Explosion-proof buffering pressure-storing valve

A pressure storage chamber and valve body technology, applied in the direction of engine components, cylinders, cylinder heads, etc., can solve the problems of damage to the stability and reliability of the engine, deterioration of the combustion process, failure to improve power and economy, etc., to achieve power Good performance in terms of sex and economy, emission performance, improved performance, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

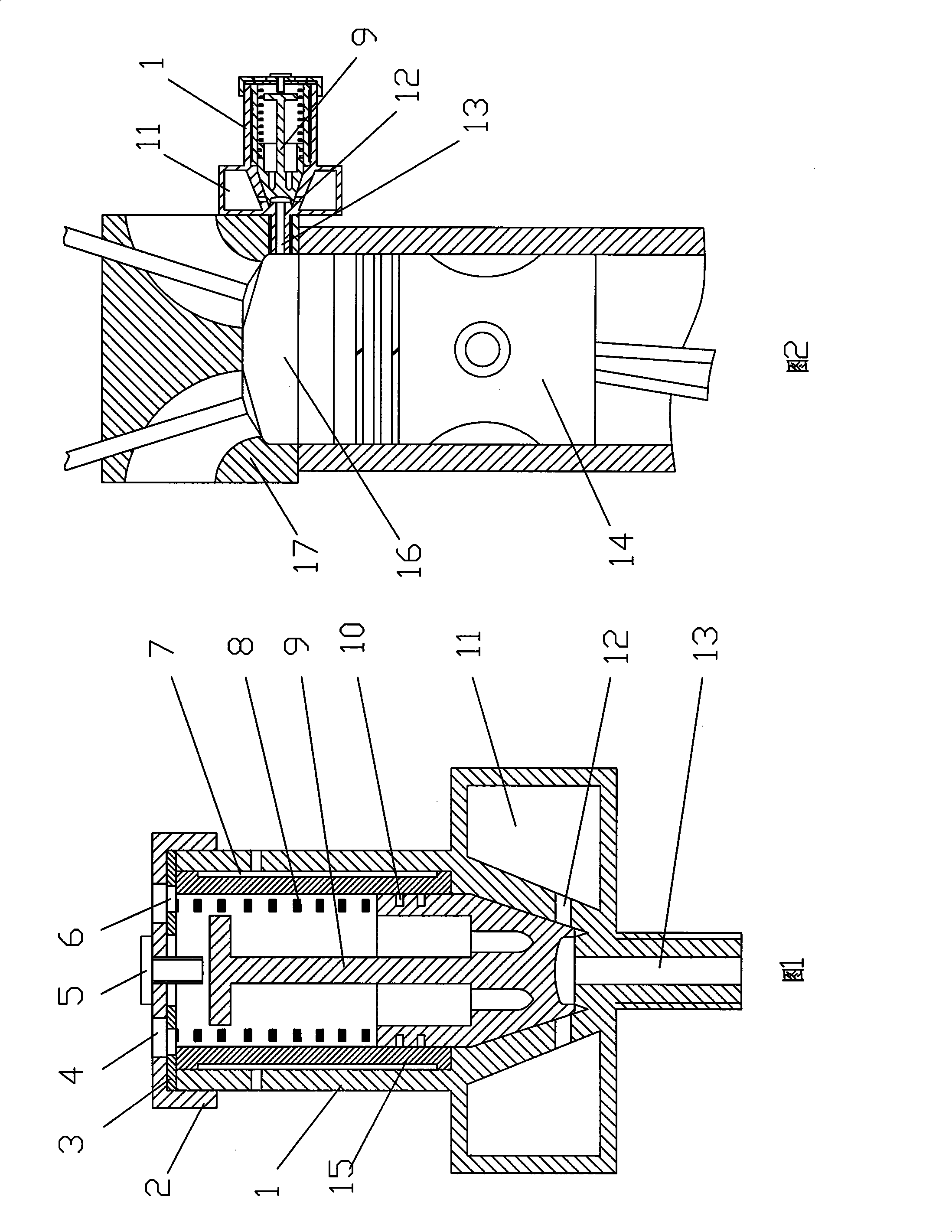

[0010] Referring to Figure 1 and Figure 2, one end of the buffer pressure storage valve body 1 is provided with a communication pipe 13 connecting the combustion chamber 16 and the buffer pressure storage valve body 1, and the buffer pressure storage valve body 1 of the explosion-proof buffer pressure storage valve is installed on the On the cylinder head 17, the other end is provided with the compression nut 2 of the first through hole 4 and the adjusting gasket 3 of the second through hole 6, and a bushing 15 and a tapered sealing piston 9 are provided in the buffer pressure storage valve body 1 And its spring 8 and sealing ring 10, the adjustment bolt 5 corresponding to the tapered sealing piston 9 is provided on the compression nut 2, the pressure storage chamber 11 is provided on the buffer pressure storage valve body 1, and a communication pressure storage The third through hole 12 between the chamber 11 and the combustion chamber 16, the tapered sealing piston 9 cuts off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com