Condensed gas flow quantity measuring systems

A measurement system and air flow technology, applied in volume flow measurement device, fluid velocity measurement, measurement, etc., can solve problems such as large oil-water density difference, large gas-oil ratio, inaccurate determination of water content, etc., to ensure accuracy, Avoid the effect of water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

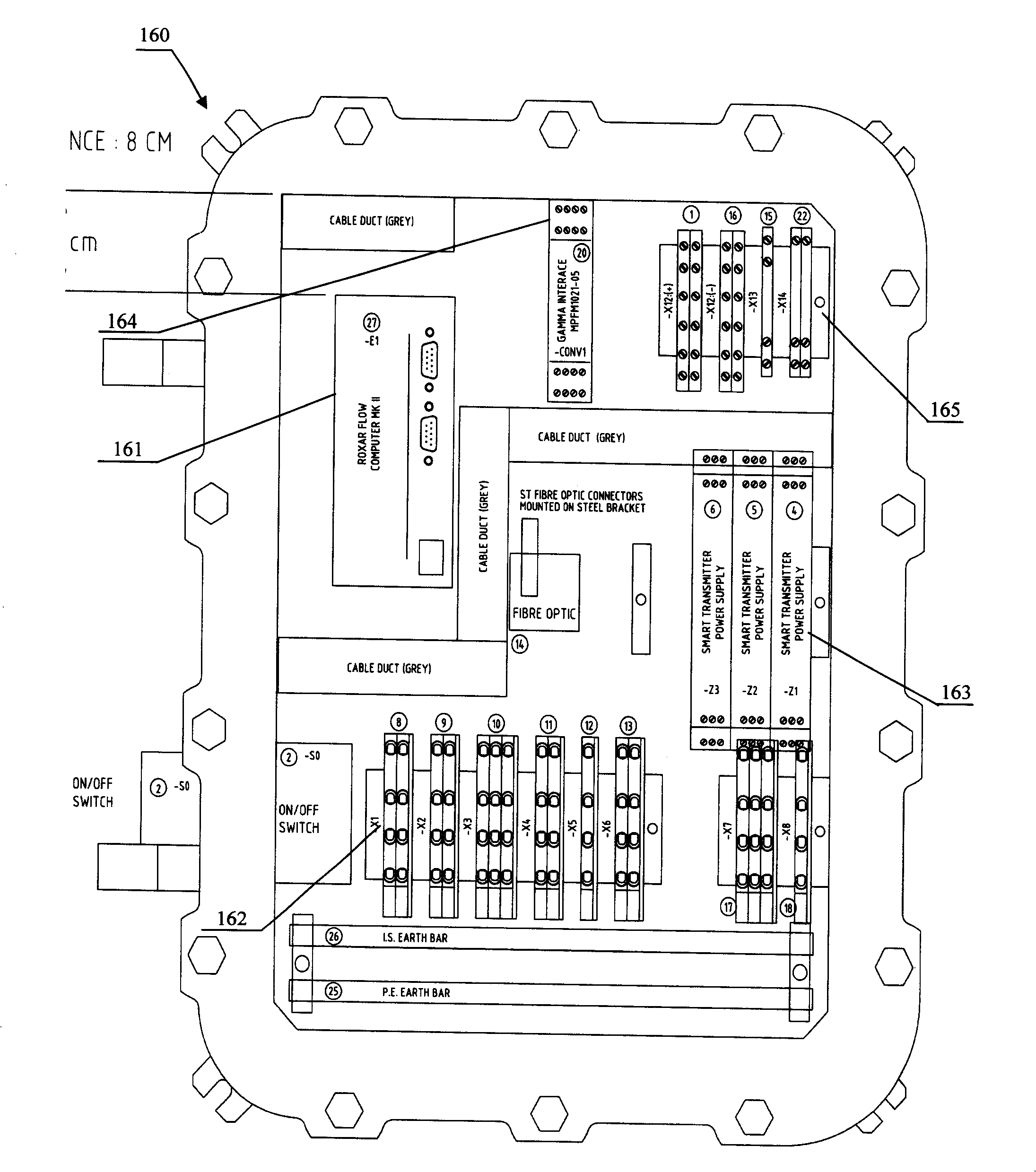

Image

Examples

Embodiment Construction

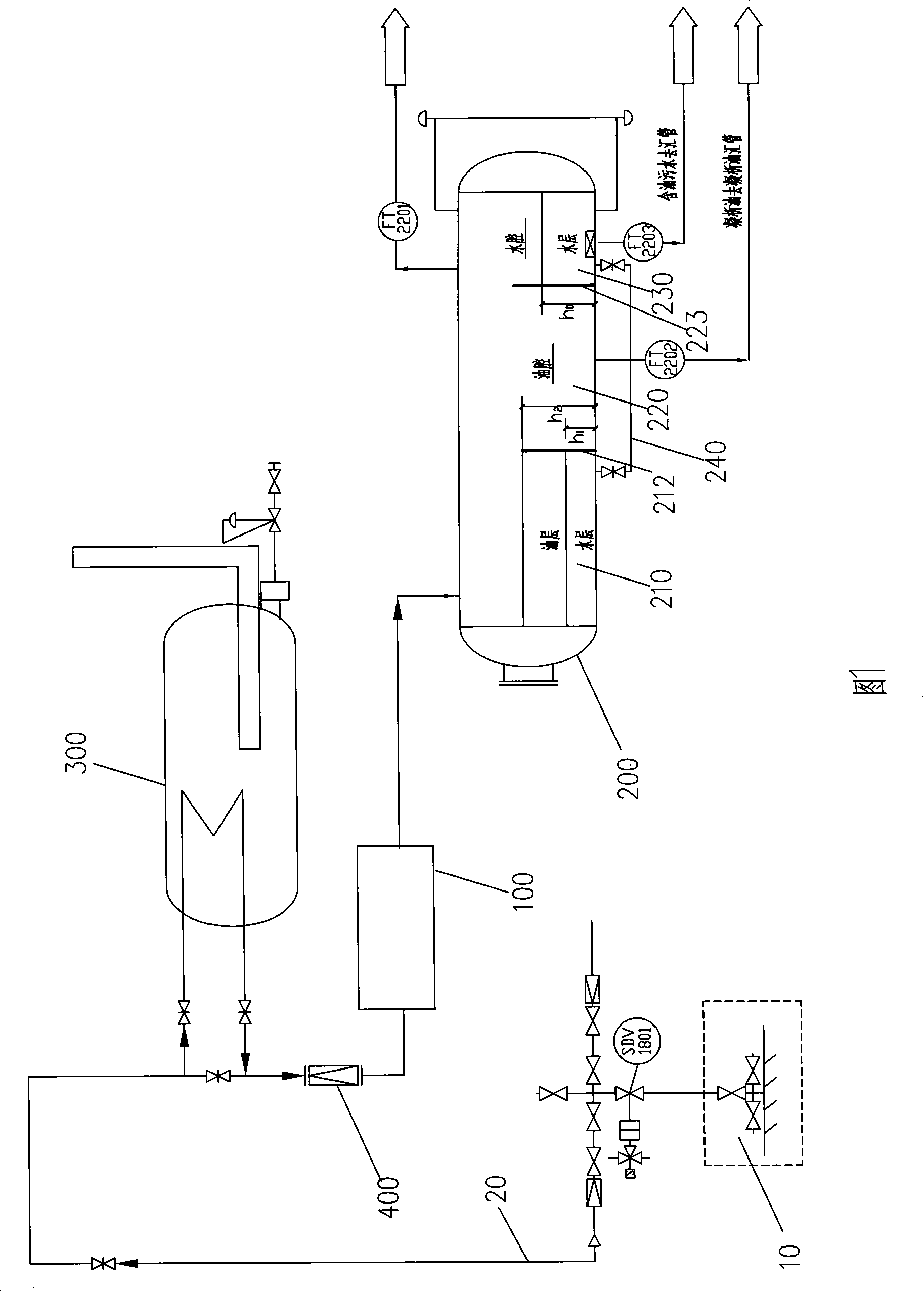

[0025] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation, structure, features and characteristics of the condensate gas flow measurement system proposed according to the present invention with reference to the accompanying drawings and preferred embodiments. Its effect is described in detail as follows.

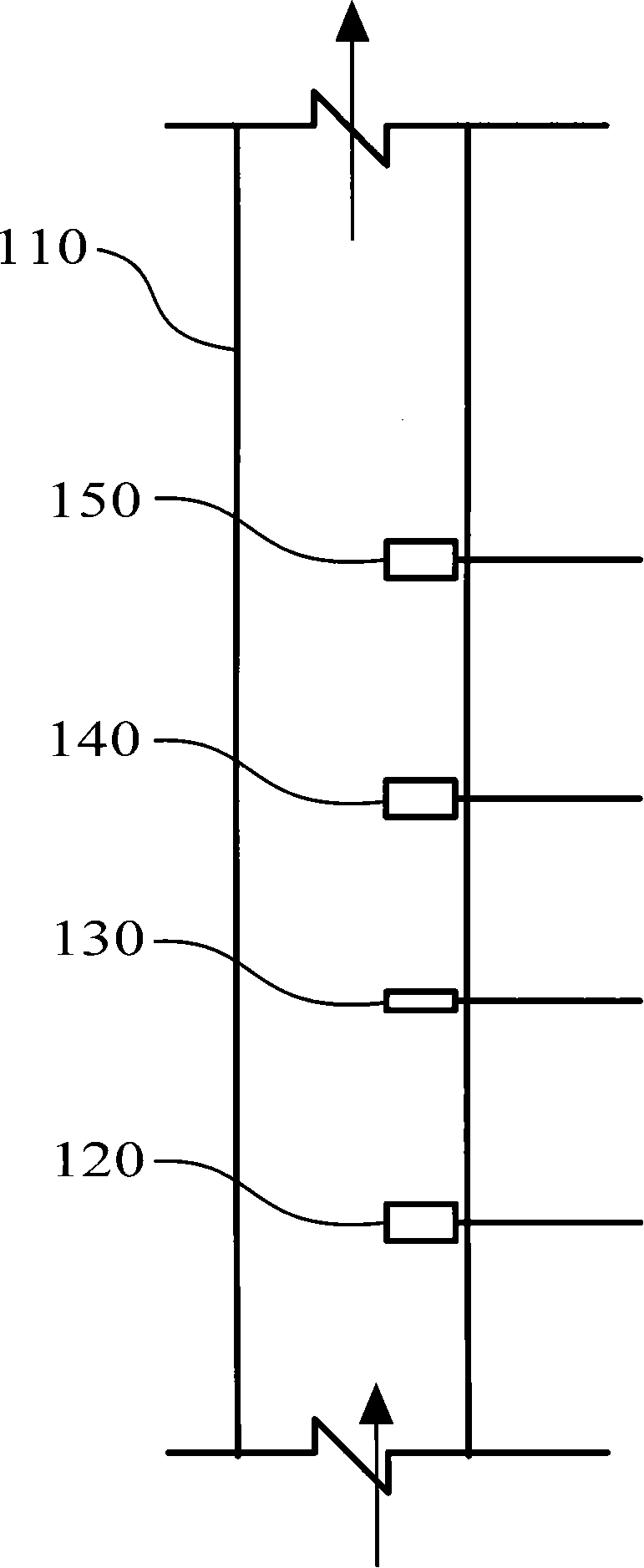

[0026] see figure 1 Shown is a schematic flow chart of an embodiment of the condensate gas flow measurement system of the present invention. The condensate gas flow measurement system is used to measure the flow rate of oil, gas and water in a single well, and includes: a condensate gas production well 10 (which is the prior art and will not be repeated); a gas collection pipeline 20 for conveying condensate gas production The oil-gas-water mixture produced from the well is sequentially provided on the gas gathering pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com