Single-block fluid injection device and production and control method thereof

A technology of fluid jetting and jetting device, applied in printing and other directions, which can solve the problems of inability to control the direction of ink droplets, increasing nozzle holes, and poor printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

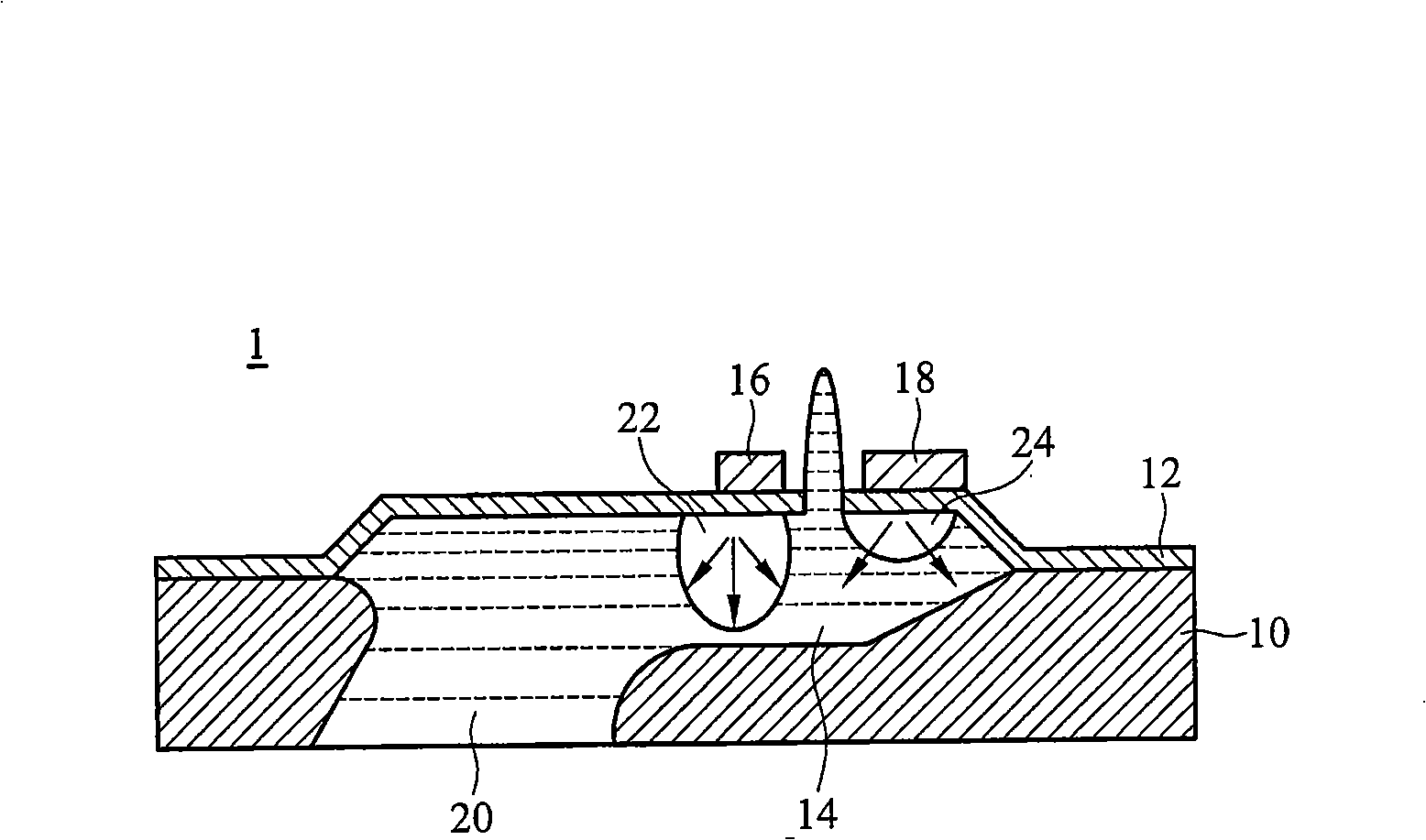

[0027] Next, detailed description will be given in conjunction with the accompanying drawings, so as to better understand the fluid ejection device and its manufacturing and control methods in the preferred embodiments of the present invention. It can be appreciated, however, that the present invention provides many inventive concepts that can be implemented in a wide variety of fields of application. The illustrative examples are merely illustrations of specific implementations utilizing the concepts of the present invention and do not limit the scope of the present invention.

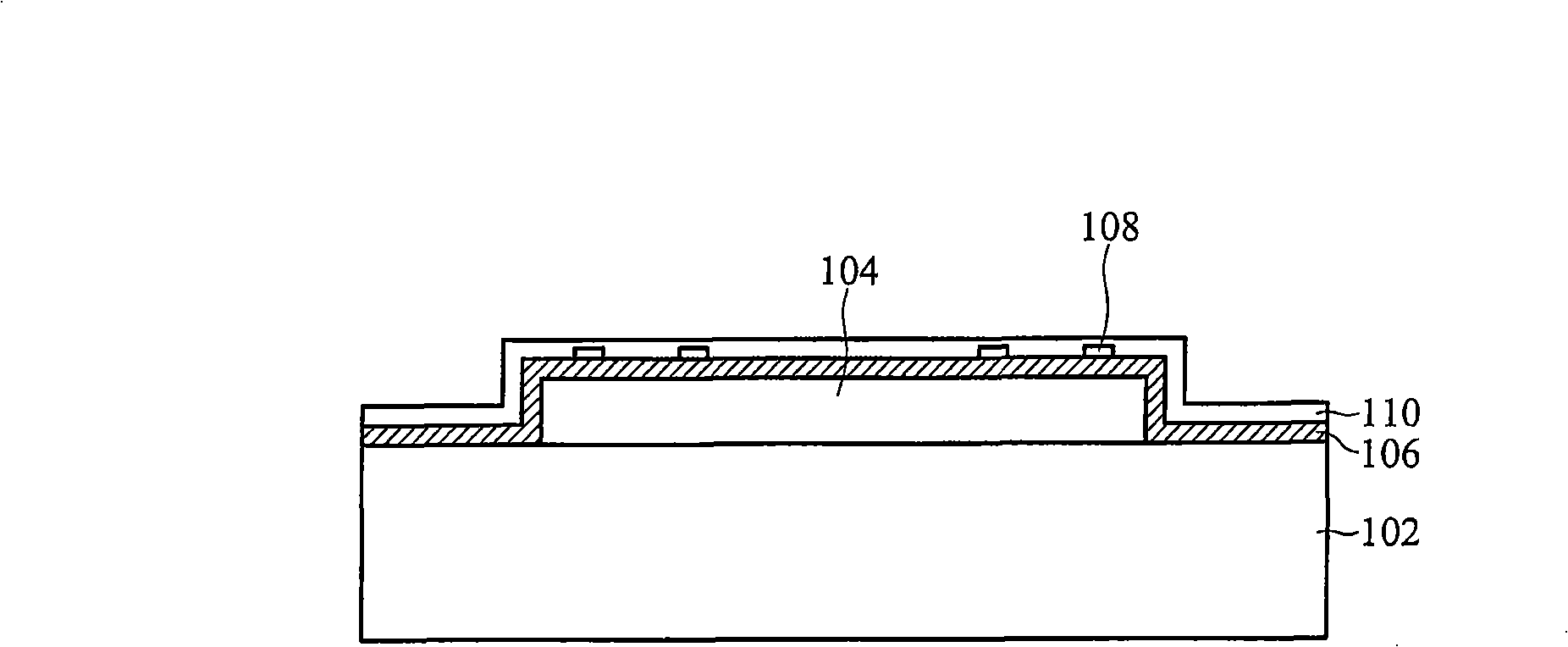

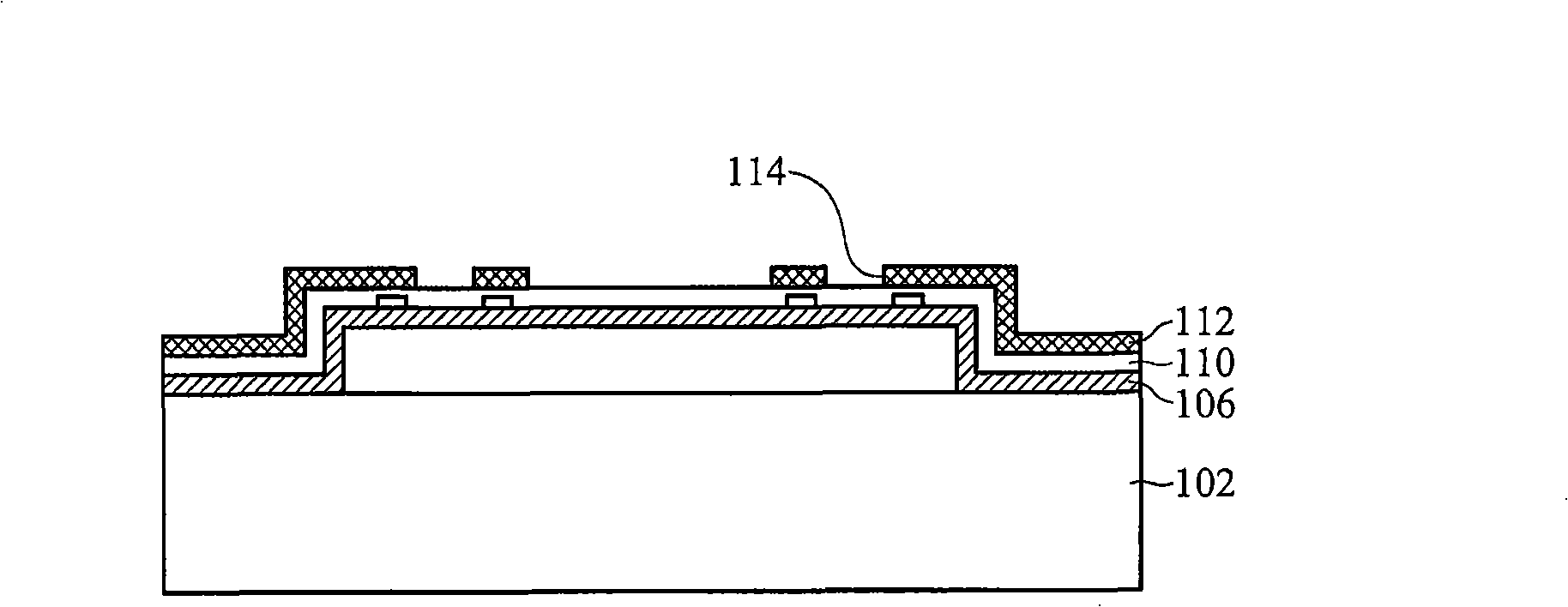

[0028] Figure 2A-Figure 2E A cross-sectional view of fabricating a monolithic fluid ejection device according to an embodiment of the invention is shown. Figure 2F A schematic bottom view showing an orifice of a monolithic fluid ejection device according to an embodiment of the present invention.

[0029] refer to Figure 2A , providing a substrate 102 , such as a monocrystalline silicon substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com