Semi-automatic design method for insert pin hole in die-casting die

A die-casting mold and design method technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problem of automatic model opening of pin holes in die-casting molds, and inability to export die-casting mold cooling models and pins in batches Holes, inability to batch distinguish part model differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

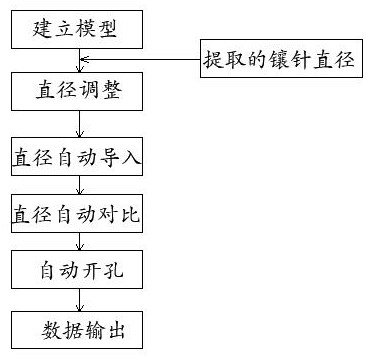

[0022] according to figure 1 , a semi-automatic design method for pin holes in die-casting molds, including using the pin diameter extracted from the shape of the die-casting product as the design basis, and automatically and batch-based the extracted pin diameters according to the pin design through the written software program Adjust the standard, and then automatically import the basic model of the insert in batches according to the adjusted diameter of the insert, and automatically open holes in the model in batches on the target part model, and output the relevant design information of the insert, eliminating existing repetitive operations in an automated form, ensuring The pinhole design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com