Manual pulse generator

A manual pulse and generator technology, applied in the direction of instruments, control components, mechanical control devices, etc., can solve the problems of shortened mechanical life, unresolved quality problems, and inability to recover, and achieves exquisite and beautiful appearance, long service life, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

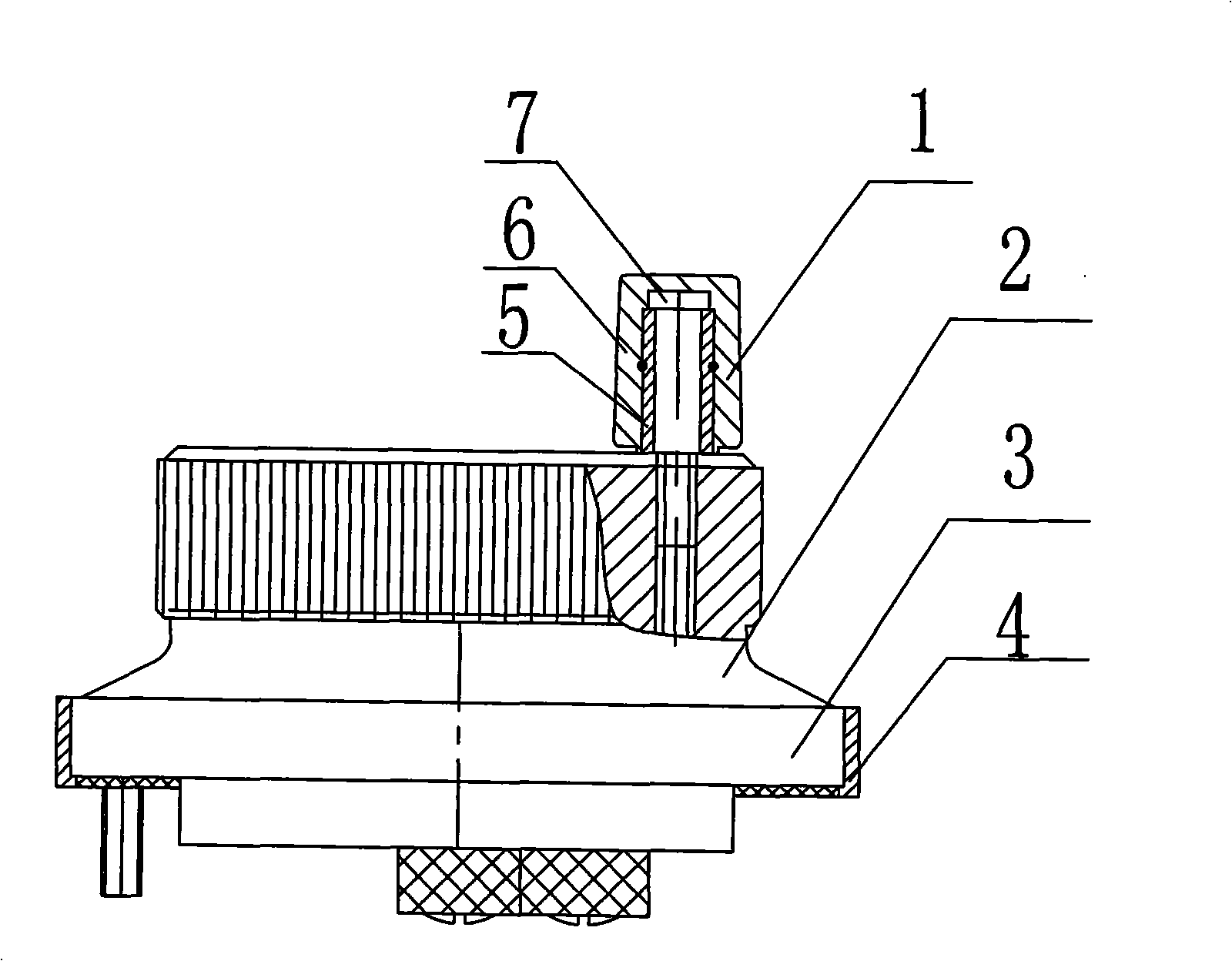

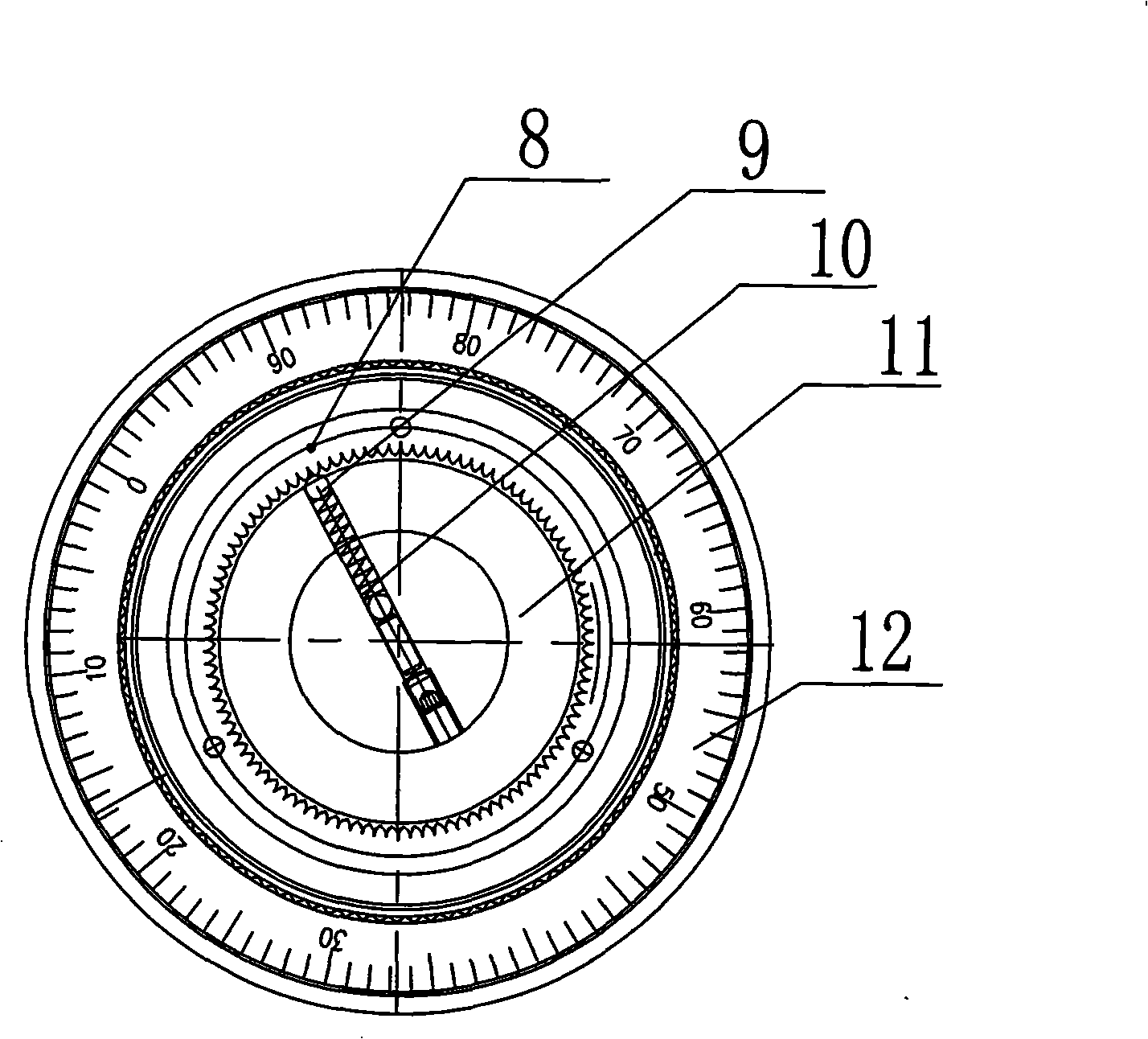

[0010] like figure 1 , figure 2 A manual pulse generator of the best embodiment shown has a hand wheel 2, a hand wheel handle 1, a main body 3, and a main shaft 11. The hand wheel 2 is provided with a dial 12, and the main shaft 11 driven by the hand wheel 2 is interspersed. On the central hole of the main body 3, a grating is fixed at the end of the main shaft 11 away from the hand wheel 2, and a positioning device is provided in the cavity between the hand wheel 2 and the main body 3, and the positioning device includes an inner ring gear 8 fixed on the main body 3, A rotary disc is fixed on the main shaft 11 in the inner ring gear 8, and a radial hole is opened on the rotary disc, and a spring 10 is arranged in the radial hole, and the front end of the spring 10 is provided with a ball 9 embedded in the tooth groove of the inner ring gear 8, The handwheel handle 1 includes a shell 6 with an open end, a fixing screw 7 and a bushing 6, the fixing screw 7 is threaded through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com