Heat radiation system of nickel-hydrogen battery set for hybrid power vehicle

A technology for hybrid electric vehicles and cooling systems, which is applied in the layout of electric vehicles, power plant cooling combined, power plant, etc. problem, to achieve the effect of sacrificing heat dissipation strength, convenient operation, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below according to the accompanying drawings.

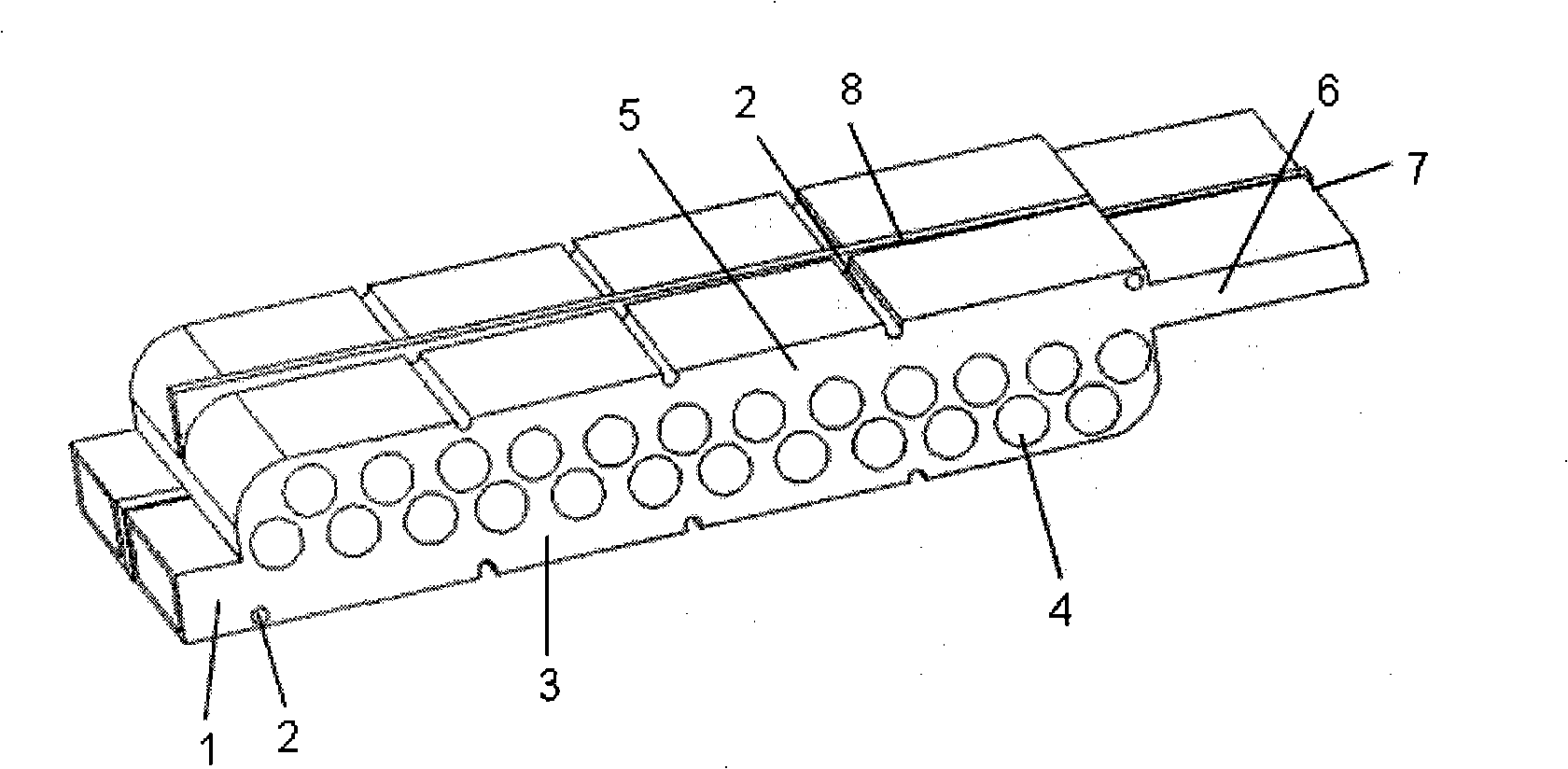

[0019] image 3 Shown is the structural diagram of the heat dissipation system for the nickel-metal hydride battery pack proposed by the present invention. The heat dissipation system includes: air inlet 1, support rod 2, air inlet channel 3, battery module and coated thermal resistance 4, outlet Air duct 5, air outlet 6, fan interface 7, battery support frame 8. An air inlet 1 is arranged at one end of the battery box, and an air outlet 6 is arranged at the other end, and the battery pack 4 is arranged in the battery box obliquely in upper and lower layers.

[0020] Such as Figure 4 As shown, it is a cross-sectional view of the Ni-MH battery pack heat dissipation system for hybrid vehicles proposed by the present invention. The two rows of battery packs respectively form wedge-shaped air inlet channels 3 connected to the air inlet 1 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com