Liquid soap bottle

A hand sanitizer and bottle body technology, applied in the field of hand sanitizer bottles, can solve the problems of waste of hand sanitizer, inconvenient use, difficulty in absorbing hand sanitizer, etc., and achieve the effect of deepening depth and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

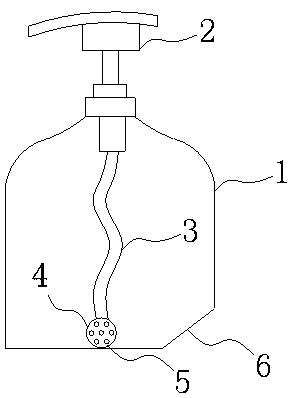

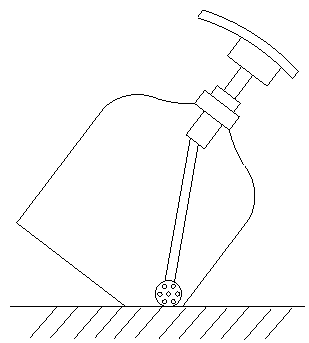

[0015] Such as figure 1 As shown, the hand sanitizer bottle of the present embodiment includes a bottle body 1, a pressing liquid outlet mechanism 2 and a liquid suction pipe 3 arranged in the bottle body 1; The key point is that the suction pipe 3 is made of flexible material, and the bottom end of the suction pipe 3 is provided with a load-bearing part 4 made of a heavier material (density greater than that of hand sanitizer). The liquid port 5 is located at the load-bearing part 4; one side of the bottom of the bottle is provided with an inclined plane 6, and the length of the pipette 3 is equal to the distance from the top of the pipette 3 to the inclined plane 6.

[0016] The load-bearing part 4 will sink to the bottom of the hand sanitizer bottle under its own gravity, so it can ensure that the hand sanitizer at the bottom of the bottle is sucked; The depth behind the bottom is relatively shallow, even if the liquid suction port 5 is brought to the bottom of the bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com