Wing structure having lamellar flow flowing control and separation control

A technology of flow control and separation control, applied in the field of wing structure, can solve problems such as stall, lift drop, separation, etc., to reduce frictional resistance and improve stall characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

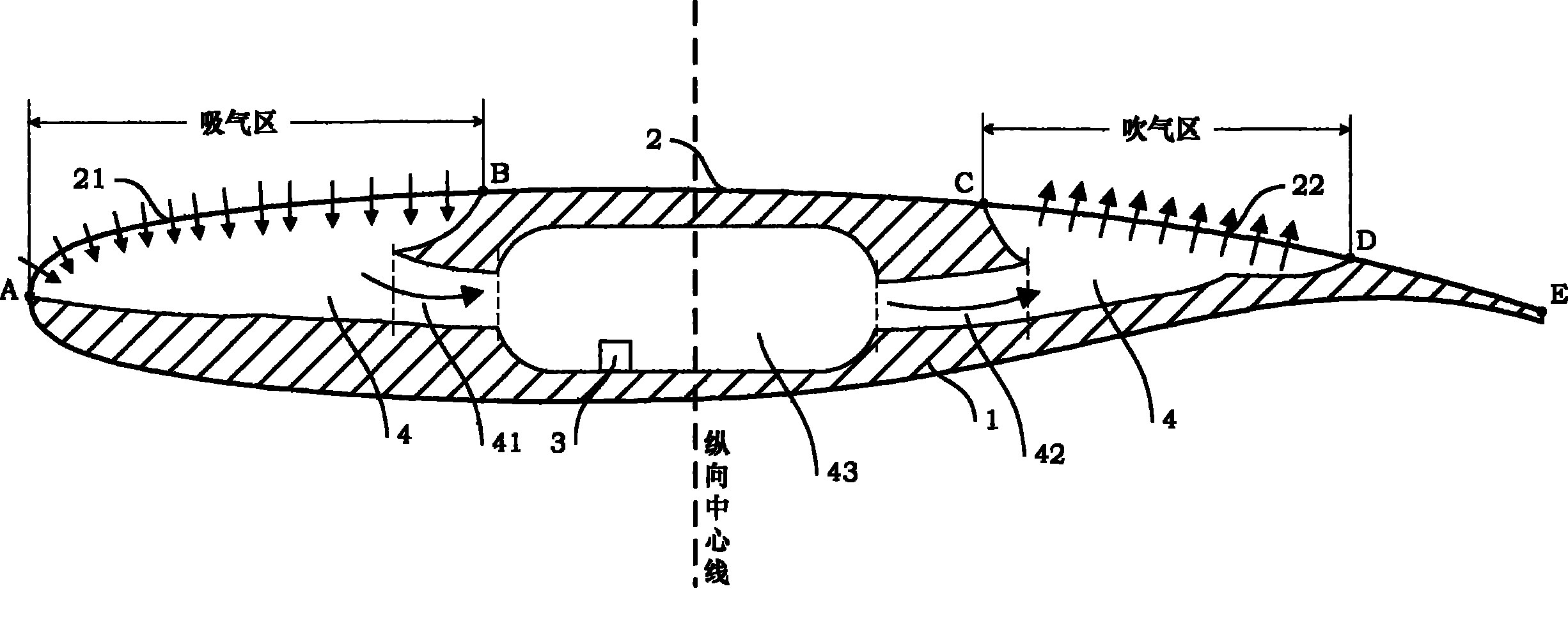

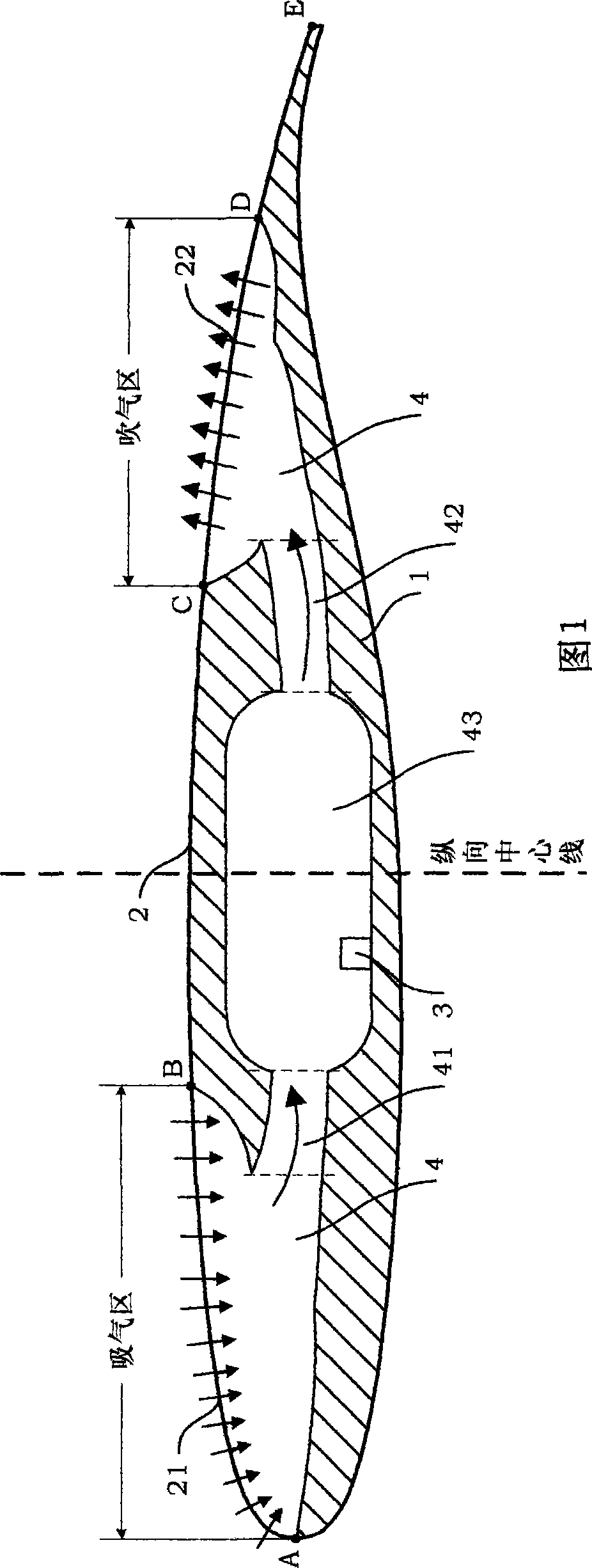

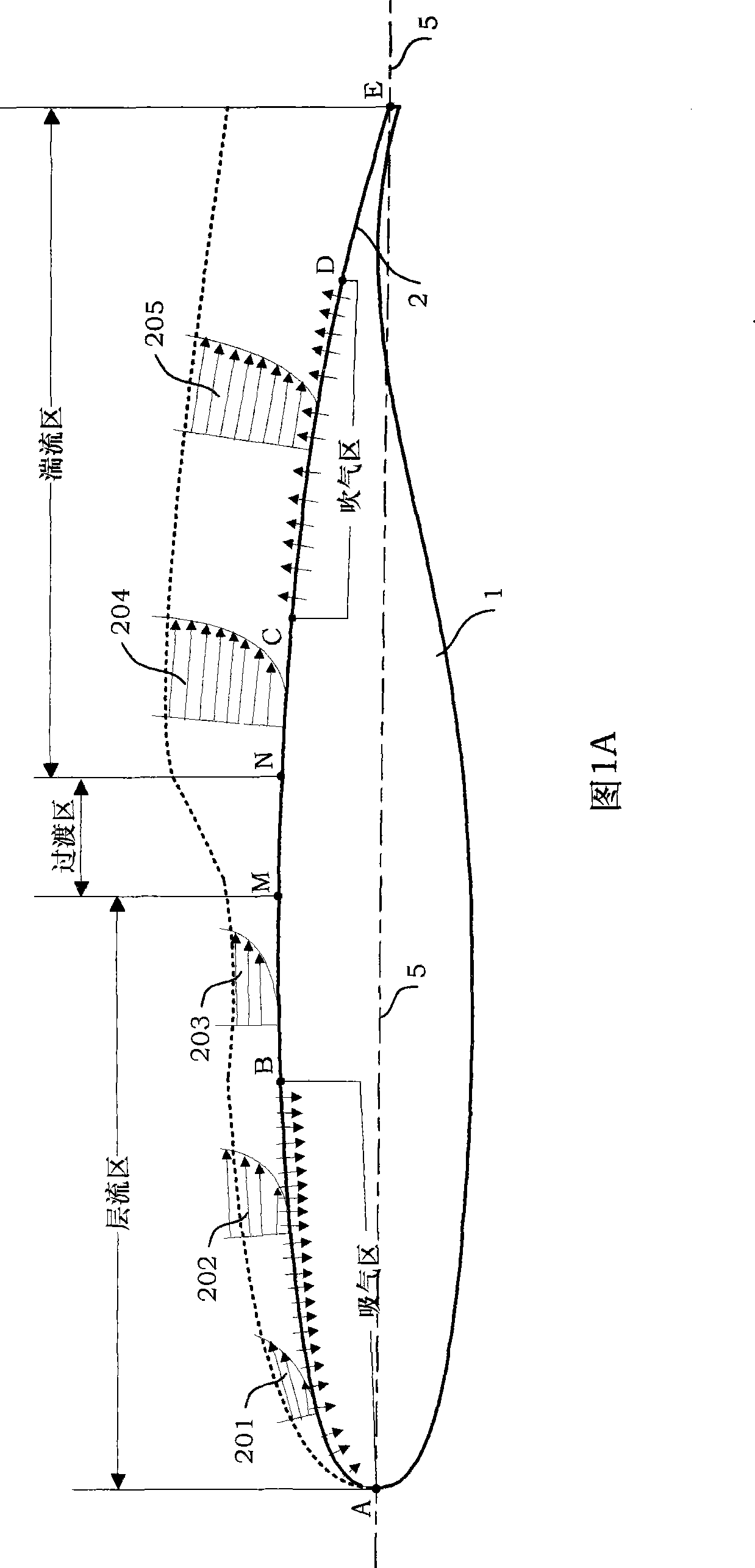

[0029] The wing structure with laminar flow control and separation control designed by the present invention is provided with a plurality of micropores with different apertures in the front and back of the upper airfoil 2 of the wing 1, and the micropores and airflow channels constitute suction, blowing passage, thereby changing the set point of the transition on the upper airfoil 2 of the wing 1. The delayed transition position can reduce frictional drag, control boundary layer separation, and improve wing stall characteristics. A plurality of suction pumps are set in the airflow channel, and by adjusting the blowing and suction volume, the low-speed fluid flowing through the bottom layer of the boundary layer on the surface of the leading edge of the airfoil can be sucked away, thereby making the boundary layer thinner and delaying the boundary layer from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com