Air-actuated adjustable welding assembly used for large density battery

An adjustable battery technology, applied in the direction of electrical components, lead-acid batteries, battery components, etc., can solve the problems of high one-time investment, loose lead paste, low work efficiency, etc., and achieve low personnel quality requirements, docking The effect of precise position and fast operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

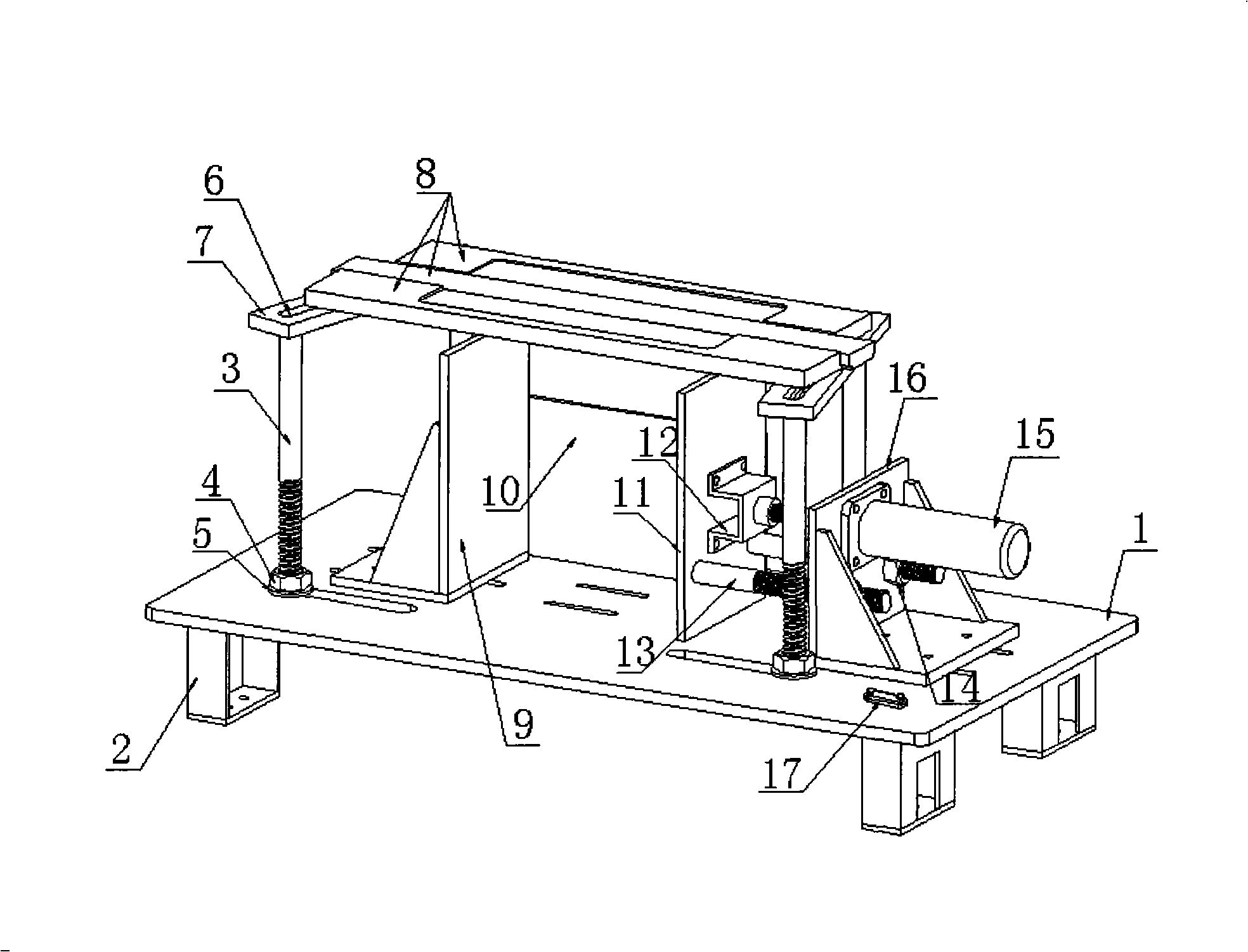

[0021] As shown in Figure 1, it consists of a worktable 1, a table support base 2, a table welding support and a pneumatic compression mechanism. Welding bracket and pneumatic compression mechanism; the table top welding bracket includes a support screw 3, a support plate 7 and a welding comb 8, and four support screws 3 are installed on the worktable 1 through nuts 4 and flat pads 5, and four The top of the support screw rod 3 is fixed to a support by installing two support plates 7 through bolts 6, and a welding comb plate 8 is installed on the support plates 7; Seat 16 forms, and cylinder 15 is installed by cylinder base 16 at the opposite side of front baffle plate 9, and cylinder base 16 is installed on the worktop 1, and the ejector rod of cylinder 15 cooperates pressing plate 11.

[0022] In the pneumatic adjustable welding tool for large and dense batteries of the present invention, the ejector rod of the cylinder 15 cooperates with the pressure plate 11 through the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com