Transfer plate and method for loading a cargo space

A transfer board and cargo location technology, applied in the transfer board field, can solve problems such as automation and inability to load materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

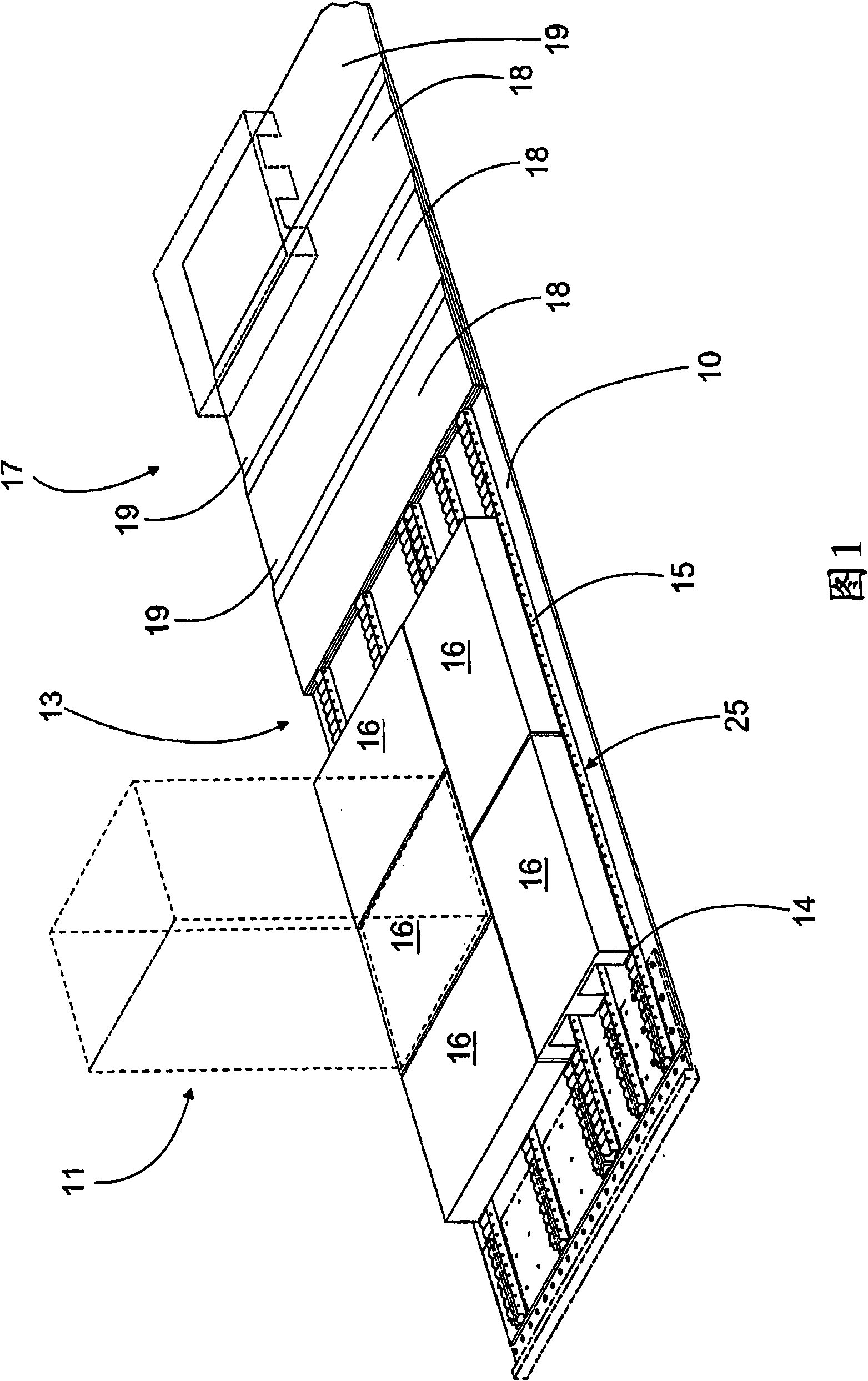

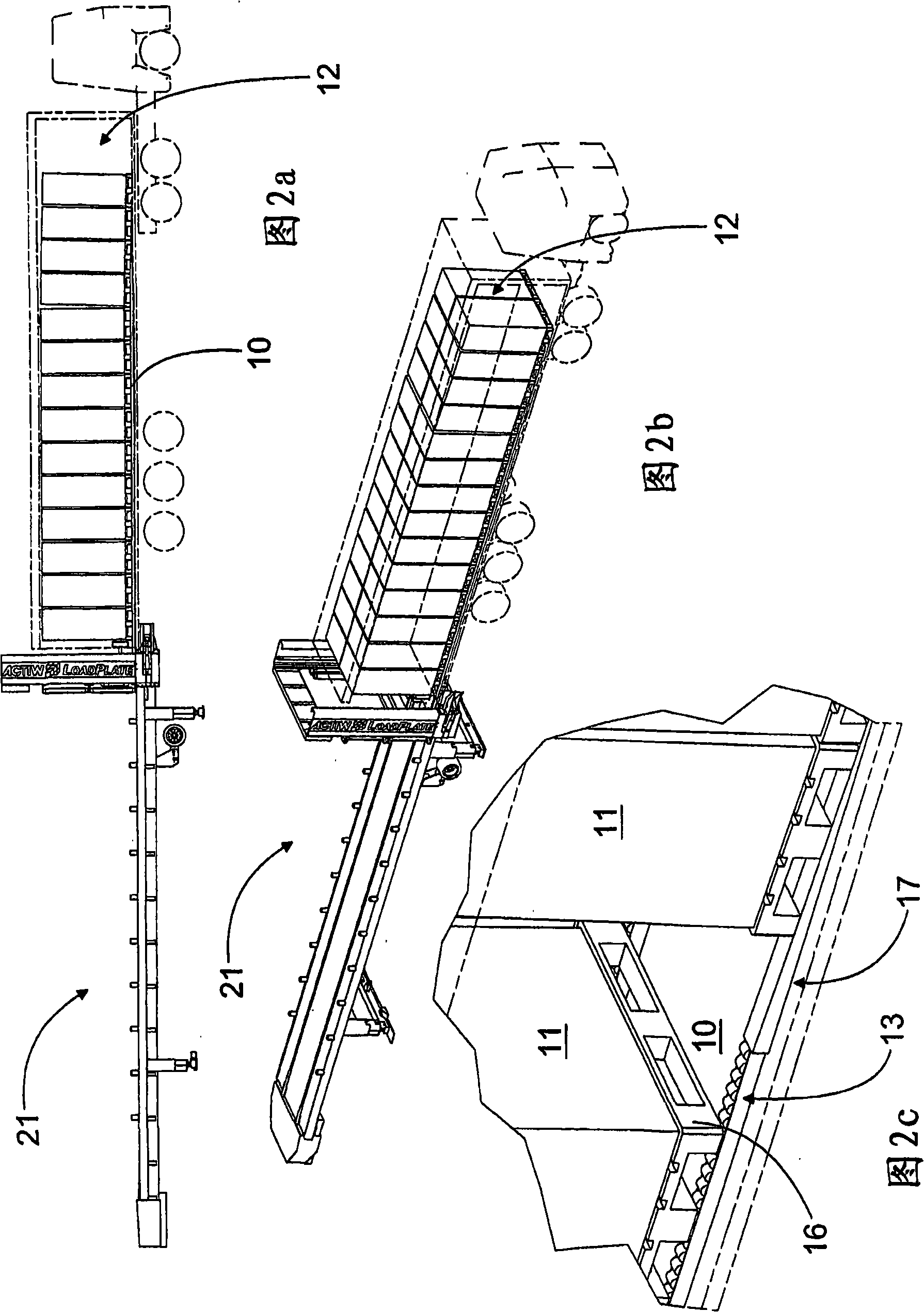

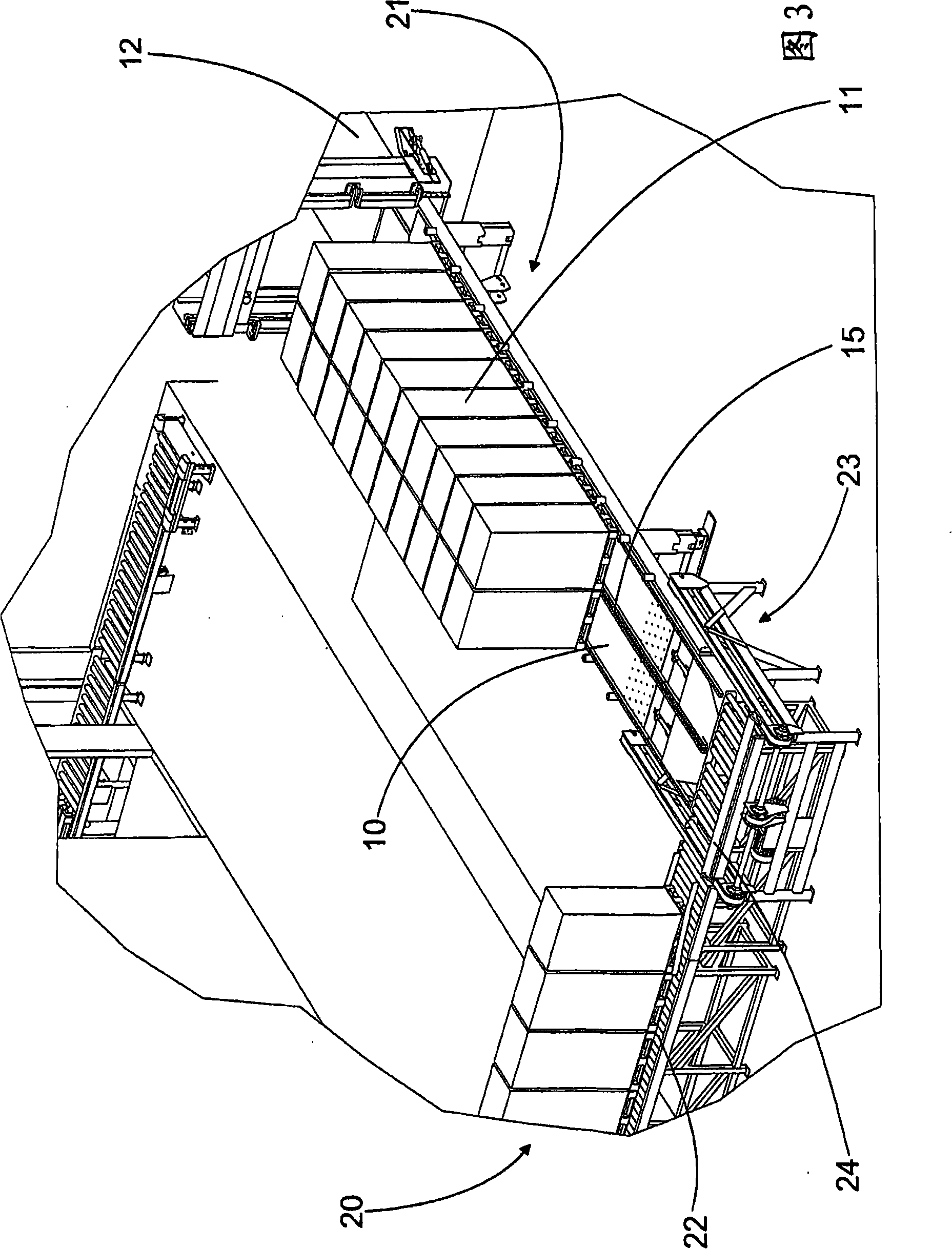

[0014] Figure 1 shows a conveyor plate 10 according to the invention, which is used when loading a storage space. The transfer plate 10 is intended to be transferred with the cargo units 11 to the storage space 12 and moves backwards while leaving the cargo units 11 in the storage space 12 (Figs. 2a and 2b). According to the invention, rolling elements 13 are mounted on the conveyor plate 10 on its surface facing the cargo unit 11 over part of its length so as to be movable between the conveyor plate 10 and the cargo unit 11 . The build-up of loads is thus facilitated and the stresses acting on the cargo unit and the transfer plate are apparently reduced from what is known. The stresses in the cargo unit and the remainder of the equipment are also reduced from those present.

[0015] The configuration, size and total number of rolling elements may vary in different applications. In the application shown, the rolling elements 13 are freely rotating rollers 14 by which the rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com