Composite mold of pressure cooker lid

A composite mold and pressure cooker technology, which is applied in forming tools, manufacturing tools, metal processing, etc., can solve the problems of easy formation of waste products, large production and operation sites, and large energy consumption, so as to save resources and energy, reduce the operation site, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only used as examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

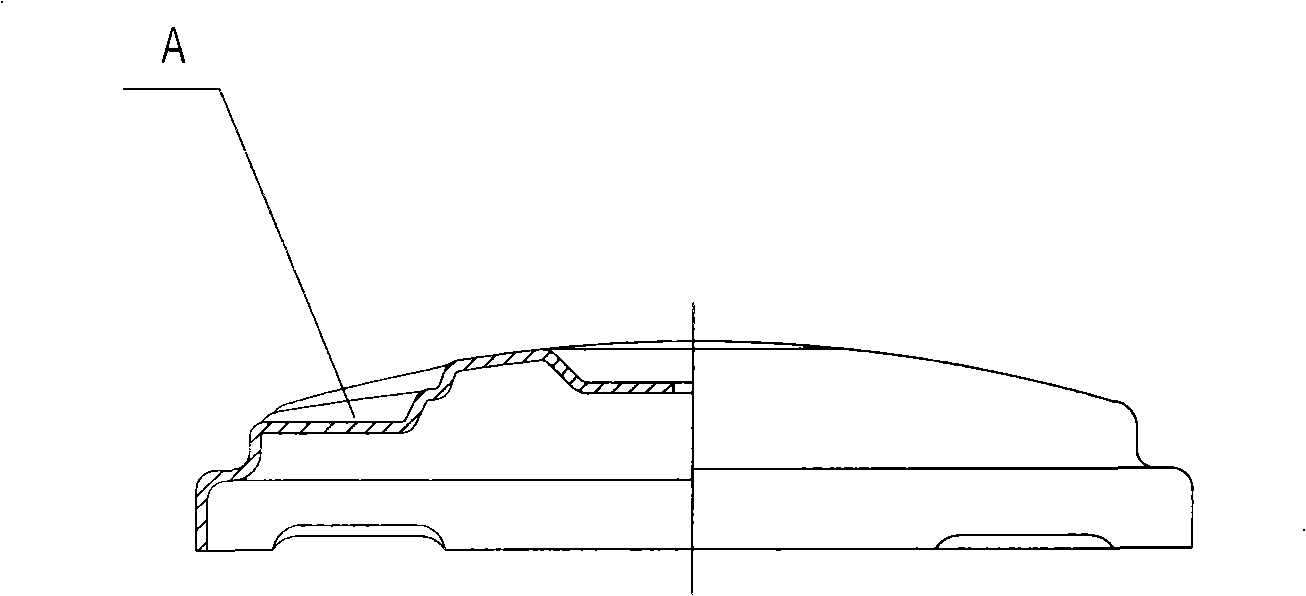

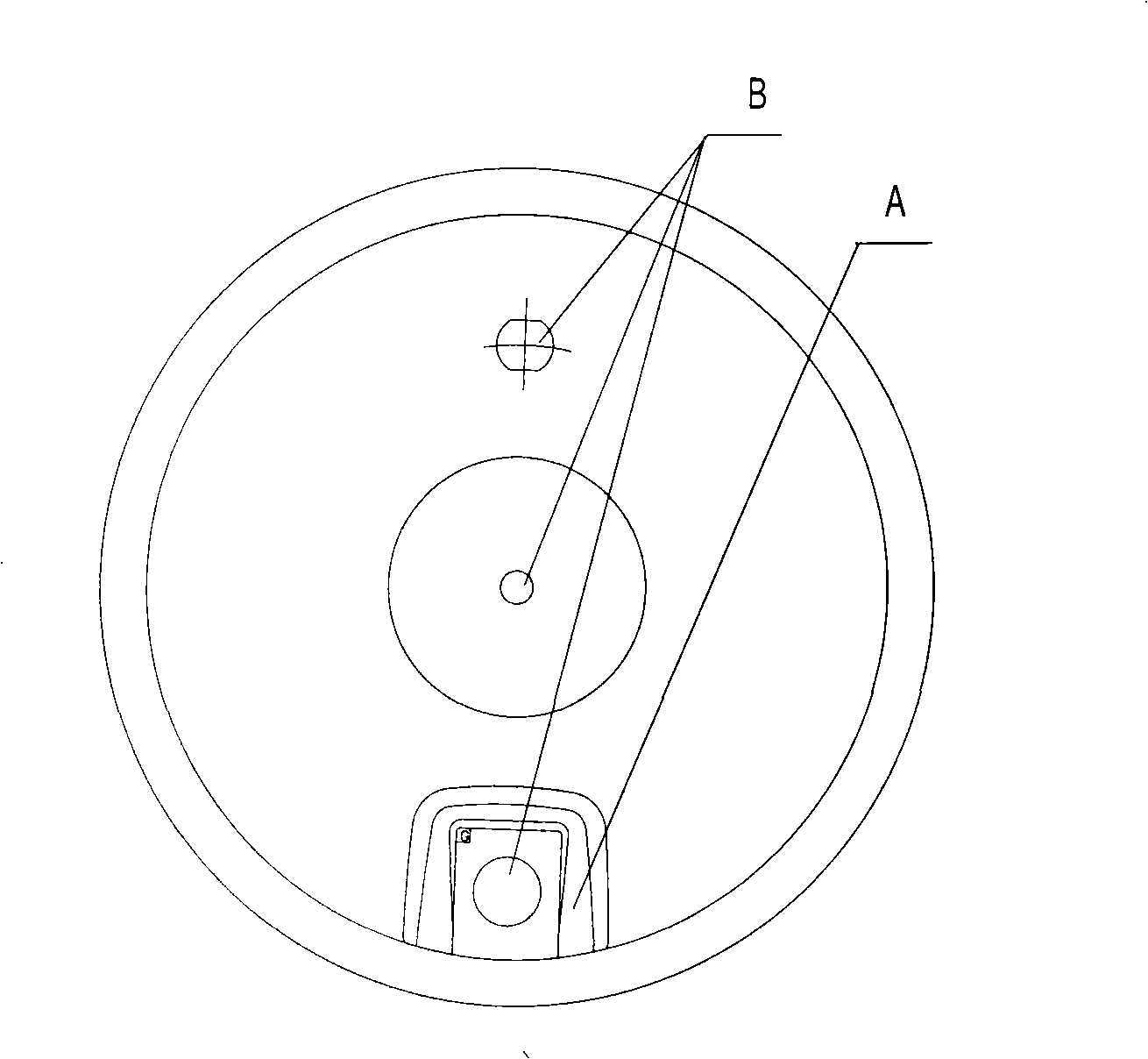

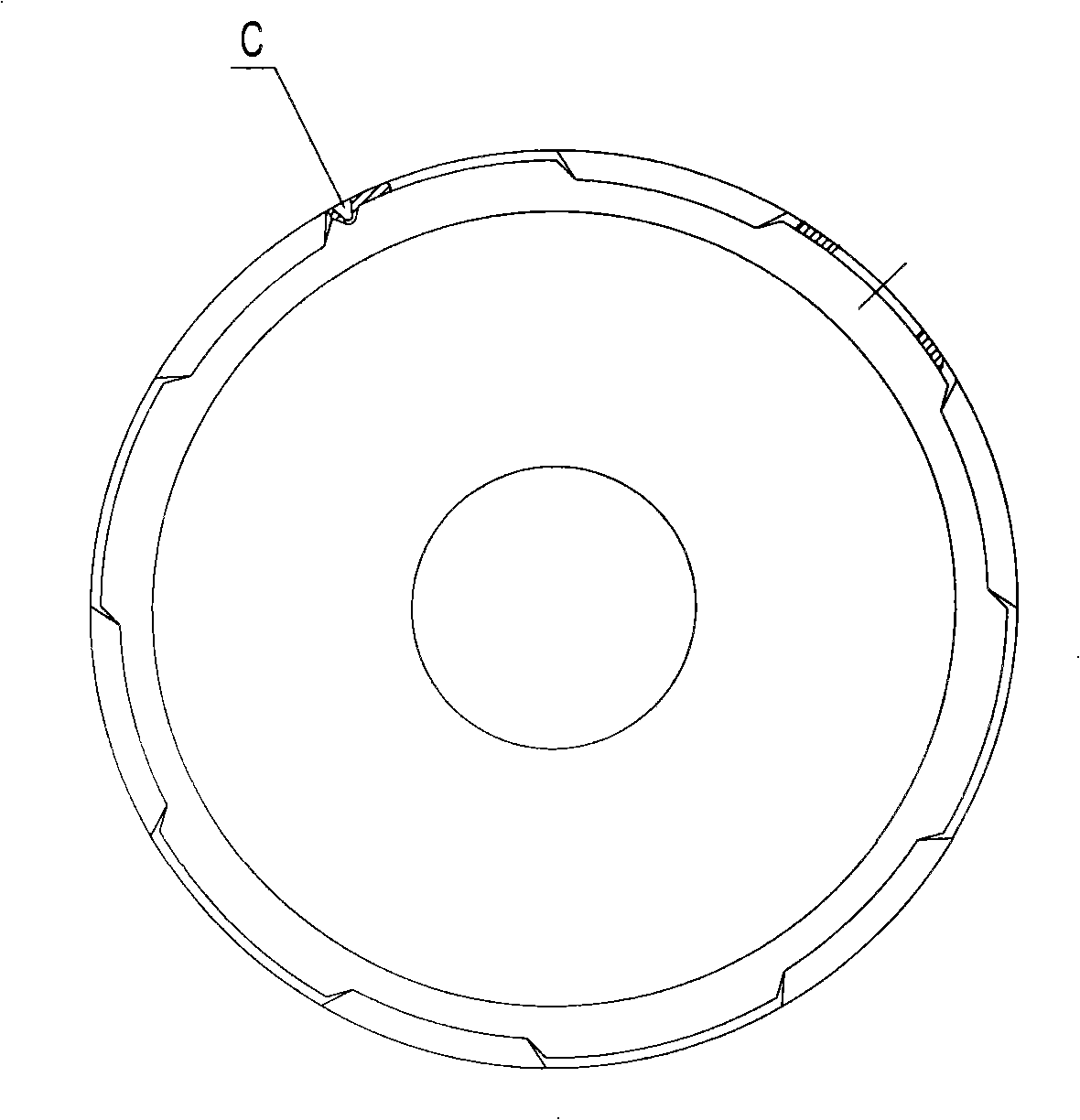

[0028] Referring to the accompanying drawings, it can be seen that the pressure cooker lid composite mold of the present invention comprises an upper template 2 and a lower template 1, and guide pillars 12 are arranged at the two ends between the upper template 2 and the lower template 1, and the guide pillars 12 are fixed on the lower template 1, and the lower template 1 Template 1 is fixed with pot lid die 11, is fixed with punching punch 21 and pressure pit punch 22 on upper template 2, is fixed with the punching die 14 that matches with punching punch 21 and matches with punching punch 21 on the pot lid die 11. The embossing punch 22 matches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com