Synchronous lifting component and synchronous lifting and horizontal moving mechanism

A technology of synchronous lifting and horizontal movement, applied in the direction of lifting devices, mechanical equipment, transmission devices, etc., can solve the problems of lack of stability, high cost, and unsuitable lifting of mask tables, etc., and achieve simple structure, low cost, and reduced occupation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

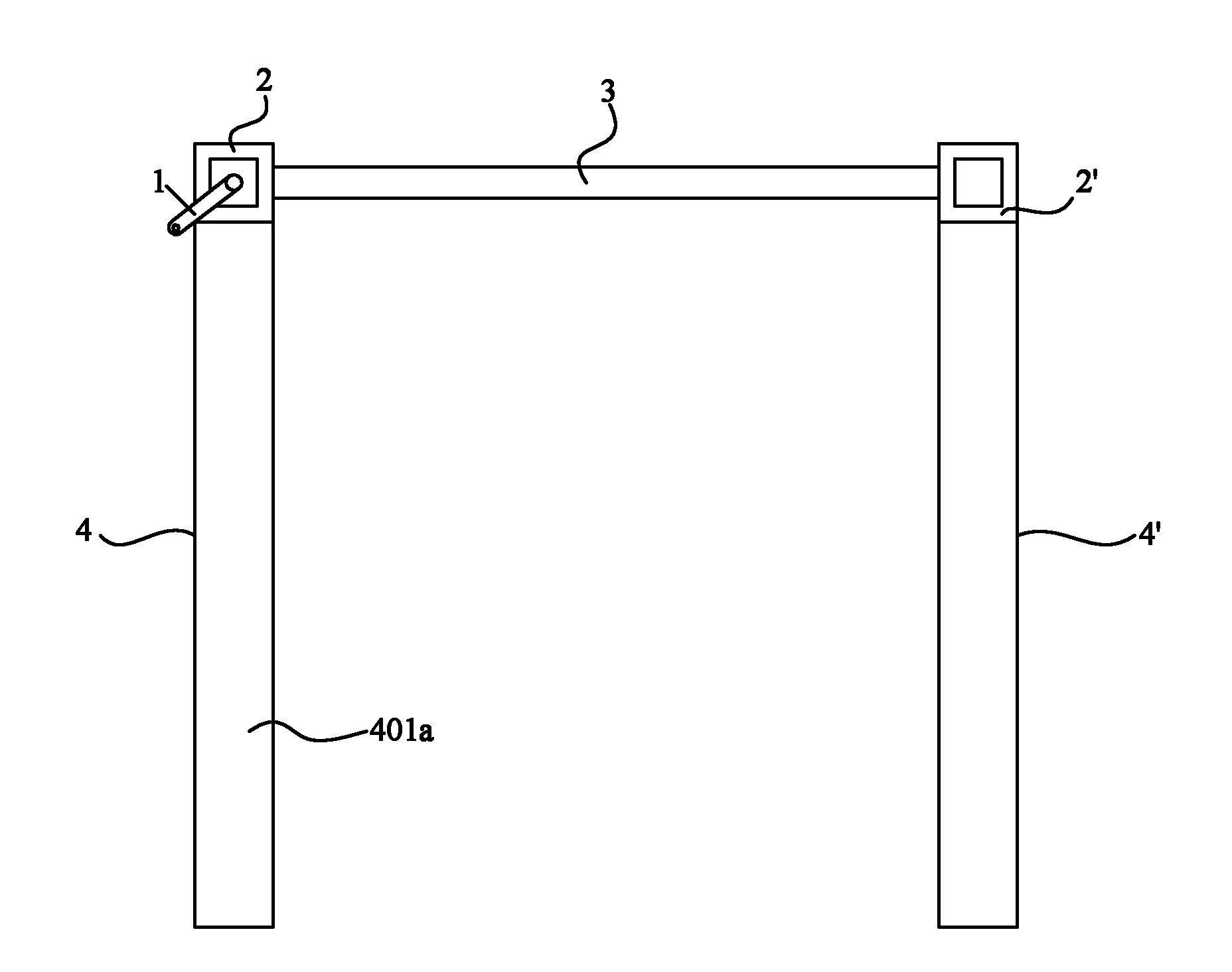

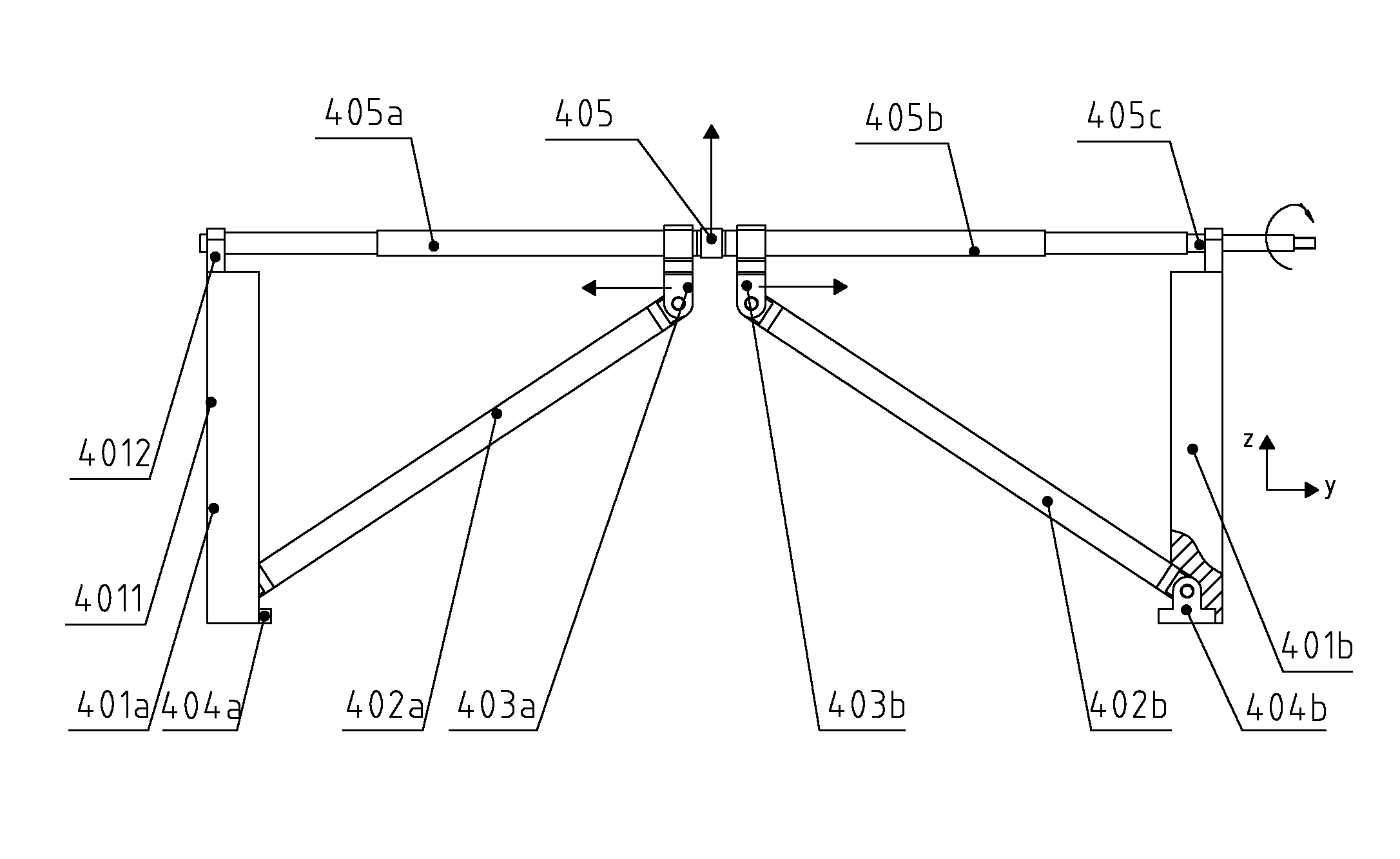

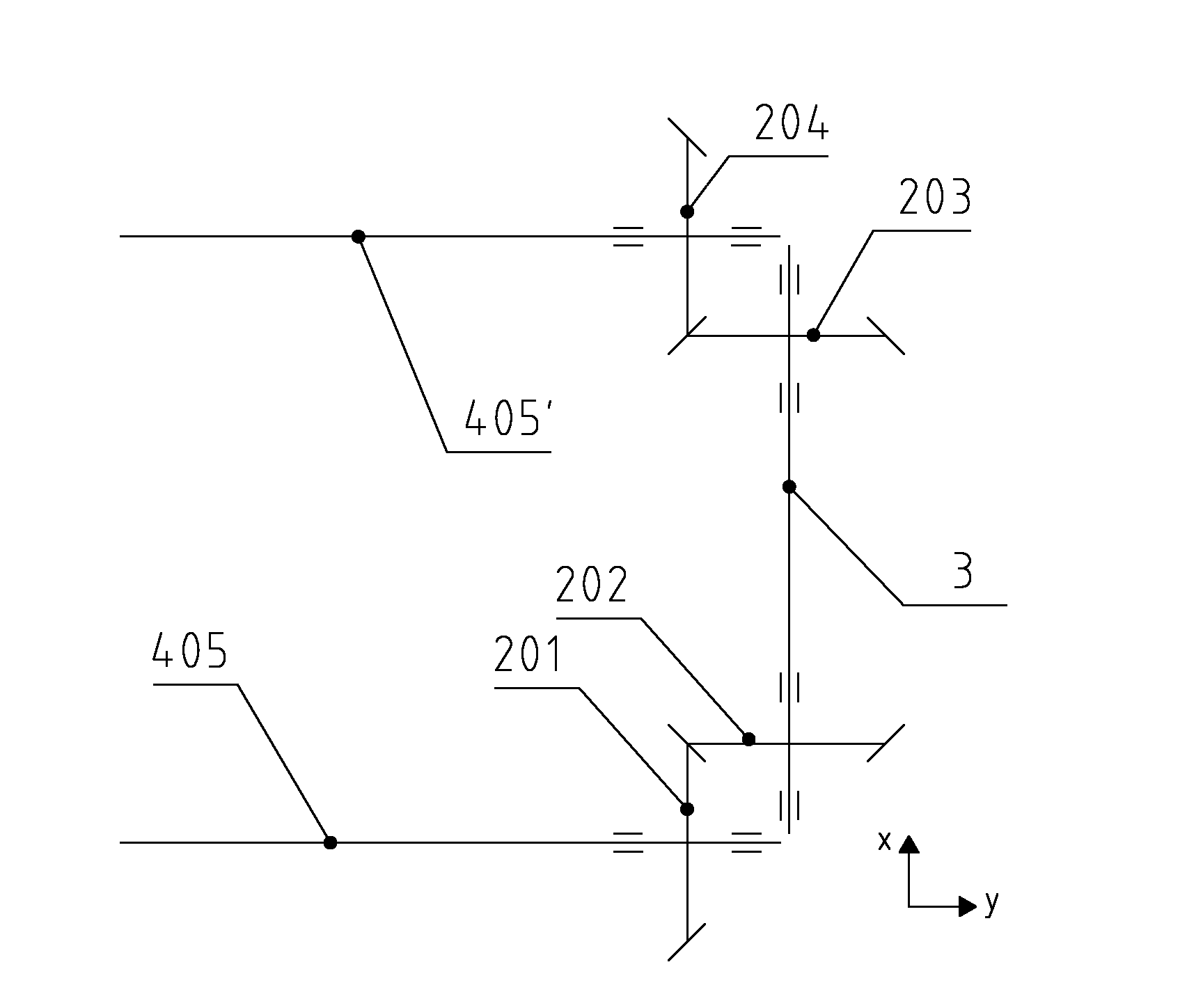

[0022] The following will combine Figure 1 to Figure 6 The synchronous lifting component and the synchronous lifting and horizontal movement mechanism of the present invention are further described in detail.

[0023] A synchronous lifting component for a synchronous lifting and horizontal movement mechanism includes a telescopic lifting unit, a handle, a gear box and a transmission shaft;

[0024] The two ends of the transmission shaft are engaged with the lifting unit through the gear box;

[0025] The handle is arranged at one end of the lifting unit,

[0026] The rotation of the handle stretches or shrinks the lifting unit connected to the handle, and the stretching or shrinking movement of the lifting unit is transmitted to another lifting unit through the transmission unit composed of the gear box and the transmission shaft, realizing two Synchronous raising or lowering of the lifting unit.

[0027] see figure 1 , a synchronous lifting component includes a first lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com