Guide wheel for hoisting endless chain calabash

A lifting ring and guide wheel technology, applied in the field of guide wheels, can solve problems such as potential safety hazards, consumption of steel resources, troublesome assembly operations, etc., and achieve the effects of avoiding pollution, saving steel resources, and reliable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

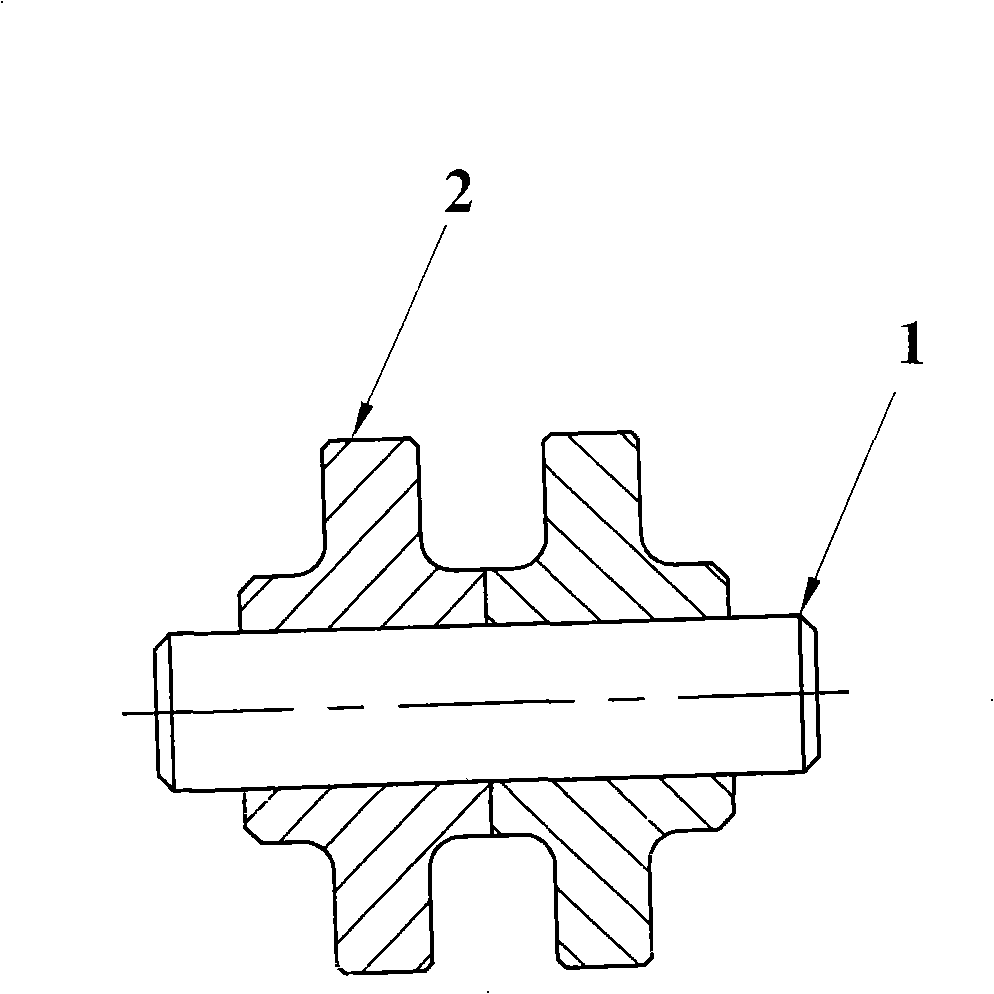

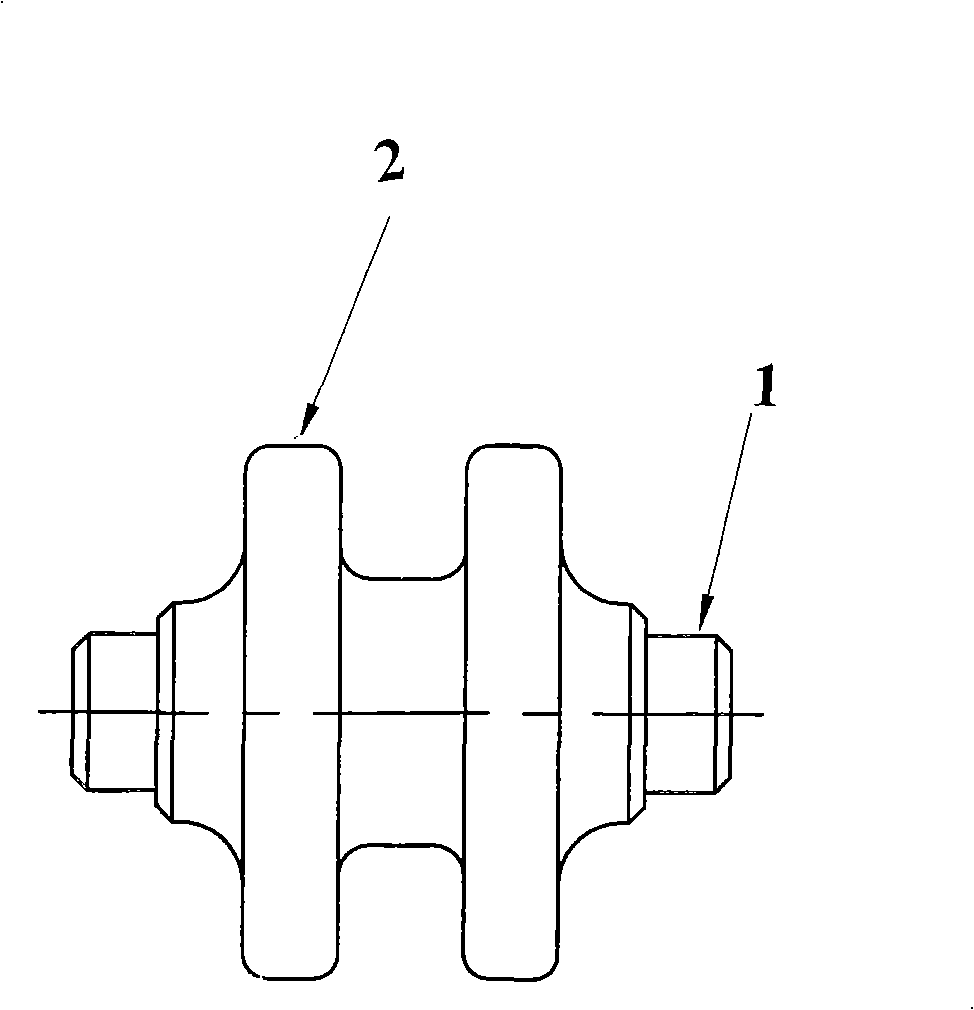

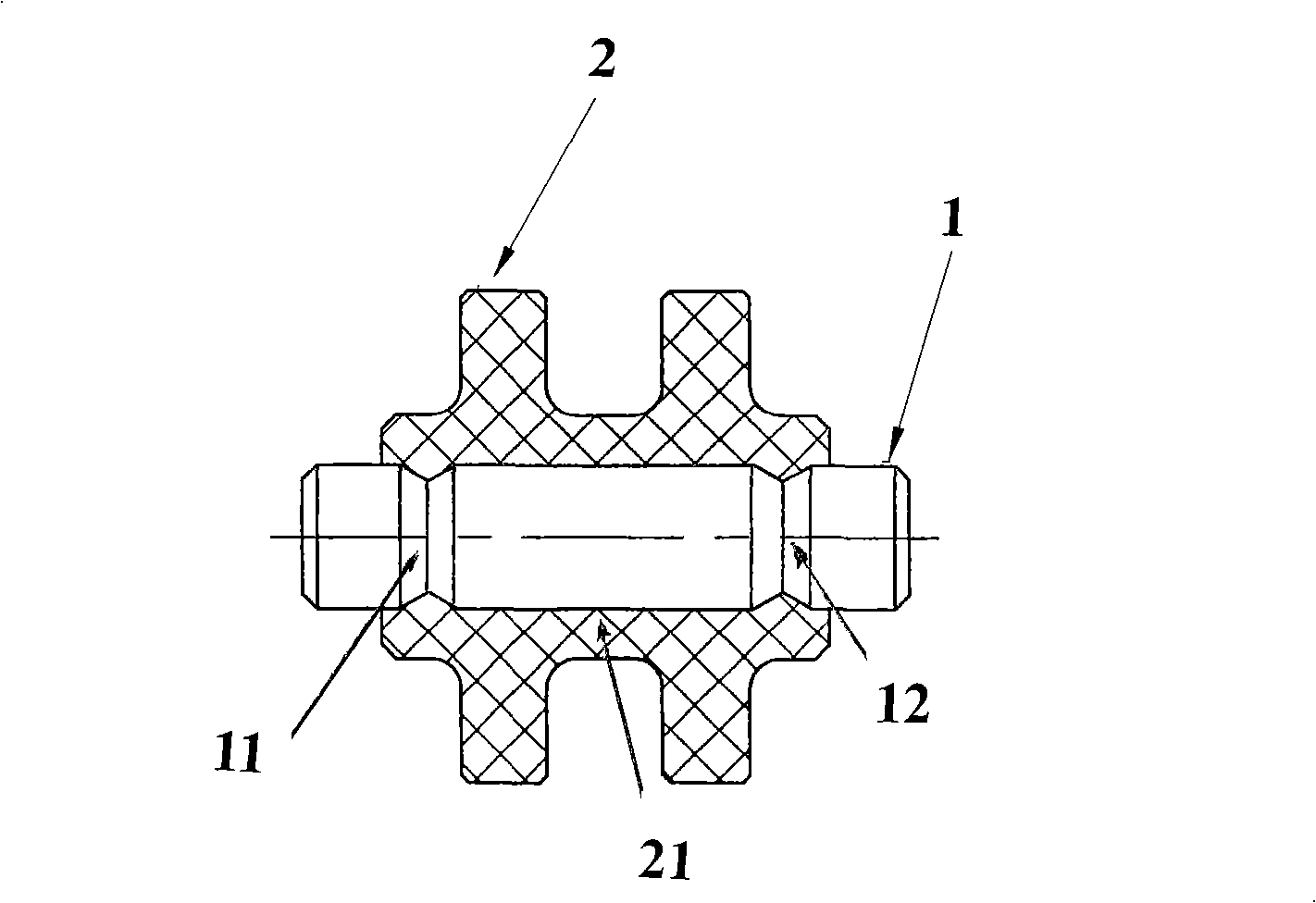

[0012] see image 3 , the material is a mandrel 1 made of metal such as steel, a first groove 11 is formed at one end of the mandrel 1, which is the left end of the position shown in the figure, and a first groove 11 is formed at the other end of the mandrel 1, which is the position shown in the figure A second groove 12 is formed at the right end of the same. The first and second grooves 11, 12 are V-shaped grooves. The rim 2 made of phenolic plastic is combined on the mandrel 1 by a mold in a pressing manner, and The hub 21 of the rim 2 is wedged into the first and second grooves 11 and 12 at the same time and reliably combined with the mandrel 1, so that the two will not be separated and have safety. Adopting phenolic plastic as the material of the wheel rim 2 has lightness and can save steel resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com