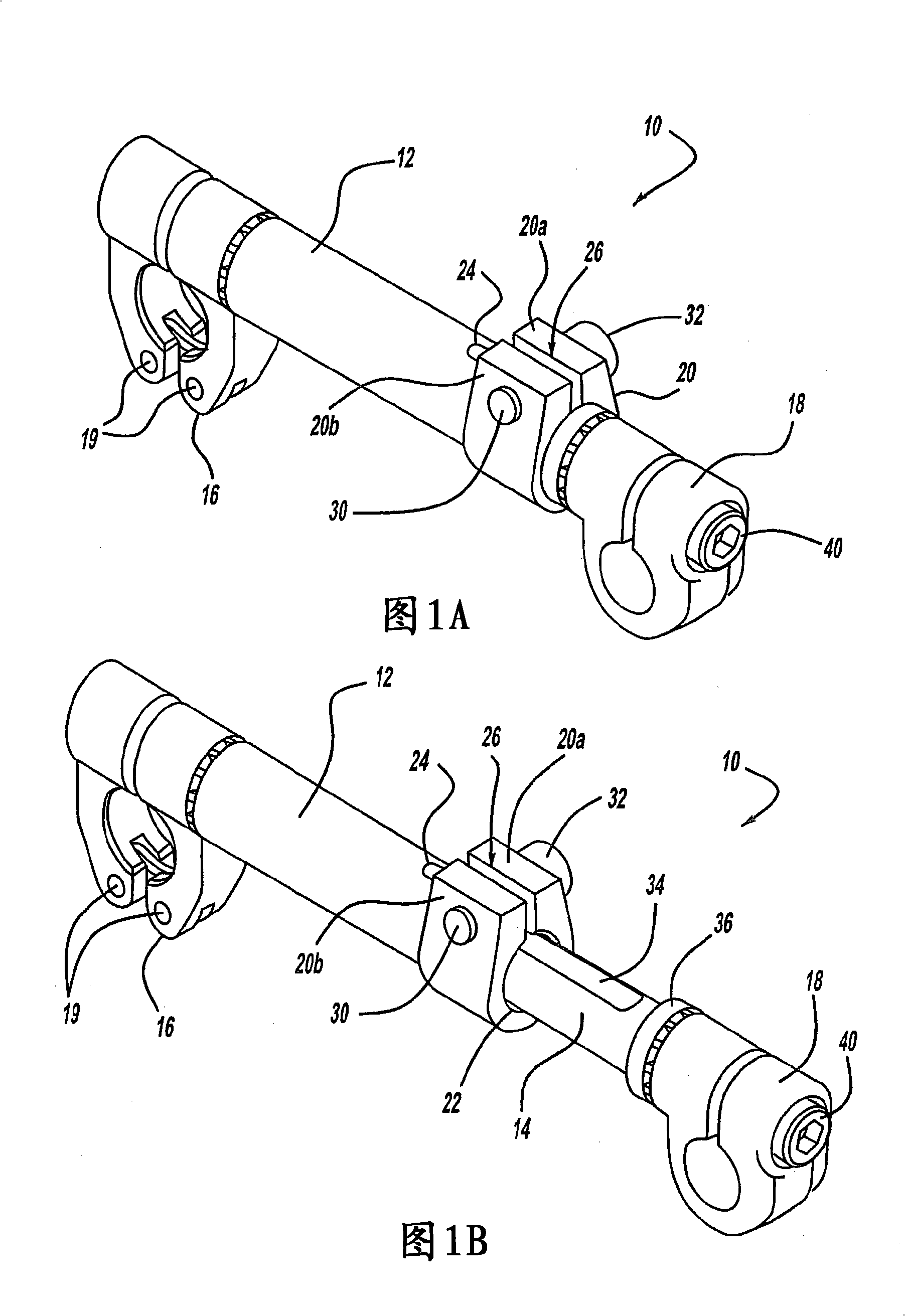

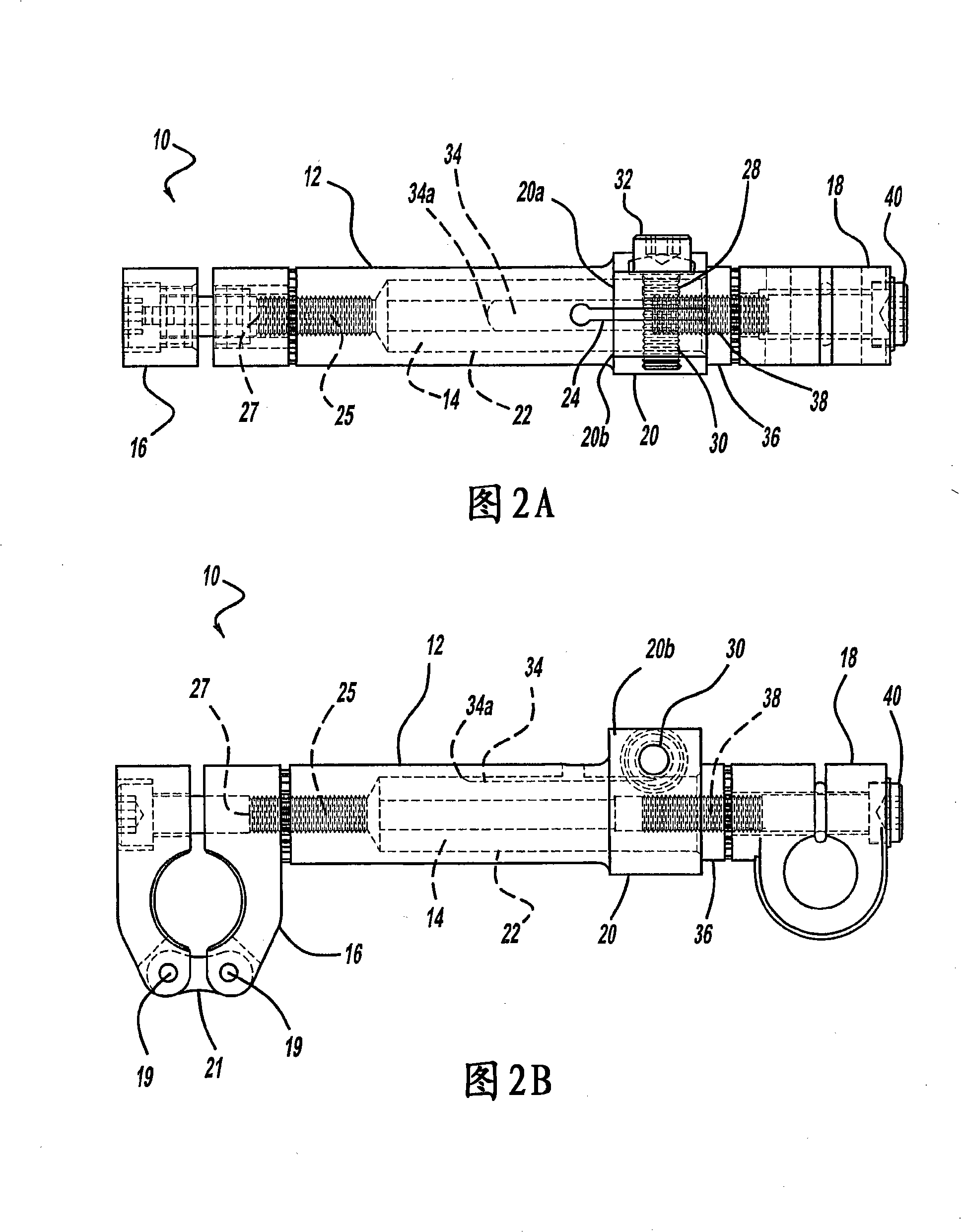

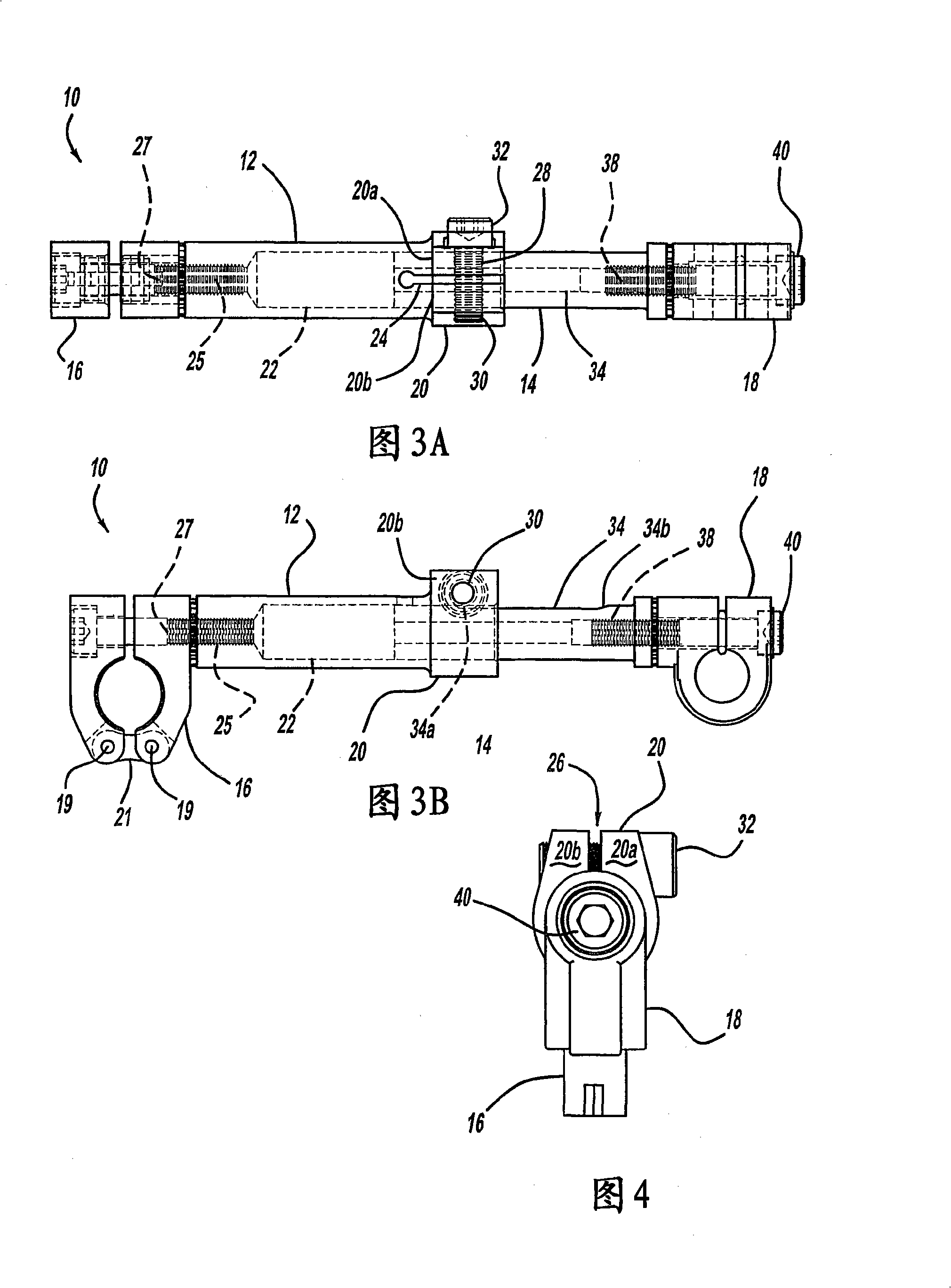

[0023] Referring now to the drawings and the exemplary embodiments illustrated therein, a telescopic clamp assembly 10 for a material handling system includes an outer shaft or tube 12 that is telescopically engaged with an inner shaft or telescopic shaft 14 (FIG. 1B ). The tube 12 and the telescopic shaft 14 can be adjusted relative to each other to adjust the length of the telescopic clamp assembly 10 between the retracted length (Figures 1A, 2A, and 2B) and the extended length (Figures 1B, 3A, and 3B). When at the required degree of extension, as will be explained below, the telescopic shaft 14 may be fixed with respect to the tube 12 via a holder, or a clamp, or a pin, or a bolt, or a fastener 32. The fastener 32 is also used to restrict the inner shaft from extending and / or pulling out of the outer shaft, which will be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com