Bogie of unit braking device

A braking device and bogie technology, applied in bogies, railway braking systems, transportation and packaging, etc., can solve the problems of limited vehicle design space, low transmission efficiency, eccentric brake shoe wear, etc., to eliminate brake shoe eccentricity. Grinding phenomenon, improving braking efficiency, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

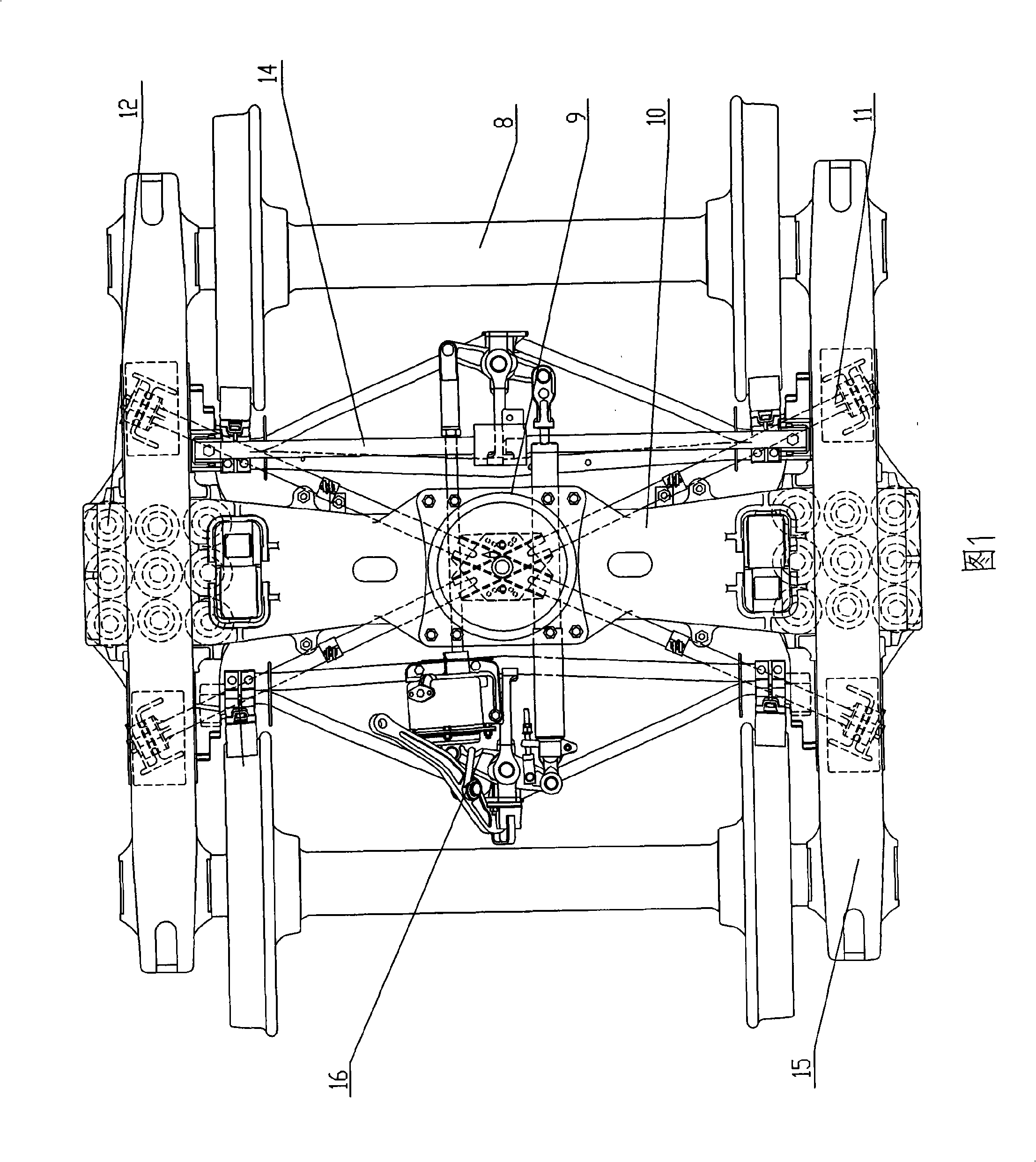

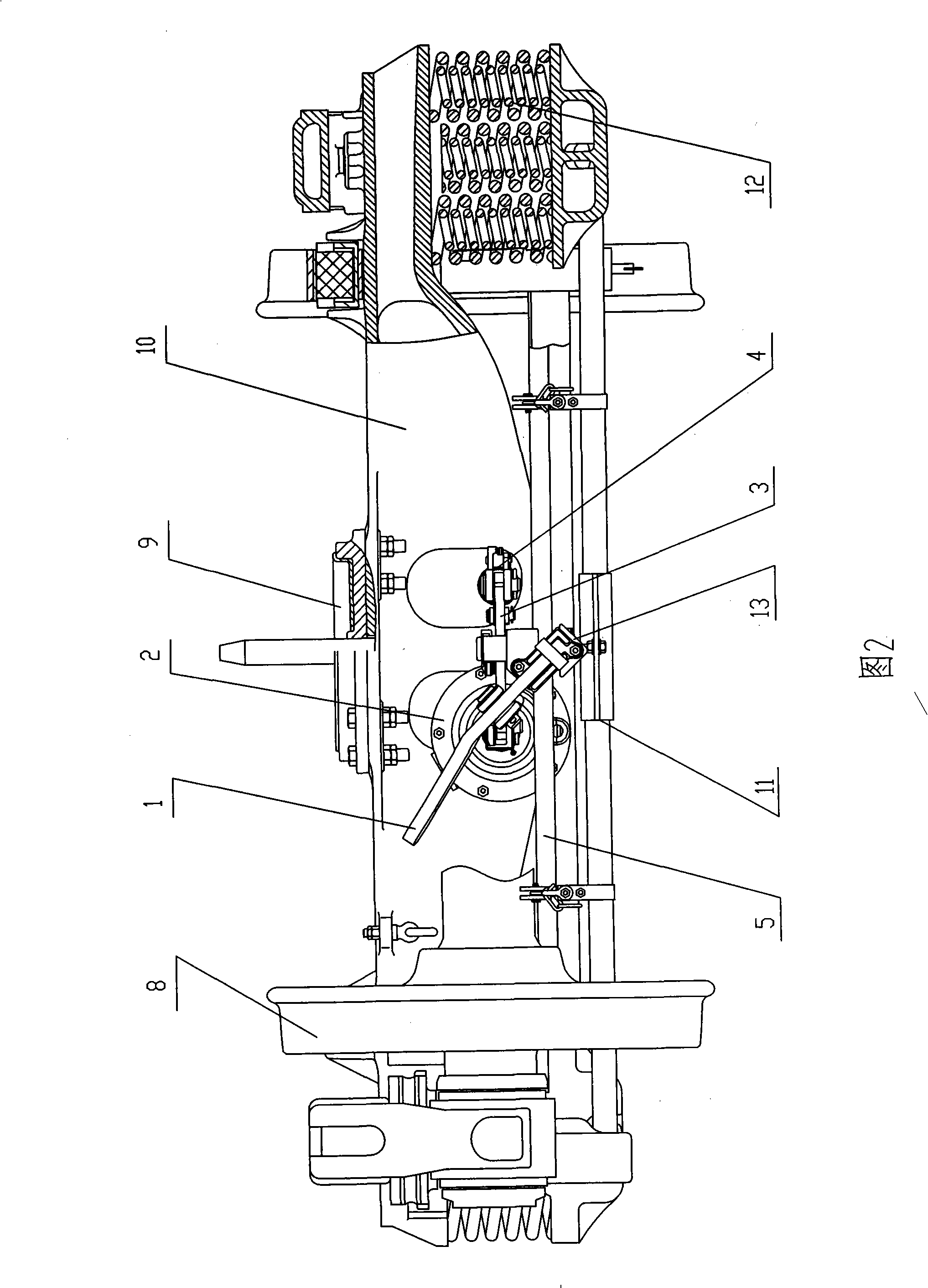

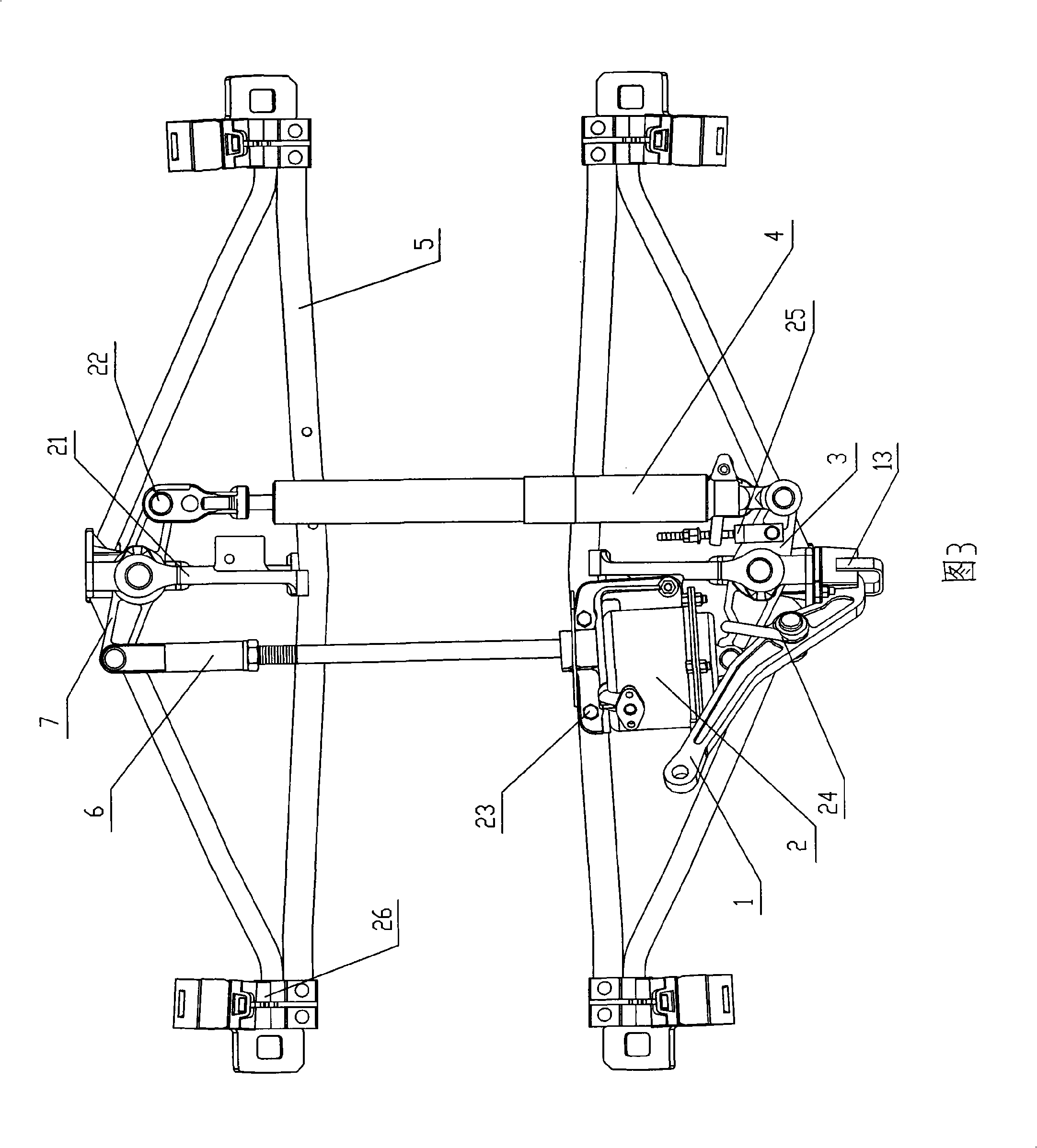

[0011] Unit braking device bogie, including bolster, side frame, wheel set, cross bar, cross beam, lower center plate, the two ends of the bolster are installed in the side beam, and the two sets of wheel sets are installed in the side frame. The two ends of the cross bar are installed in the side frame, the two ends of the cross beam are installed on the side frame, fixed with bolts, and the lower center plate is installed on the bolster. It is characterized in that the unit braking device is composed of a brake beam and a unit brake Cylinder, hand brake lever, anti-off hanger, chain ring hanger, brake lever, fixed pillar, compression brake adjuster, lever, pin, brake cylinder push rod, limiter, the two ends of the brake beam are installed In the sliding groove of the side frame, install the unit brake cylinder on the brake beam, fix it with bolts, install the fixed pillar on the brake beam, and then install the anti-off hanger to fix it on the brake beam, and the hand brake l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com