Chitosan oligosaccharide chelated ferrous preparation method and device

A preparation device and chitosan oligosaccharide technology are applied in the preparation of sugar derivatives, feeding devices, chemical instruments and methods, etc., which can solve the problems of low mixing efficiency, inability to continuously provide mixed solutions, long preparation time, etc., and achieve Improve the effect of blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

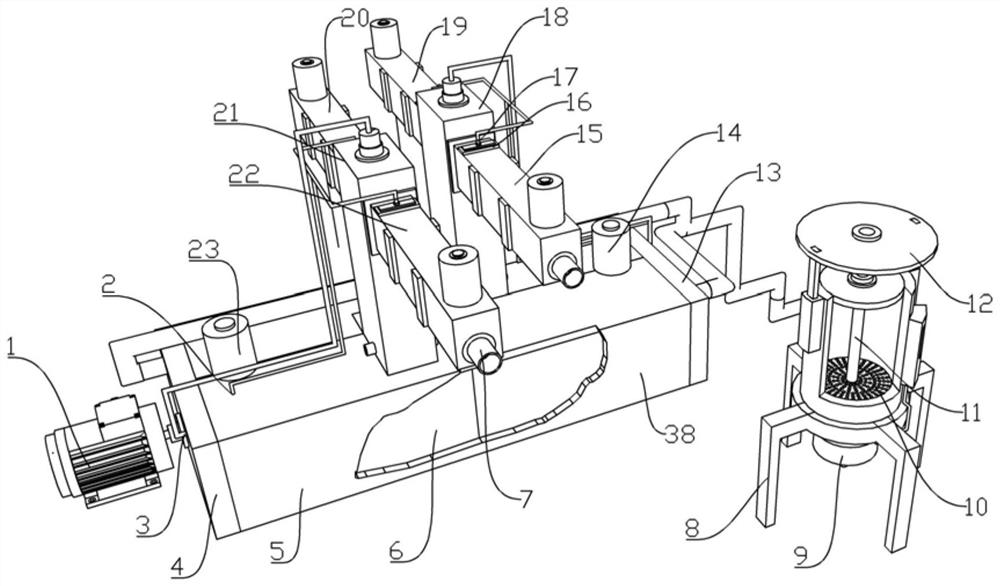

[0050] like Figure 1-6 Shown, a kind of chitosan oligosaccharide chelated ferrous preparation device, comprises the primary mixing tube, the secondary mixing tube and the mixing tank that are arranged successively from top to bottom, and the mixing tank is also connected with suction filtration device;

[0051] One end of the first-stage mixing pipe is connected with a water inlet pipe through a flow switch 7, and the upper part of the first-stage mixing pipe is also provided with a delivery box for quantitative delivery. Mixed stirring structure, the other end of the primary mixing tube is connected to the side wall of the secondary mixing tube;

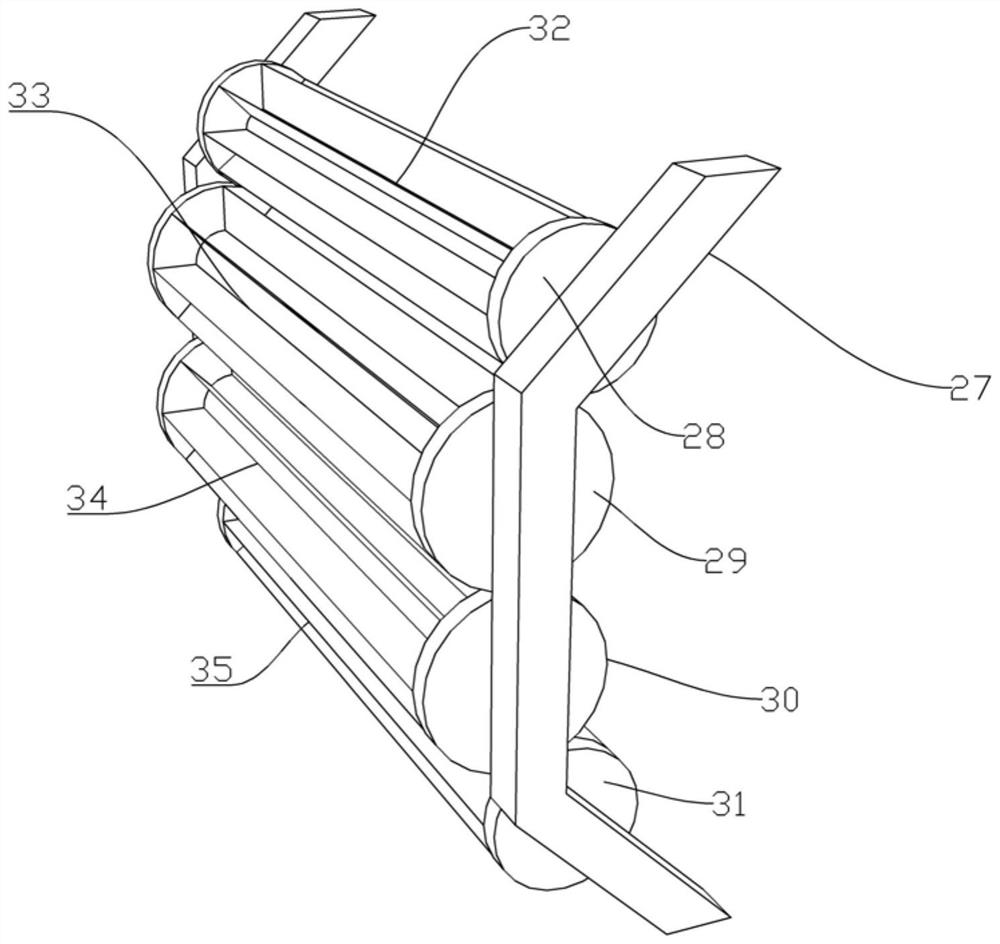

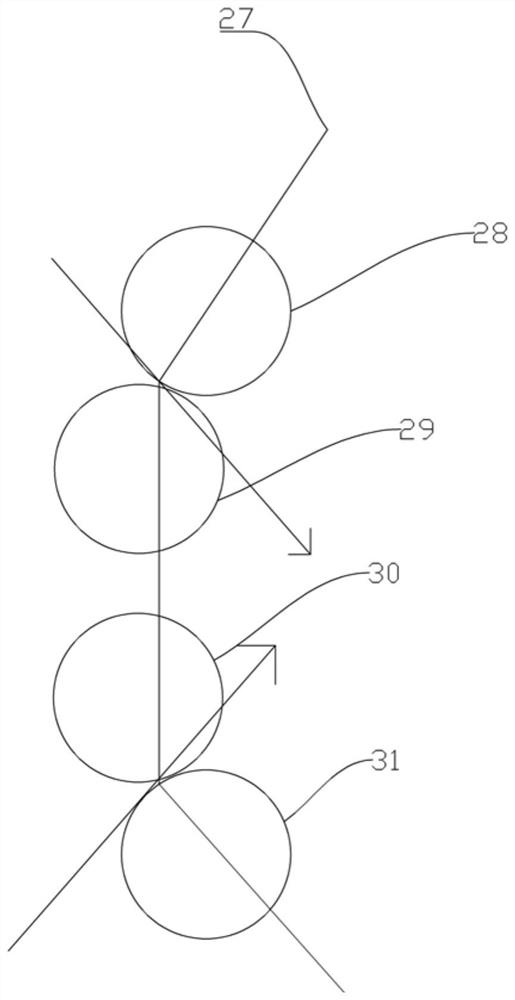

[0052] A plurality of first-stage mixing pipes are arranged on the second-stage mixing pipe, and the first-stage mixing pipes are arranged symmetrically on both sides of the second-stage mixing pipe. A first mixing plate 36 arranged obliquely upwards, a second mixing plate 37 arranged in parallel with the first mixing plate 36 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com