Double-mold hydraulic press capable of quick changing mold

A technology of hydraulic press and double template, applied in the direction of presses, manufacturing tools, etc., can solve the problems of long downtime, great impact on production efficiency, inability to meet production needs, etc., to improve productivity, improve accuracy and coordination, shorten the Effect of Die Change Assist Time

Active Publication Date: 2010-12-01

HEFEI METALFORMING MACHINE TOOL

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to pursue the individualization of products, more and more products are developing in the direction of small batches and multiple varieties, so frequent mold replacement has a great impact on production efficiency

The traditional mold change method is to replace the mold, which must be replaced in the hydraulic press, so the downtime is very long, especially on the production line, which will have a great impact on the entire line, so this method of mold replacement cannot Adapt to the current rapid development of production needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

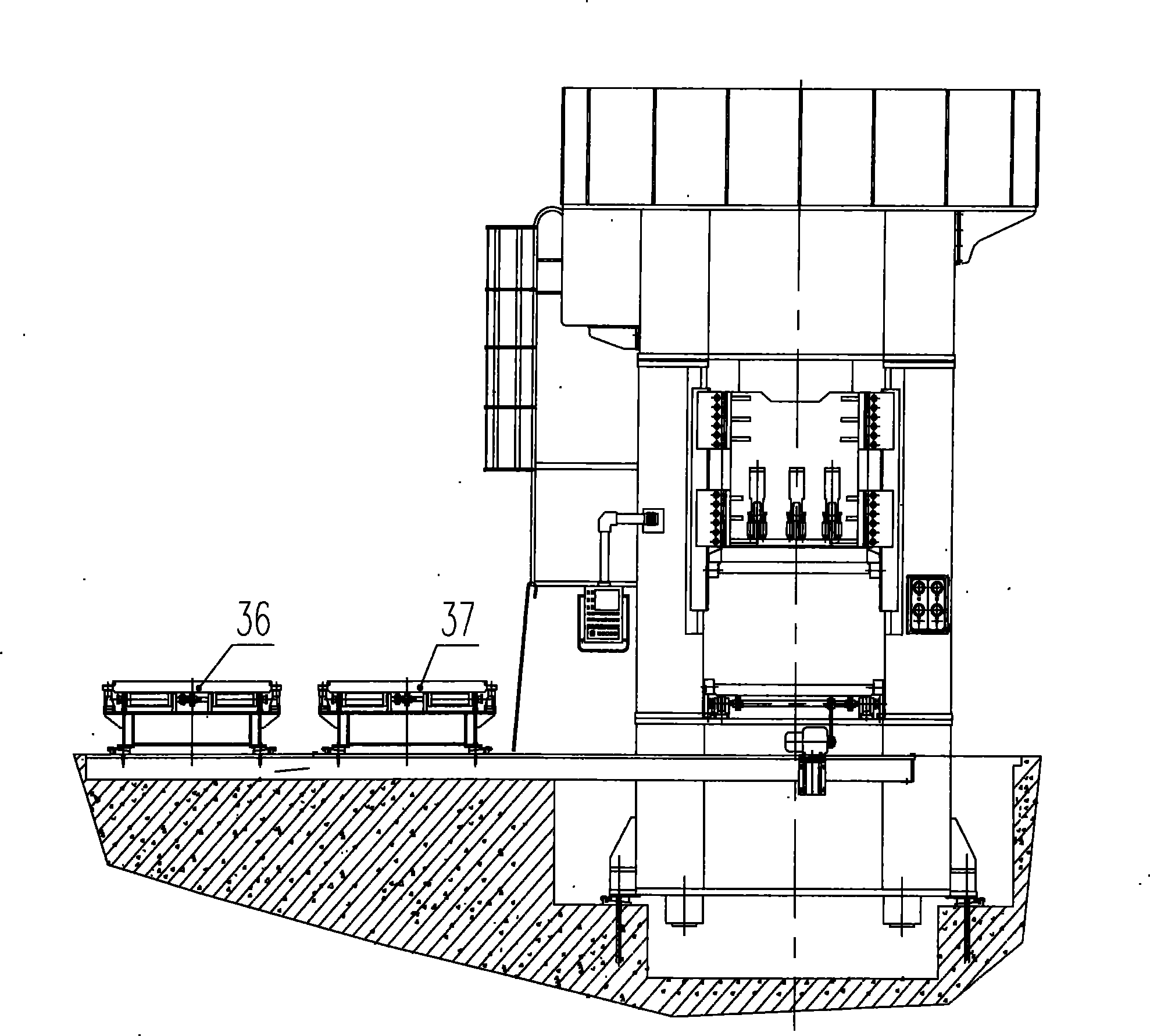

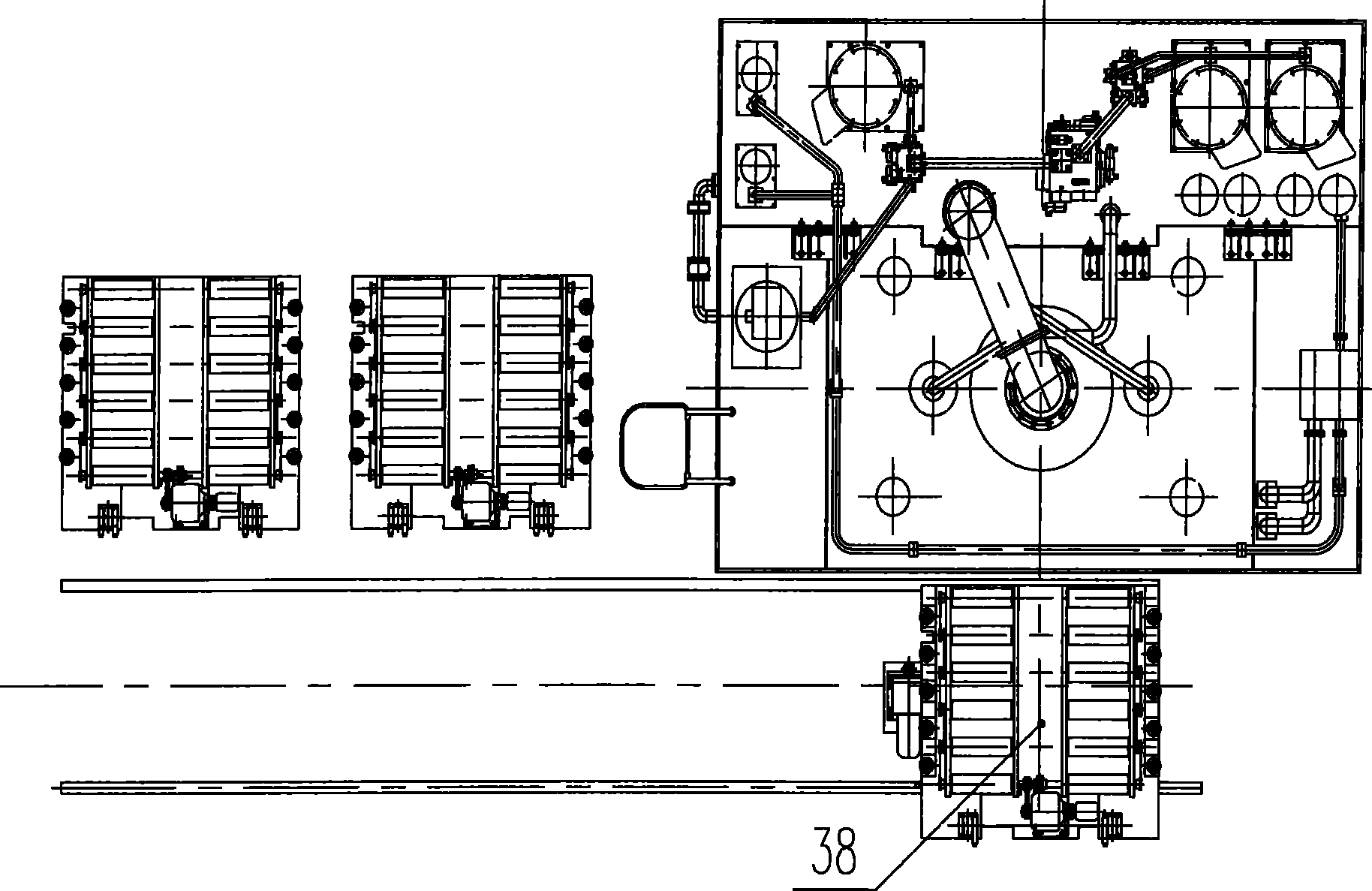

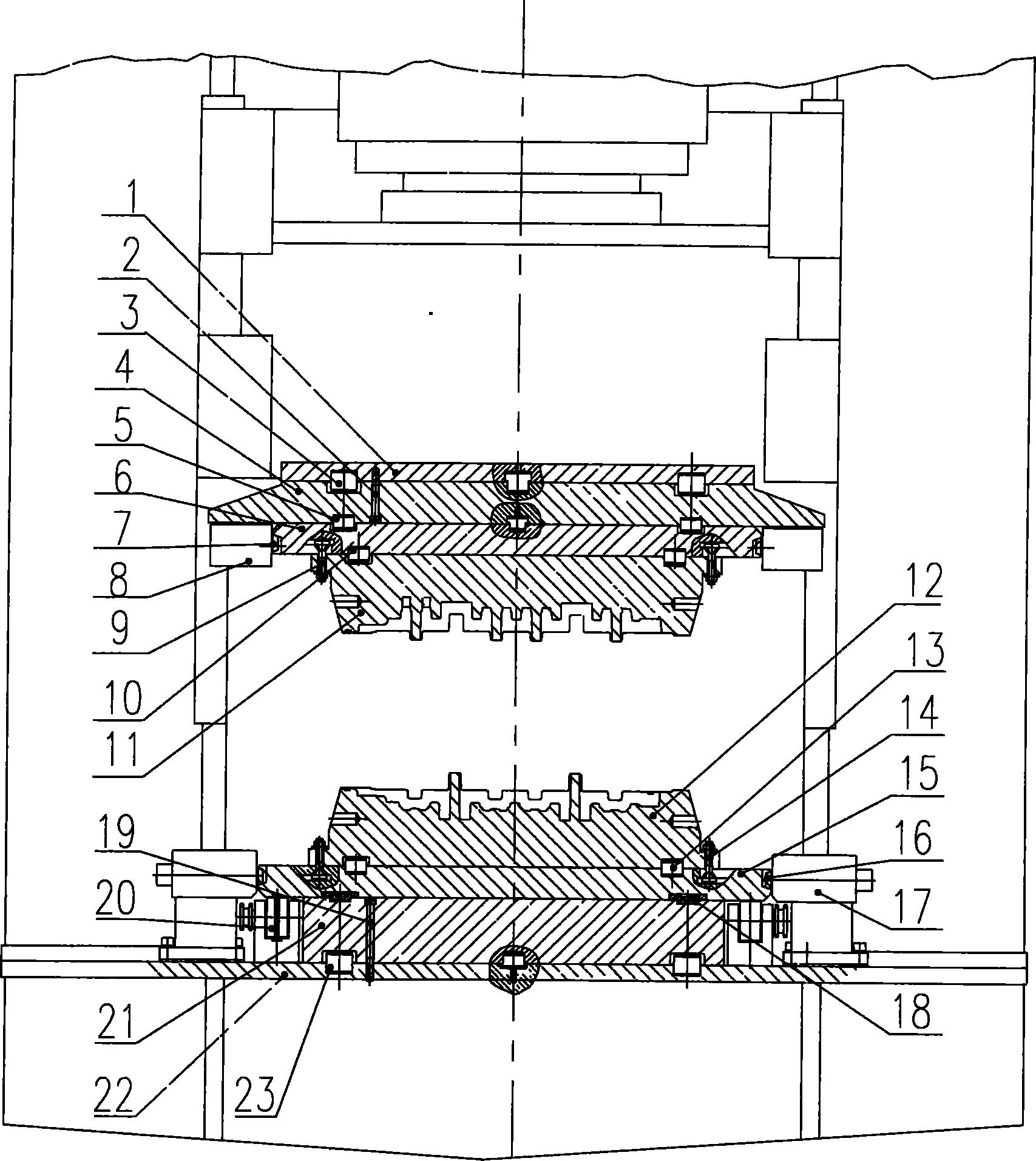

The invention relates to a hydraulic machine which is provided with a dual-formwork typed quick die replacing function and is characterized in that two sets of upper / lower die alternative changing installation dies, two sets of die storage platform and a die changing trolley are arranged in the hydraulic machine equipment of the continuous production line; when the first set of dies are arranged on the first set of formworks, the upper / lower formworks are closely locked on an upper fixed cushion plate and a lower fixed cushion plate by ten hydraulic locking cylinders. The hydraulic machine provides two sets of upper / lower formworks, alternatively replaces and installs the dies outside the host machine, subsequently uses the functional parts such as a hydraulic floating roller, two sets ofdie storage platforms, a die replacing trolley and a die automatic clamping part, and the like, conveniently and quickly replaces the dies, changes the traditional type in which the dies are replacedinside the host machine, improves the exactness and coordination of the process operation, greatly shortens the die-replacing auxiliary time, thus meeting the high requirements on the functions such as installation, transport, storage, etc. of quick replacement in the pipelining of online equipment.

Description

Hydraulic Press with Double Platen Quick Die Change Technical field: The present invention relates to a hydraulic press with a double-platen quick mold change. More specifically, this hydraulic press with a double-platen quick mold change can meet the installation, transportation and storage of quick-change molds in the assembly line operations of various line equipment. Functional high demands in the hydraulic press manufacturing industry. Background technique: It is currently known that a large number of various types of molds are required during the use of hydraulic presses. In order to pursue the personalization of products, more and more products are developing in the direction of small batches and multiple varieties. Therefore, frequent mold replacement has a great impact on production efficiency. The traditional mold change method is to replace the mold, which must be replaced in the hydraulic press, so the downtime is very long, especially on the production line, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B30B15/02

Inventor 袁隆秀

Owner HEFEI METALFORMING MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com