Particle slide track

A particle and slideway technology, applied in the field of particle slideway, to achieve the effect of smooth sliding and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

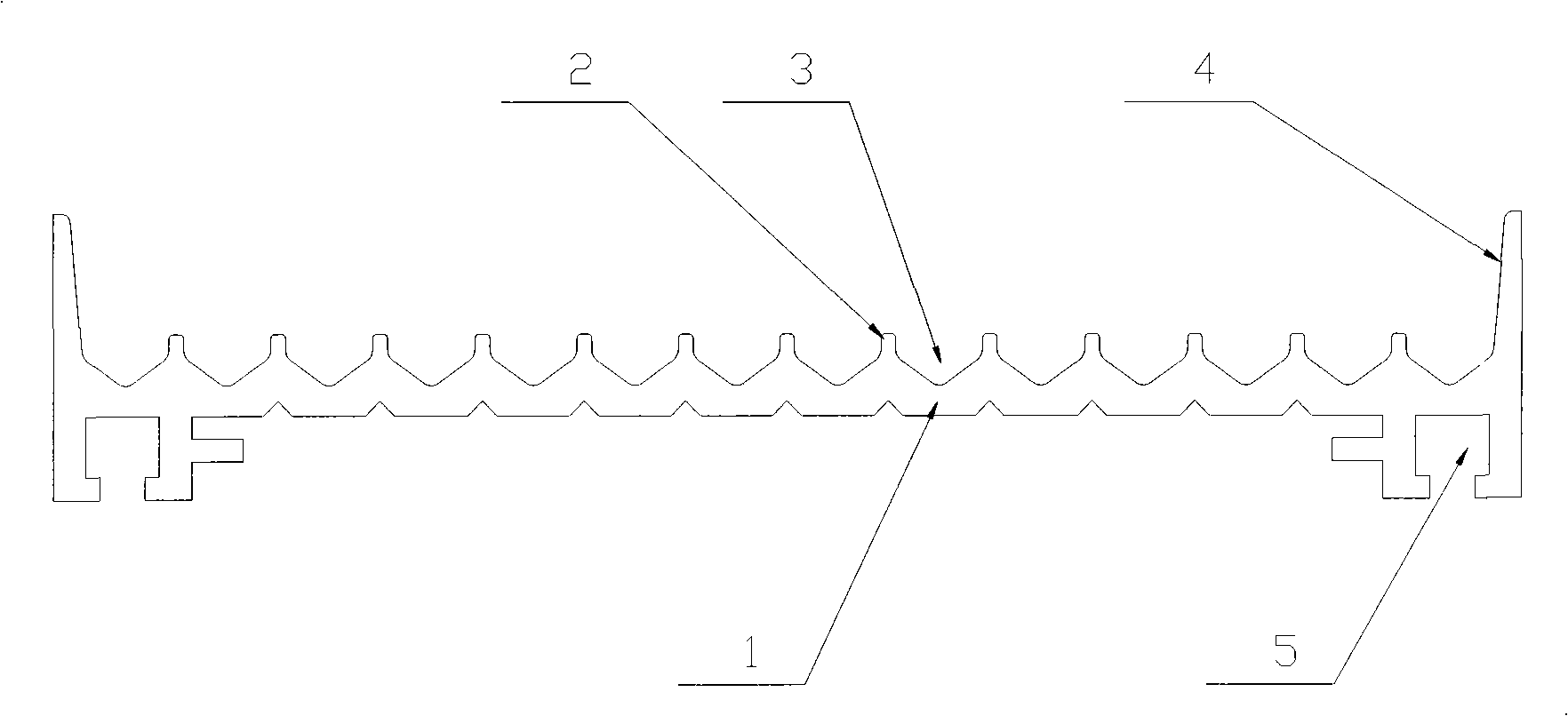

[0007] see figure 1 , the present invention improves a particle slideway, which includes a bottom plate and side walls arranged on both sides of the bottom plate, and a plurality of V-shaped grooves parallel to each other are arranged on the upper surface of the bottom plate.

[0008] The structures of the V-shaped grooves should generally be the same, and V-shaped grooves of different widths and shapes can also be provided according to different material properties and material handling requirements after sliding down.

[0009] Generally, the V-shaped grooves should be equally spaced.

[0010] The upper part of the walls of each V-shaped groove may be in the shape of a straight plate, so that the upper part of the V-shaped groove is a rectangle with equal width. The groove walls of adjacent V-shaped grooves may be shared, and the two V-shaped grooves are separated by the groove walls. Through the setting of the equal-width rectangular structure on the upper part of the V-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com