Multi-link lever suspension fork regulating mechanism

An adjustment mechanism, multi-link technology, applied in the direction of axle suspension, bicycle accessories, transportation and packaging, etc., can solve the problems of increasing danger, affecting driving feeling, stress concentration, etc., and achieving the effect of high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

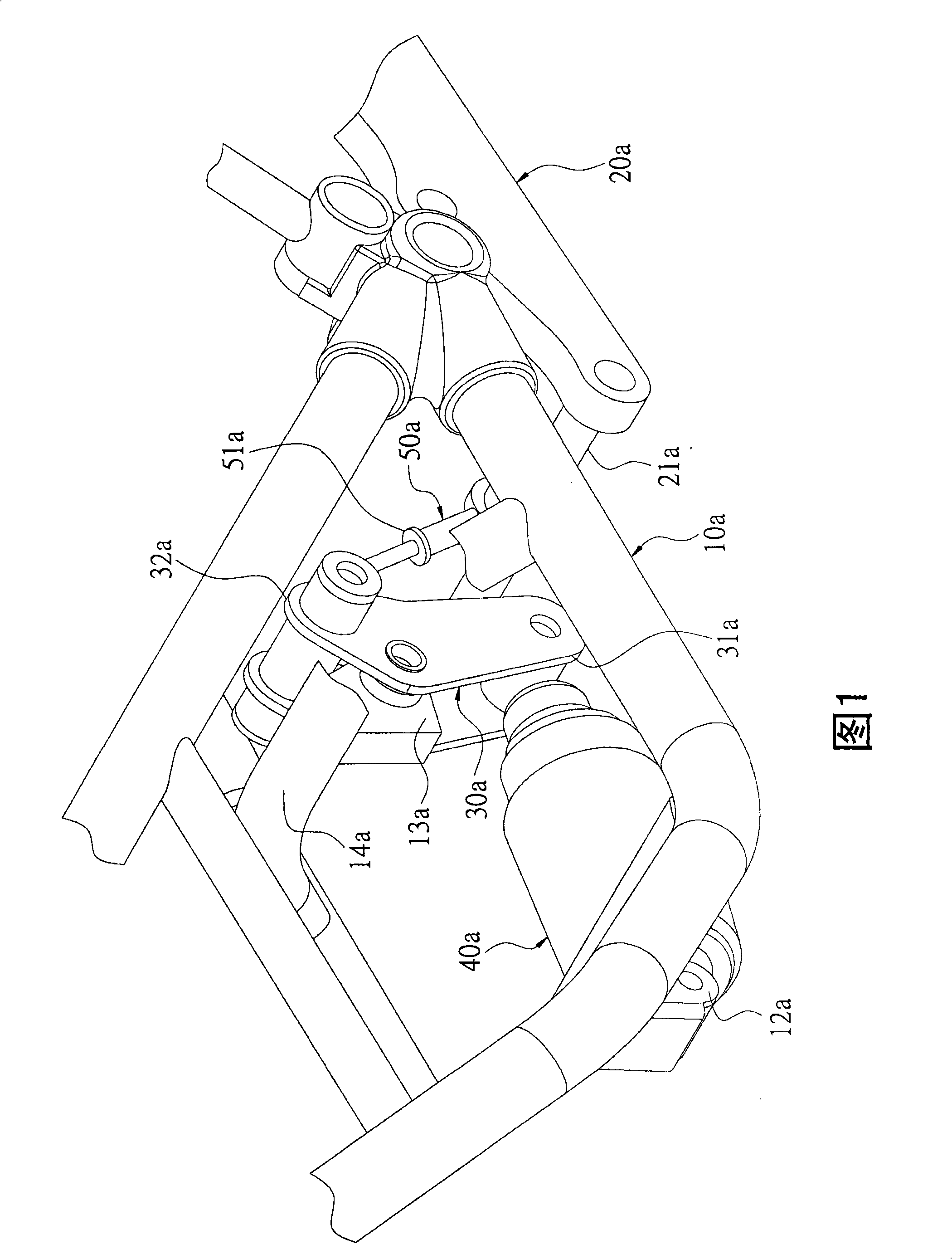

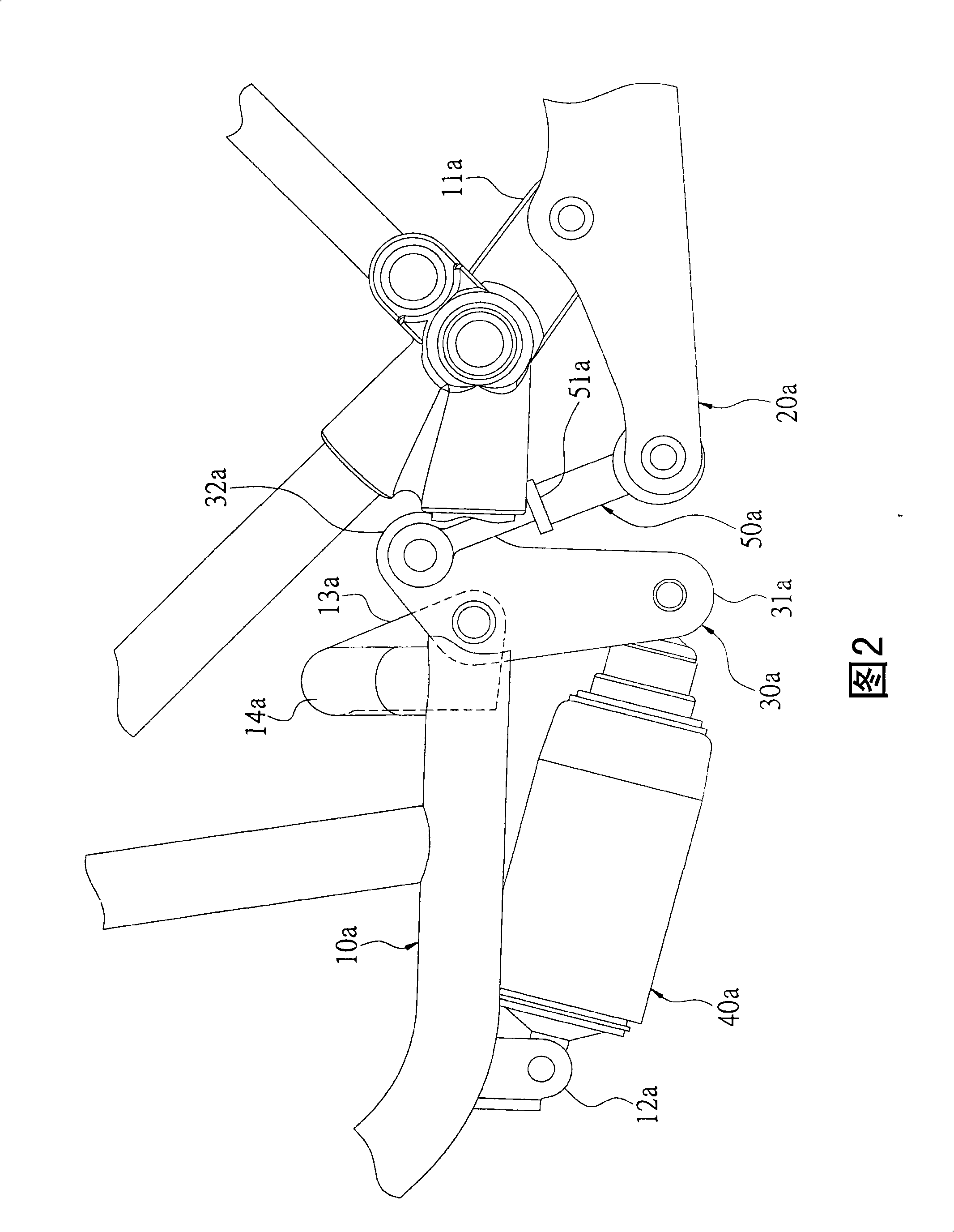

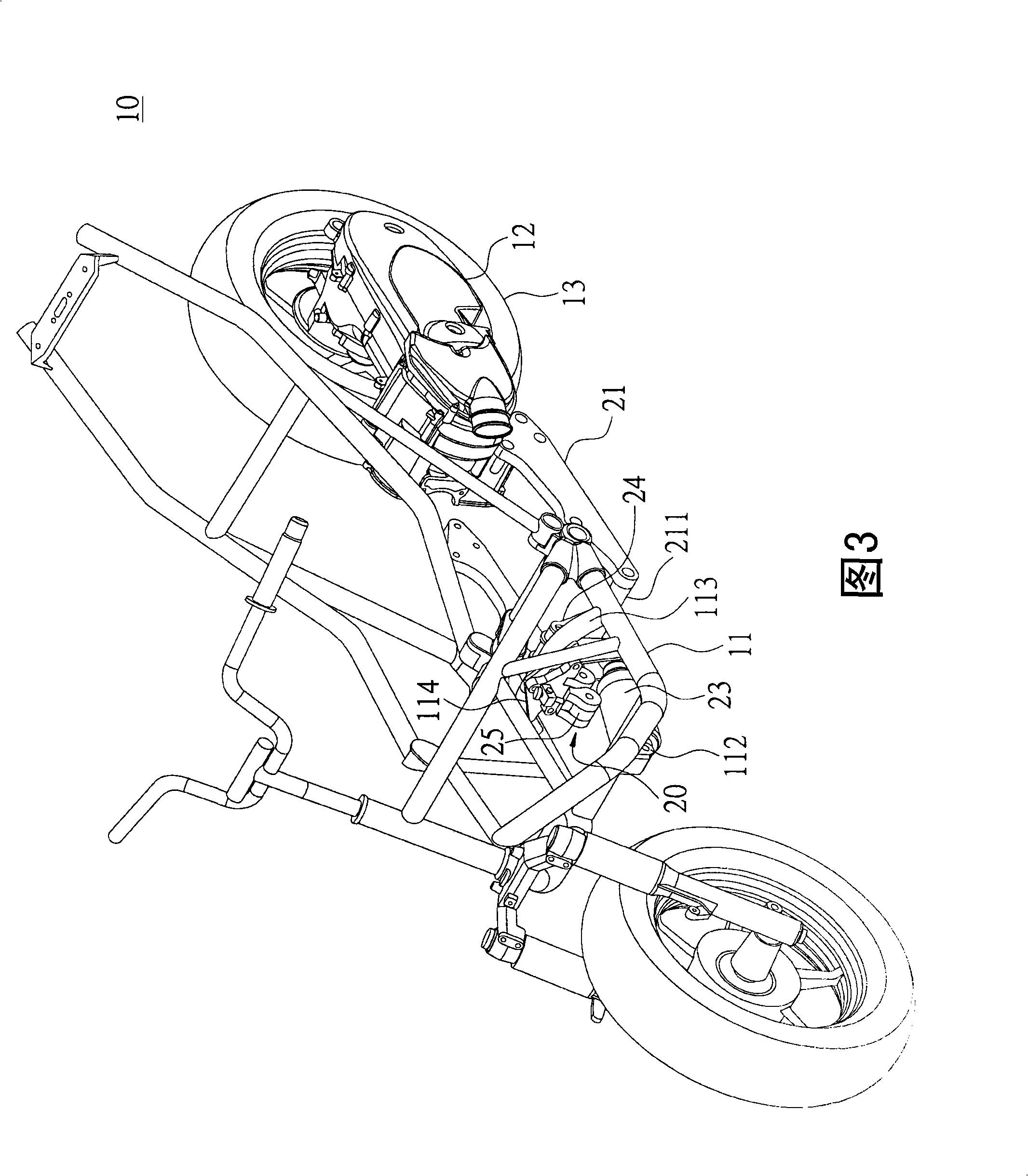

[0023] Please refer to Figures 3 to 6, which show the first embodiment of the present invention. This embodiment takes a two-wheeled vehicle 10 as an example for description, but the present invention is not limited to being applied to the two-wheeled vehicle 10. It can be other types of vehicles, such as scooter vehicles, gear-shifting vehicles, and power vehicles, among which the power vehicles are all-round off-road vehicles (ATV), golf carts, and snow-mobile vehicles.

[0024] The motorcycle 10 has a frame 11 and a power unit 12, wherein the rear end of the frame 11 is provided with a first pivot seat 111 (as shown in FIG. 5) on opposite sides of the rear end, and a second pivot seat is provided at the front end. 112. The second pivot seat 112 is separated from the two first pivot seats 111 at a distance. The bottom of the frame 11 is provided with a transverse bracket 113. The transverse bracket 113 is connected with a triangular fixing piece 114. The rear side of the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com