Front box liquid level control system and using method thereof

A technology of liquid level control and front box, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve problems such as misjudgment, inconvenient liquid level measurement, inaccurate measurement value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

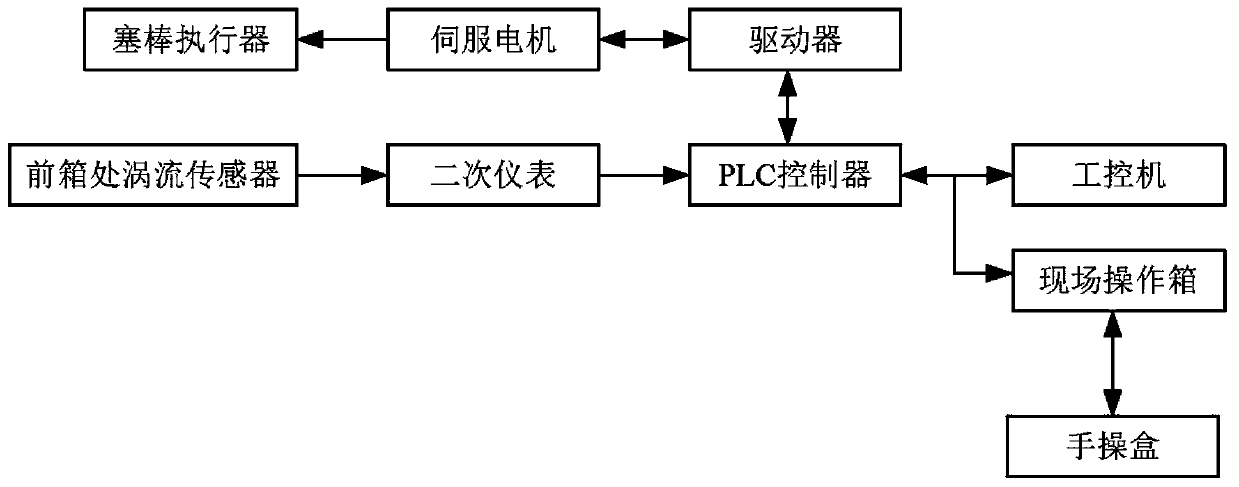

[0025] Such as figure 1 As shown, the present invention provides a technical solution: a front box liquid level control system includes a manual box, a field operation box, an industrial computer, a PLC controller, a secondary instrument, an eddy current sensor at the front box, a driver, a servo motor and stopper rod actuator; the hand-operated box is connected with the field operation box through wires; the field operation box and industrial computer are connected with the PLC controller through wires; the secondary instrument is respectively connected with the PLC controller through wires It is connected with the eddy current sensor at the front box; the driver is connected with the PLC controller through wires; the servo motor is connected with the driver through wires; the stopper rod actuator is connected with the servo motor.

Embodiment 2

[0027] The method for using the front tank liquid level control system includes the following steps:

[0028] Step 1: liquid level detection;

[0029] Step 2: Signal feedback;

[0030] Step 3: Logic operation;

[0031] Step 4: Opening control.

[0032] Said step 1: liquid level detection, the eddy current sensor at the front box detects the liquid level of the aluminum water in the front box, and the eddy current sensor generates an electromagnetic signal to generate an eddy current on the surface of the aluminum water, and this eddy current is generated on the coil of the eddy current sensor at the front box Induction signal, the strength of the signal varies with the distance from the surface of the aluminum water to the bottom of the eddy current sensor at the front box.

[0033] Said step 2: signal feedback, the induction signal of the eddy current sensor at the front box is transmitted to the secondary instrument through the cable, and the liquid level height and vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com