Base material for vehicle head liner

A base material, polyolefin-based technology, applied in the field of base materials for car roof linings, which can solve problems such as damage to health, easy deformation, pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Matters defined in the specification, such as detailed structures and components, are merely specific details to help those of ordinary skill in the art fully understand the present invention, and thus the present invention is not limited thereto.

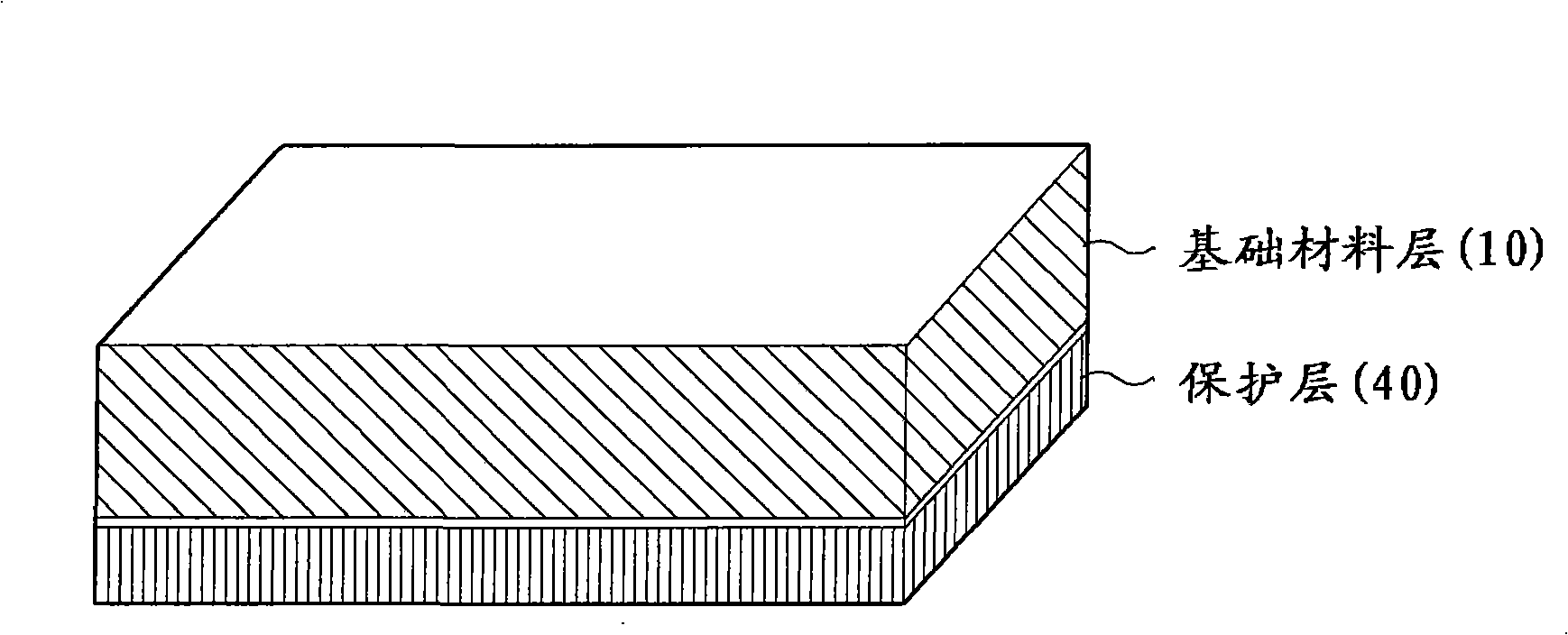

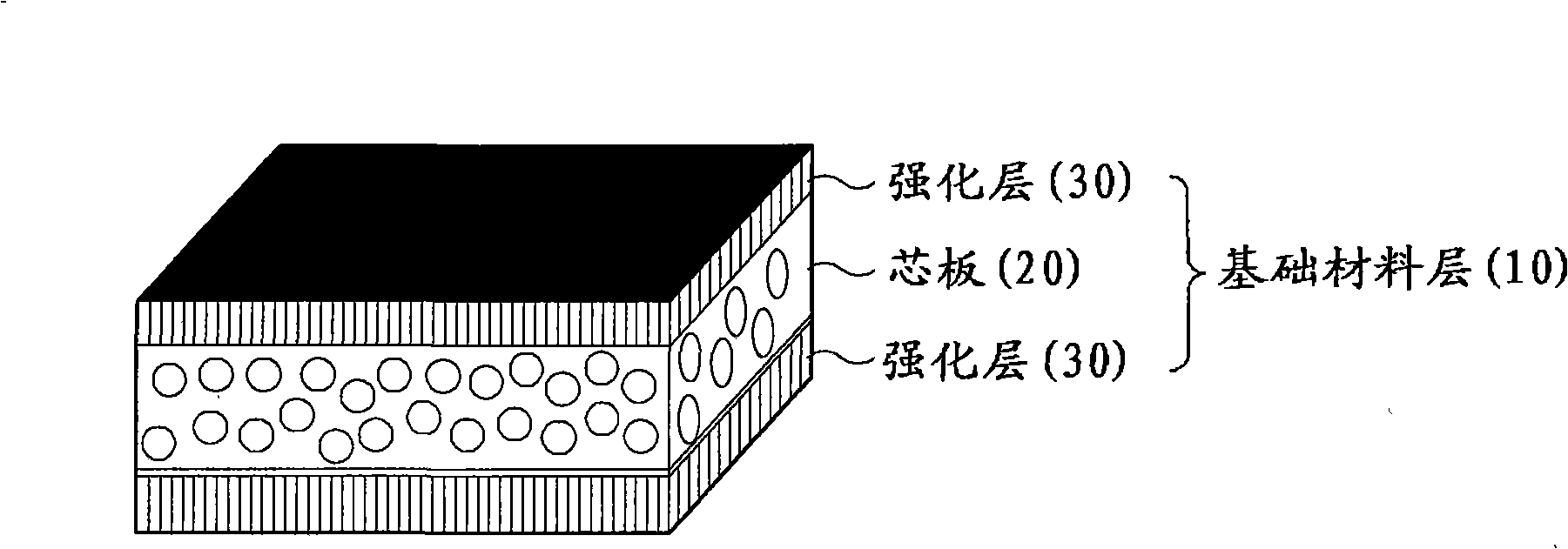

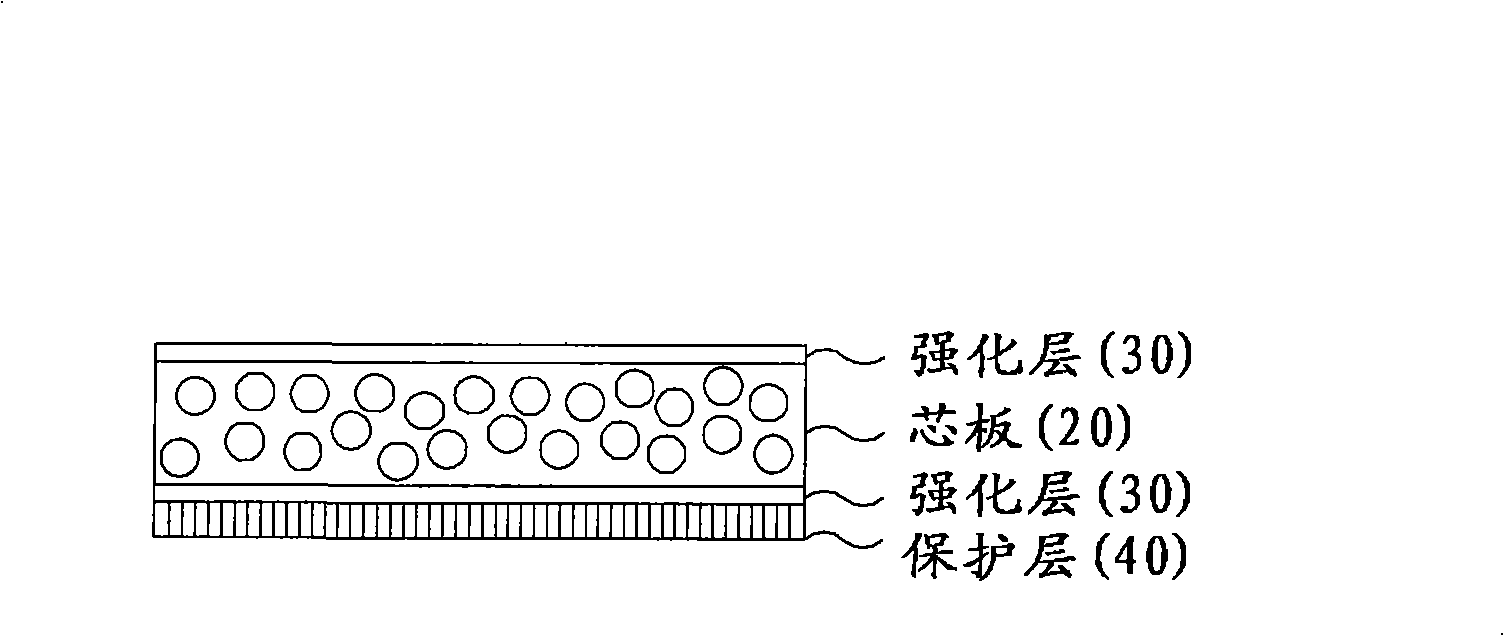

[0020] figure 1 is a view representing a conventional headliner. The roof lining comprises a base material layer 10 and a protective layer 11 . figure 2 is a view showing a base material for a roof lining according to an embodiment of the present invention. The roof liner of the present invention comprises a core layer 20 made of polyolefin-based foam board and a reinforcement layer 30 made of natural and synthetic fibers.

[0021] Preferably, the main component of the core layer is polypropylene and polypropylene with high melt tensile strength, and may contain linear low density polyethylene, low d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com