Bicycle driven by footstock lever and transmitted by rope

A technology of rope drive and bicycle, which is applied in rider drive, chain/belt drive, vehicle parts, etc. It can solve the problems such as difficult to reduce friction of one-way clutch, large friction of reverse flywheel, and easy slipping of drive rope, etc. , to achieve the effect of reducing the tension of the rope, increasing the speed and ensuring the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

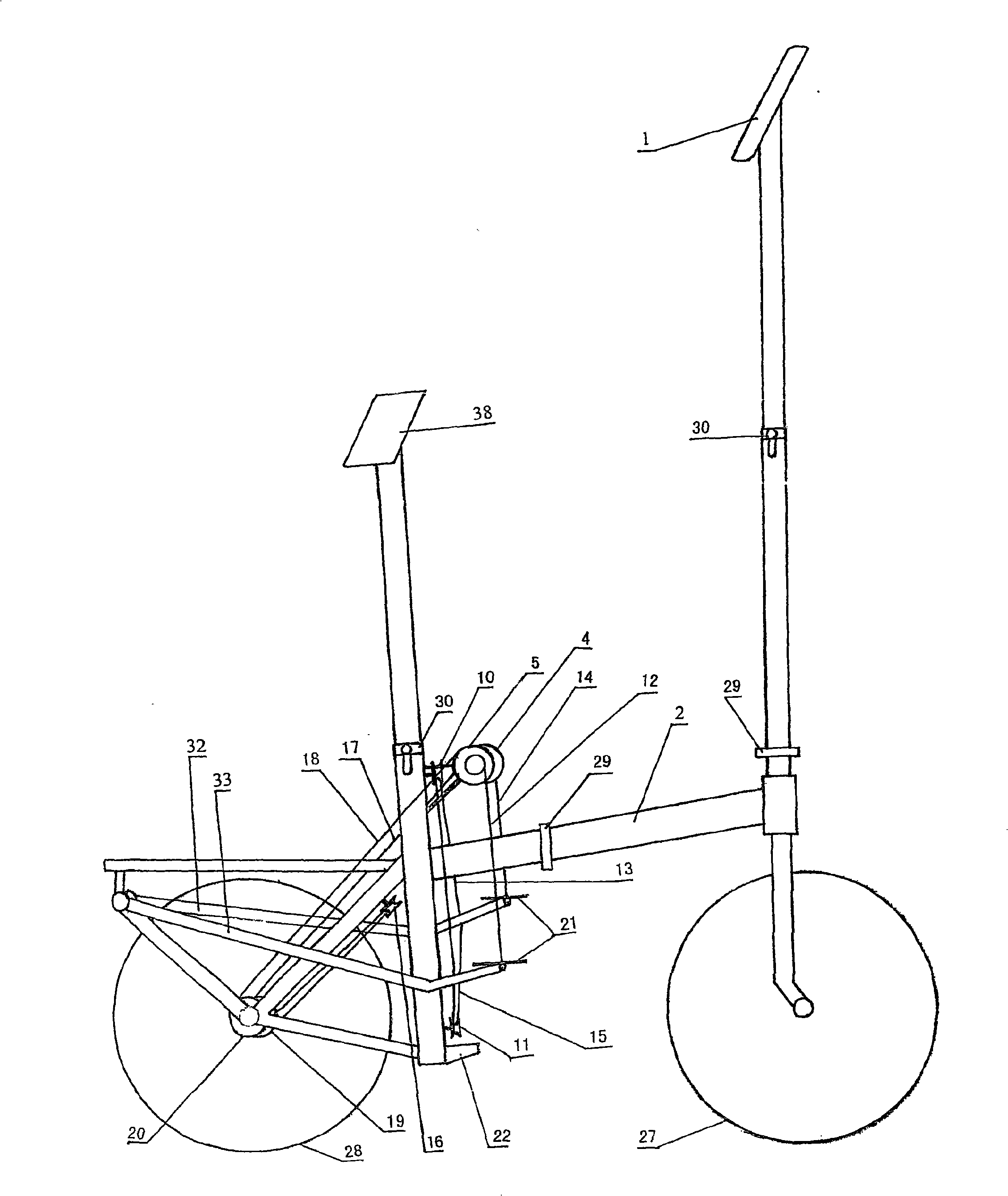

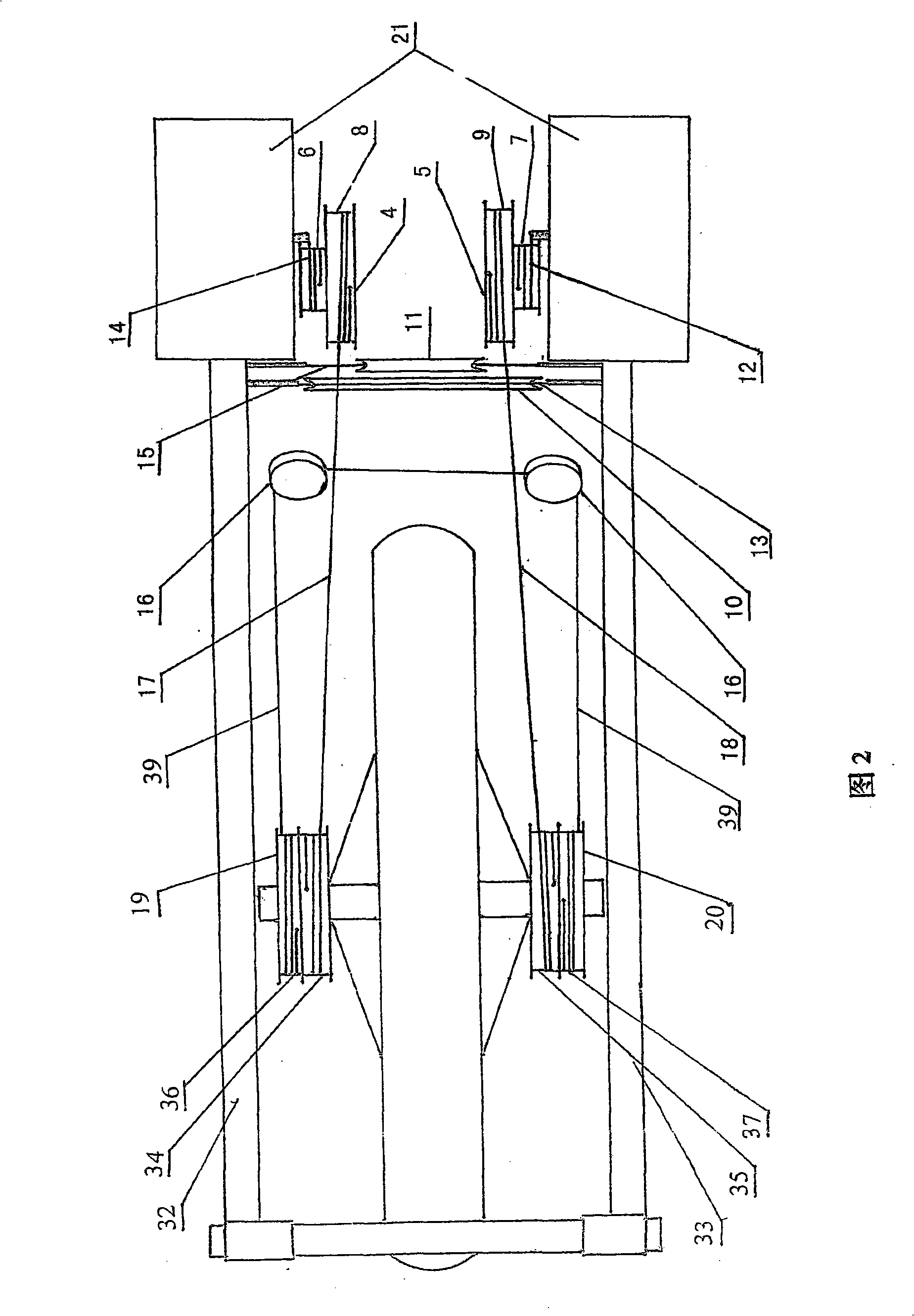

[0011] Such as figure 1 , shown in Fig. 2, the present invention comprises handlebar (1), vehicle frame (2), vehicle seat (38), front and rear wheels (27,28), folding part (29), telescopic part (30), left one-way Clutch (19), right one-way clutch (20), the rear end of left and right step bar (32,33) is respectively hinged with vehicle frame both sides, front end is hinged with pedal (21), simultaneously with left, right respectively. One end of the power stay rope (14,12) is connected, and the left and right power stay ropes are respectively wound in the active rope grooves (6,7) of the left and right drive wheels to fix the other end point after 3-5 turns; One end of the rope (17, 18) is respectively fixed in the driven rope grooves (8, 9) of the left and right drive wheels, and after being wound in the driven rope grooves of the left and right drive wheels (4, 5) for 2-3 turns Pull to the left and right one-way clutch transmission rope grooves (34,35) respectively and fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com