Polylactic acid jointing plate and manufacture method thereof

A manufacturing method and polylactic acid technology, applied in chemical instruments and methods, decorative arts, lamination devices, etc., can solve problems such as non-conformity with environmental protection, and achieve the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, The manufacturing method, steps, features and effects thereof are described in detail below.

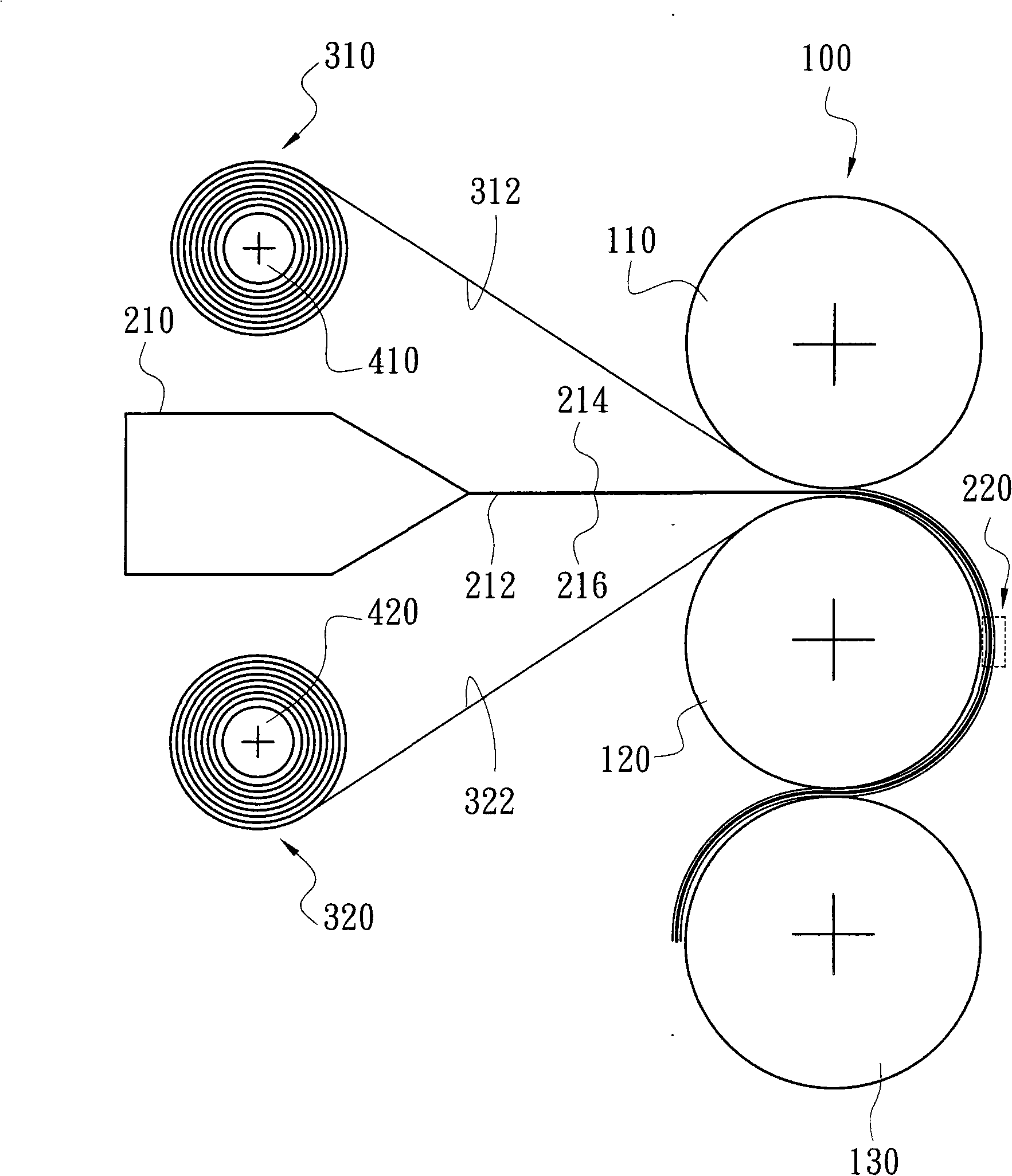

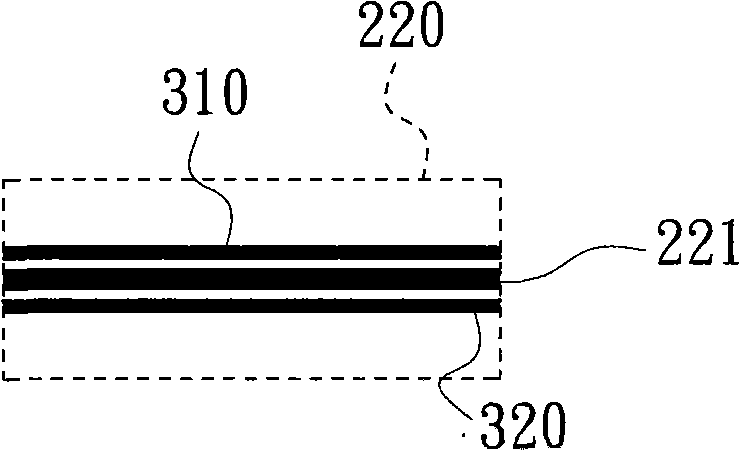

[0050]The polylactic acid laminated board of the present invention comprises a polylactic acid board and a polylactic acid film, and the polylactic acid film is attached to at least one surface of the polylactic acid board. The manufacturing method of the polylactic acid laminated board includes forming a polylactic acid board and a polylactic acid film, mainly using temperature to make the polylactic acid film adhere to at least one surface of the polylactic acid board while pressing the board, and combine it into a polylactic acid laminated board .

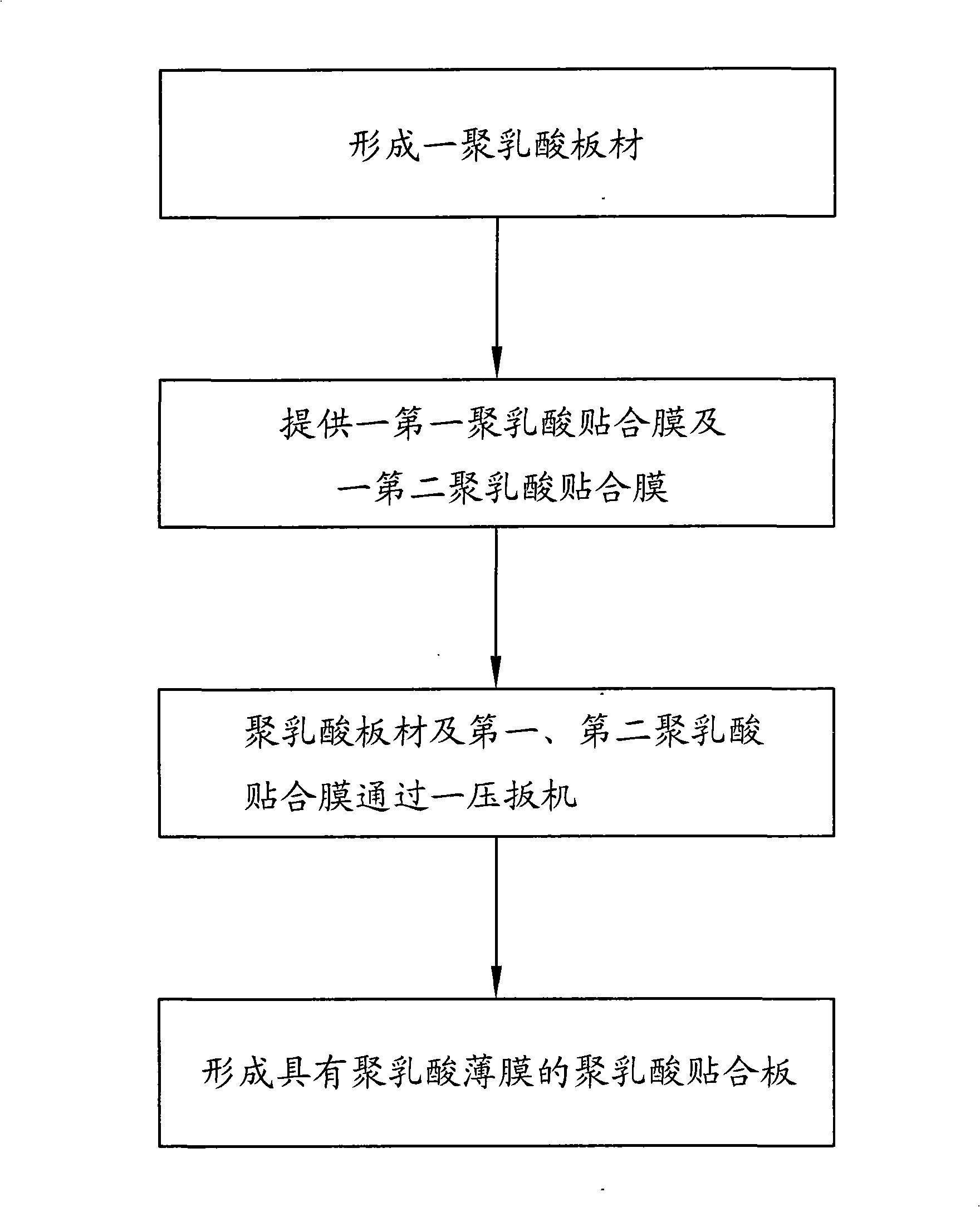

[0051] see figure 1 and Figure 2A , figure 1 It is a flow chart showing the steps of making a polylactic acid laminated board according to an embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com