Off-axis air-intaking discharging glass tube for large power gas laser

A gas laser and glass tube technology, applied in gas laser parts, laser parts and other directions, can solve the problems of uneven distribution of gain medium flow field and insufficient gas turbulence, and achieve stable and reliable beam quality, symmetrical and uniform beam The effect of uniform distribution of mass and flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

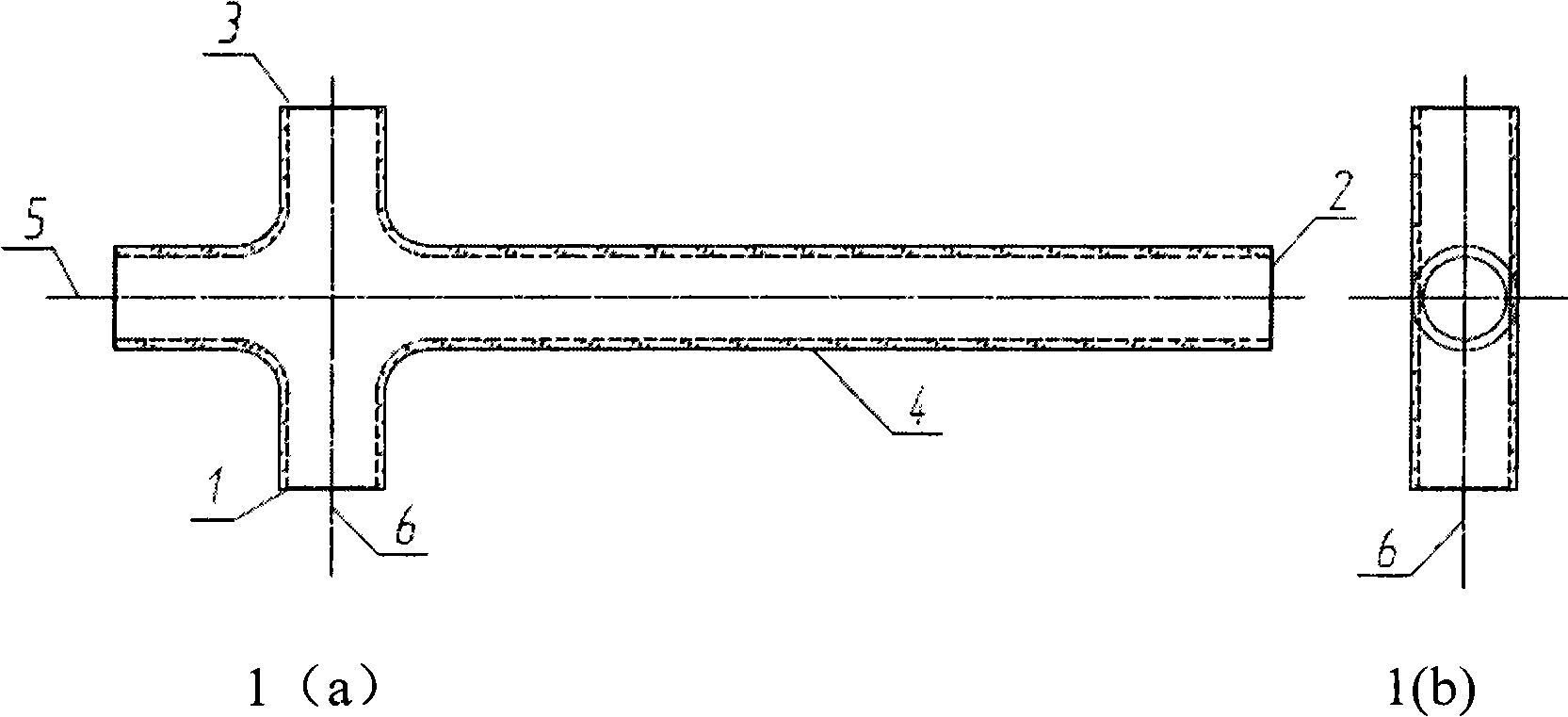

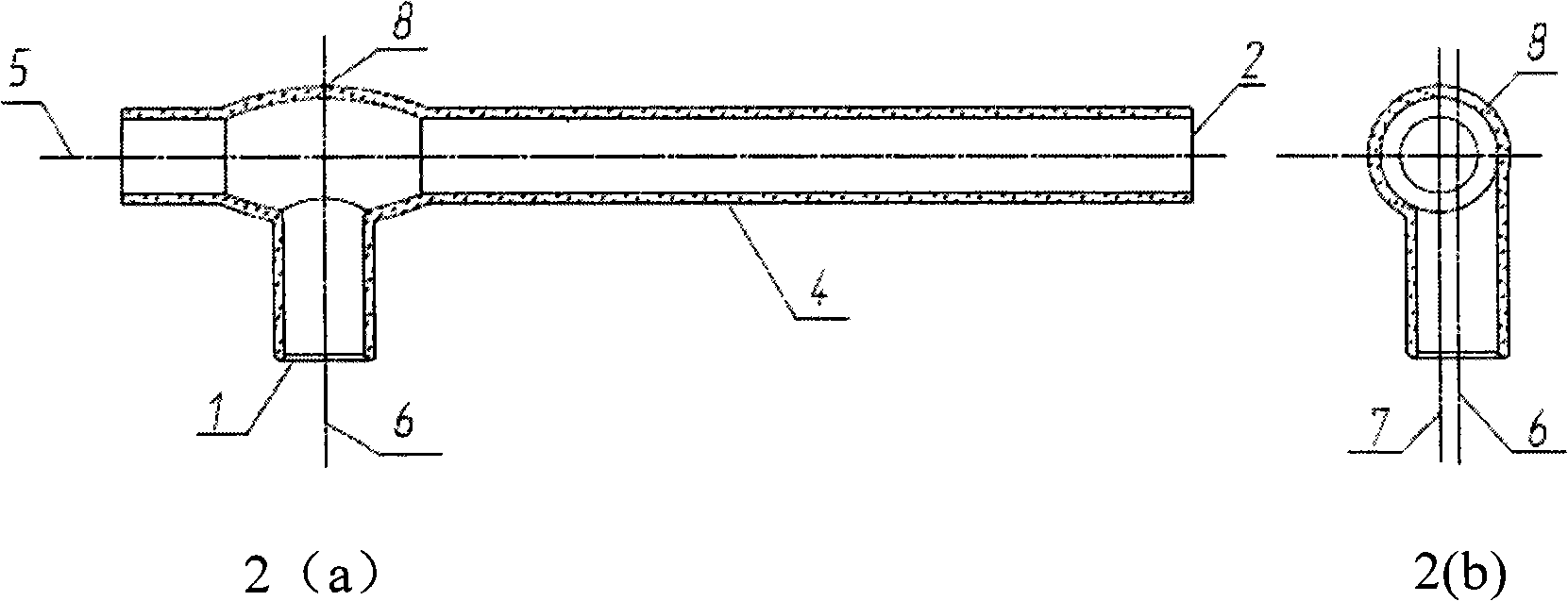

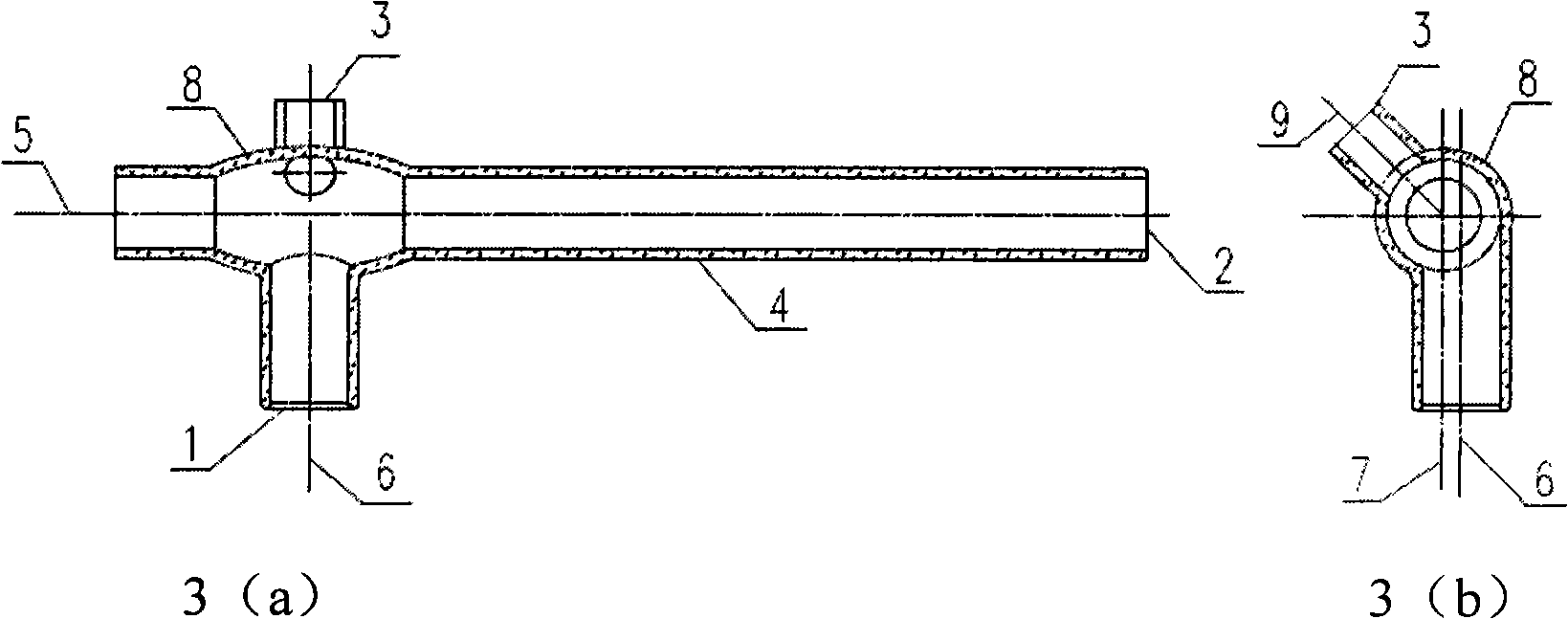

[0012] Such as figure 2 As shown, the structure of the discharge glass tube provided by the present invention is: the vertical air inlet part 1, which is also the installation part of the anode needle; the gas outlet 2, which is connected to the cathode ring installation part outside; the horizontal straight pipe part 4 is the glow discharge area , is also the laser gain oscillation amplification region;

[0013] The connecting part 8 of the horizontal straight pipe part 4 and the vertical air inlet part 1 is "bulge-shaped", that is, the longitudinal length of the connecting part 8 is greater than the outer diameter of the air inlet part 1, and the transverse diameter of the connecting part 8 is larger than that of the horizontal straight pipe part 4. The outer diameter, the horizontal direction of the connecting part 8 is connected with the straight pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com