In-mold decorative injection molding mould and moulding method

A technology of injection molding and in-mold decoration, which is applied in the field of in-mold decoration injection molding and in-mold decoration injection molding molds, and can solve the problems that film inserts are easy to fall out of the mold cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

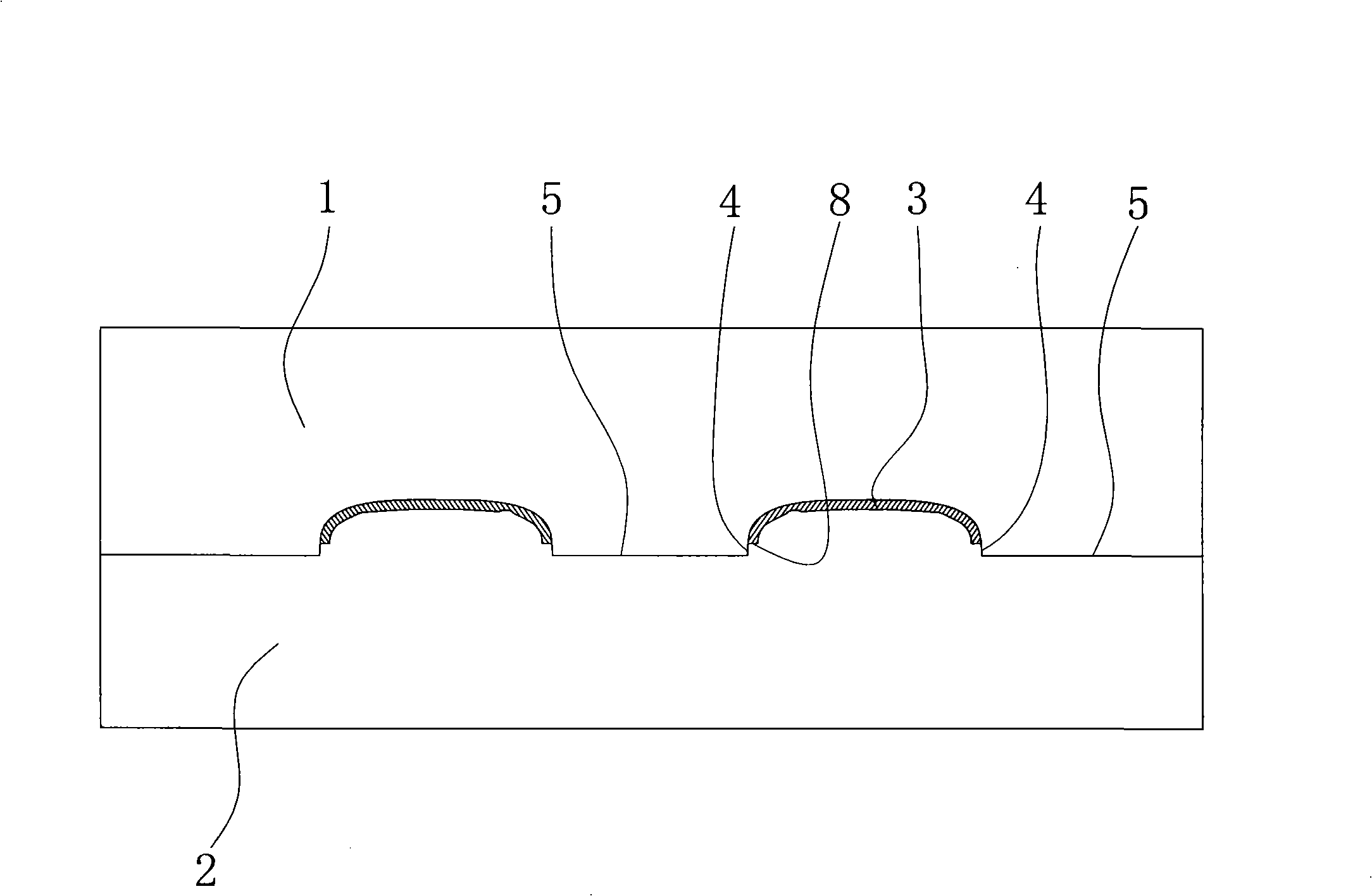

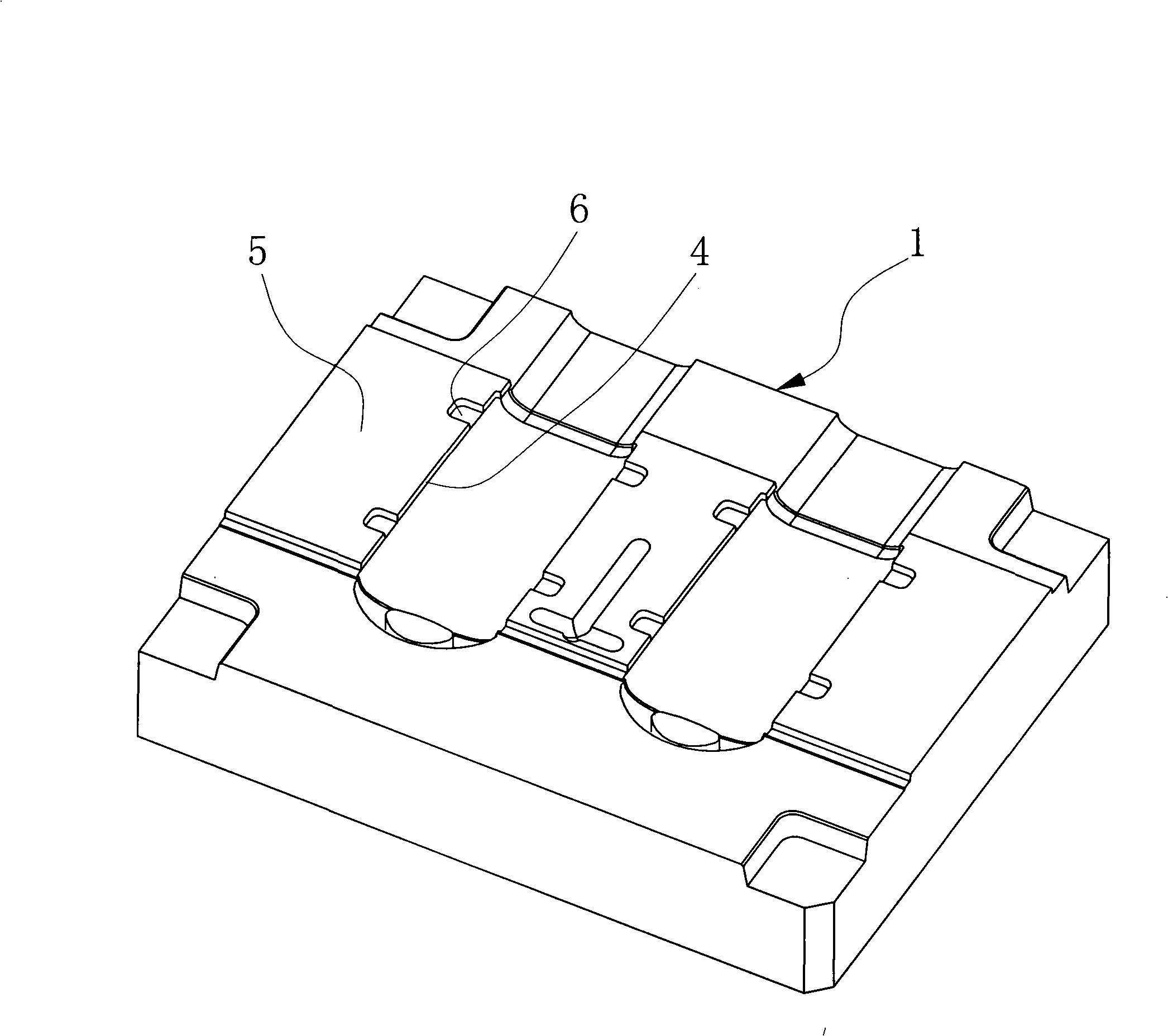

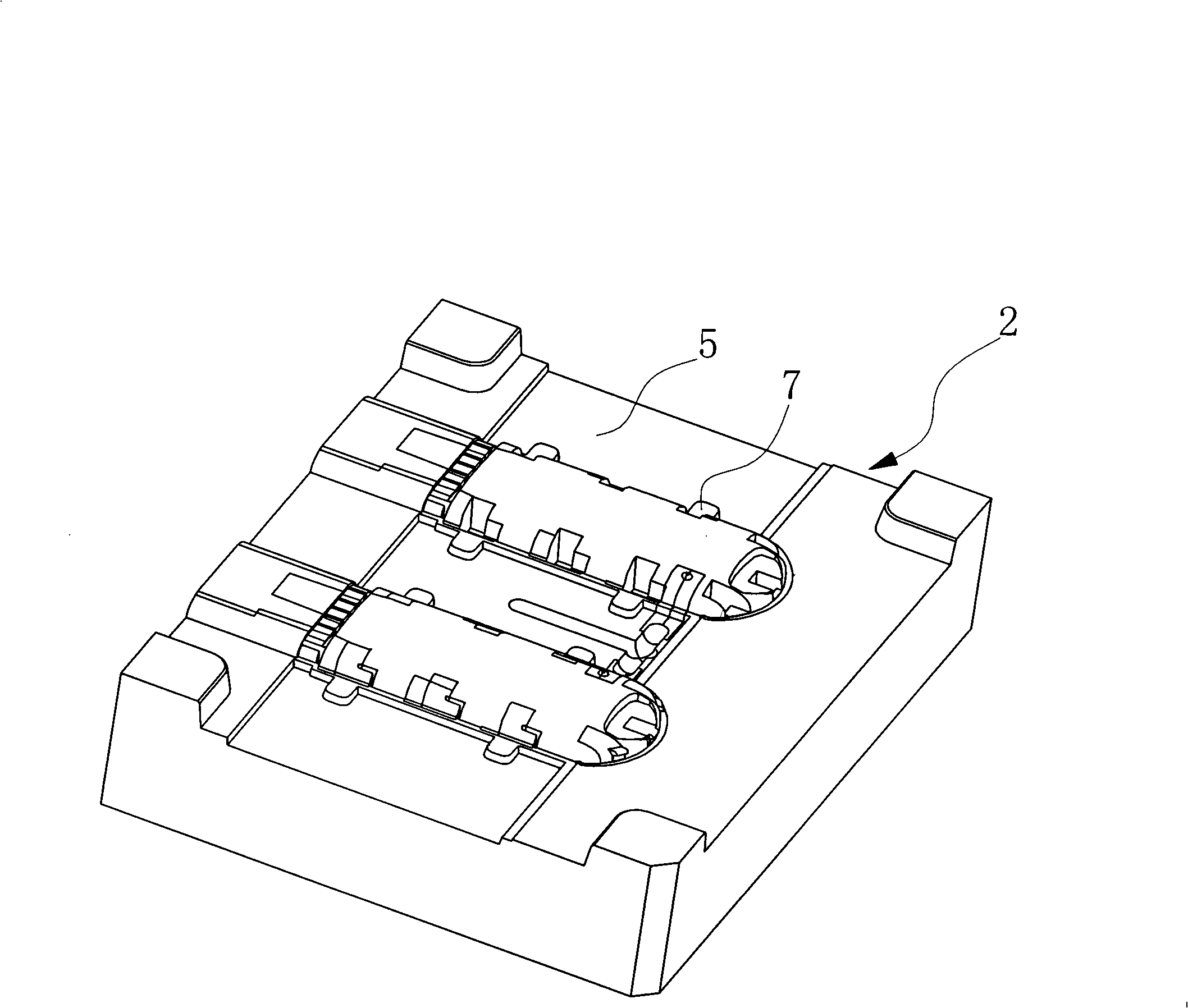

[0021] figure 1 , figure 2 , image 3 A preferred embodiment of the invention is shown.

[0022] see figure 1 , figure 2 and image 3 As shown, in this embodiment, the in-mold decoration injection molding mold is a one-out two mobile phone back cover injection mold. The mold cavity 3. The difference between this mold and ordinary molds is that the front mold 1 and the rear mold 2 extend from the position of the largest outer surface 8 of the product on both sides of the mold cavity along the mold opening direction to have an insertion surface 4, and then extend forward from the insertion surface 4. The penetration surface 5 of the mold and the rear mold, the penetration surface 4 and the penetration surface 5 constitute the parting surface of the mould. The front mold is distributed with four concave ears 6 around the mold cavity on the collision surface 5 extending from the insertion surface 4. The bottom surface of the concave ears 6 is flush with the largest outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com