Lifting and hoisting method of vertical equipment

A hoisting method and vertical equipment technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem of single function of the rotating shaft system, and achieve the effect of convenient and flexible operation, flexible operation and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

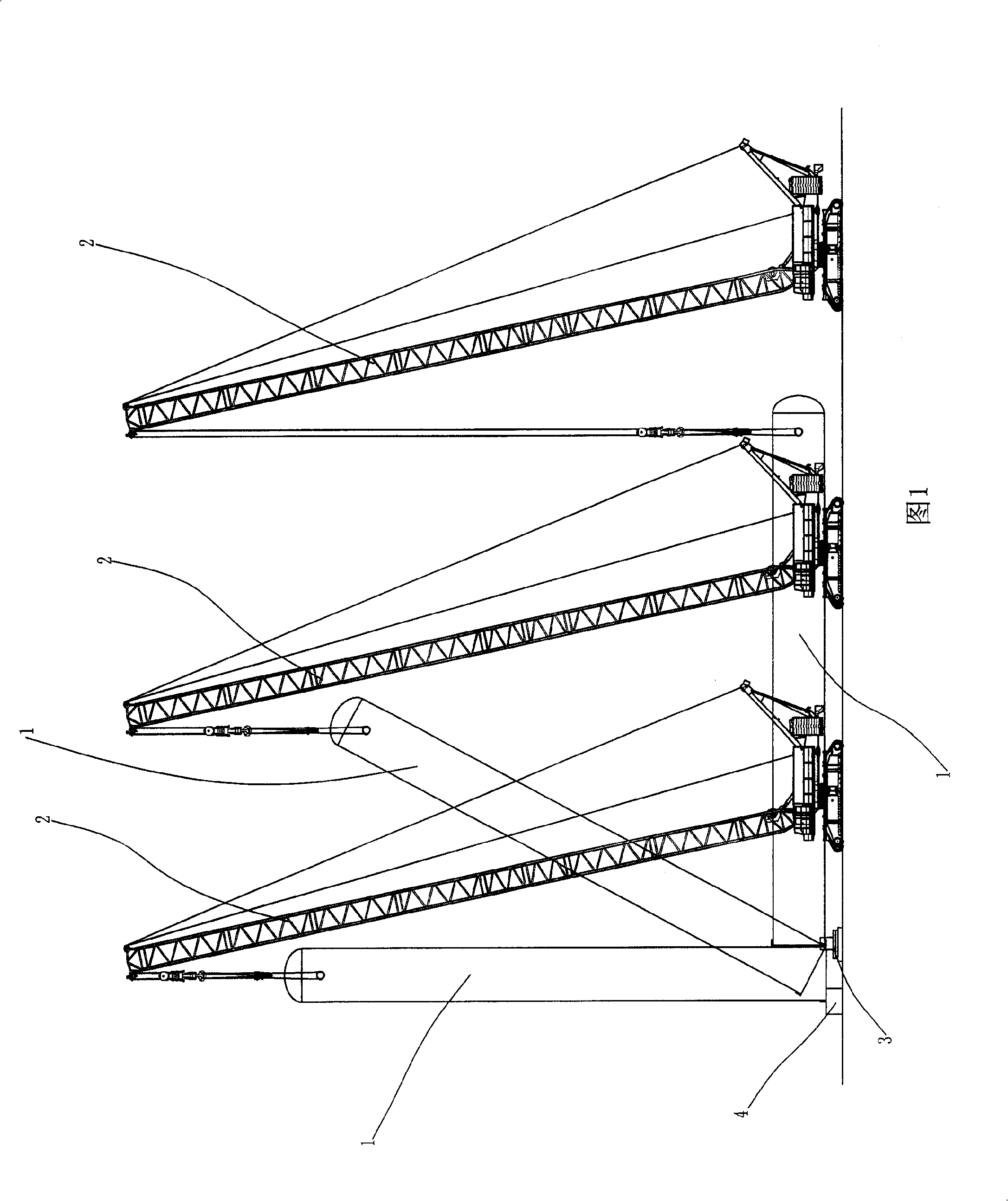

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

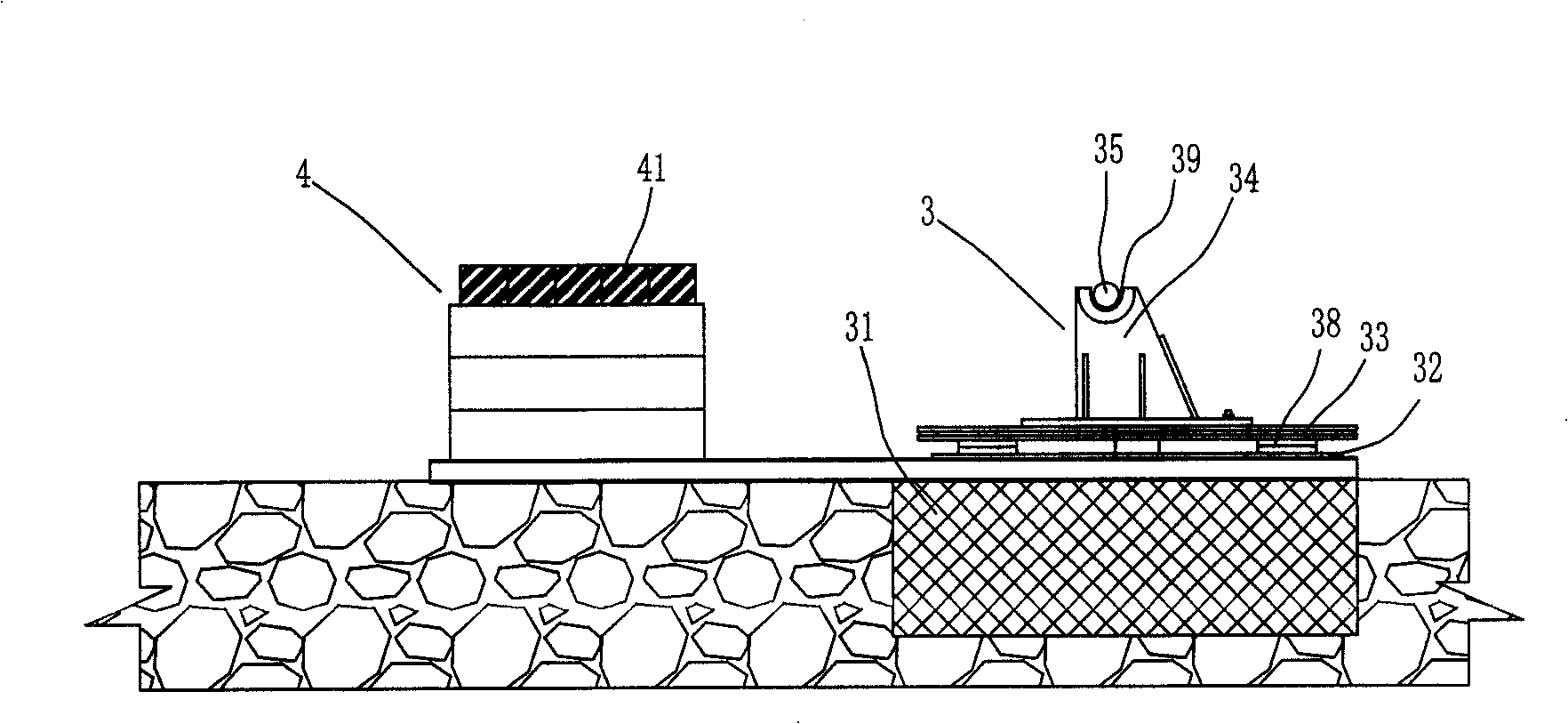

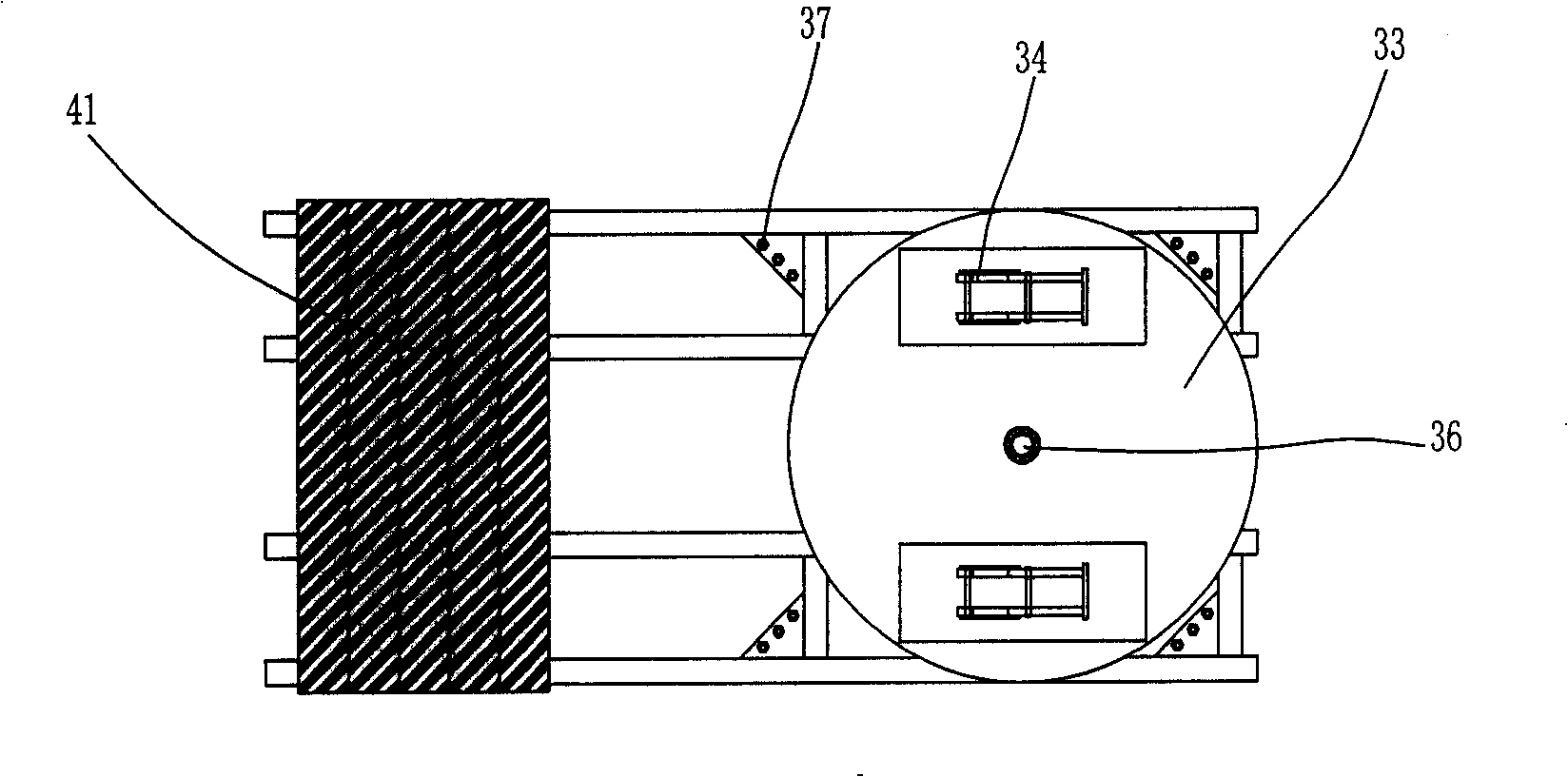

[0035] In the present embodiment, the rotating shaft system 3 and the anti-tilt facility 4 are first set, such as Figure 2 to Figure 3 As shown, the underground foundation 31 is first set up underground. The underground foundation 31 in this embodiment adopts a concrete cap, and the chassis 32 is fixed on the underground foundation 31 by bolts 37 . The turntable 38 is circular and includes an upper turntable and a lower turntable, the lower turntable is fixed on the chassis 32, the lower turntable is fixed on the carrier plate 33 above it, and the upper turntable and the lower turntable are formed by bearing connection A matching structure that can rotate around the vertical axis of rotation 36. Two horizontal shaft bearings 34 are fixedly installed on the bearing plate 33, and a shaft hole 39 is formed on the top of the horizontal shaft bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com