Spiral traverse baffle shell type heat exchanger design method

A technology of shell-and-tube heat exchangers and spiral baffles, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., to achieve the effect of reducing waste of raw materials and costs, and high design efficiency and accuracy

Inactive Publication Date: 2011-01-05

XI AN JIAOTONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But then the American ABB company bought out its related research results, and only very limited information was given in the published literature for the detailed performance analysis and design methods of the heat exchanger.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

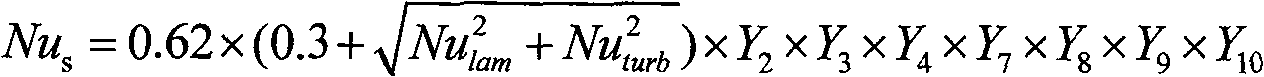

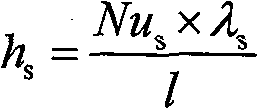

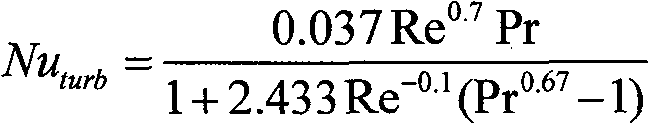

The invention relates to a design method for a screw deflector shell and tube exchanger. Firstly, the method for computing the pressure drop on the shell side of the screw deflector shell and tube exchanger and a coefficient of heat transfer can be obtained after the correlation of the drag produced from the sweep of hypothetical pipe columns by fluid and heat exchange is adjusted by referring tothe adjustment factors relevant to geometric structure parameters of the screw deflector shell and tube exchanger. Subsequently, a method for designing the process and geometric parameters of the screw deflector shell and tube exchanger according to the known thermal parameters is proposed by adopting the Bell-Delawre design method which is widely used for designing a segmental baffle shell and tube exchanger based on the computing method. According to the design method provided by the invention, a heat exchange meeting the given heat load specification is designed more accurately and efficiently; the design efficiency and the accuracy are high; the performance of the designed heat exchanger is closer to the performance required by the design specification; the raw materials and the cost wastage are significantly reduced.

Description

Design method of a shell-and-tube heat exchanger with spiral baffles technical field The invention relates to a design method of a heat exchanger, in particular to a design method of a shell-and-tube heat exchanger with spiral baffles. Background technique Shell and tube heat exchanger is an important equipment in oil refining, chemical industry, environmental protection, energy, electric power and other industries. Among them, the bow-shaped baffle shell-and-tube heat exchanger has the longest history. Although the bow-shaped baffle shell-and-tube heat exchanger is the most widely used shell-and-tube heat exchanger in the heat exchanger industry, due to its structural characteristics, there is a large pressure drop along the process; it is prone to flow dead zones; Fouling and easy to induce vibration of heat exchange tubes and other shortcomings, researchers have been improving its structure for a long time, but they have not been able to break away from its basic struc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F28D7/10

Inventor 张剑飞陶文铨何雅玲

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com