Full section ladder energy dissipater

An energy-dissipating, full-section technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as increased energy dissipation rate, inability to guarantee energy dissipation rate, etc. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

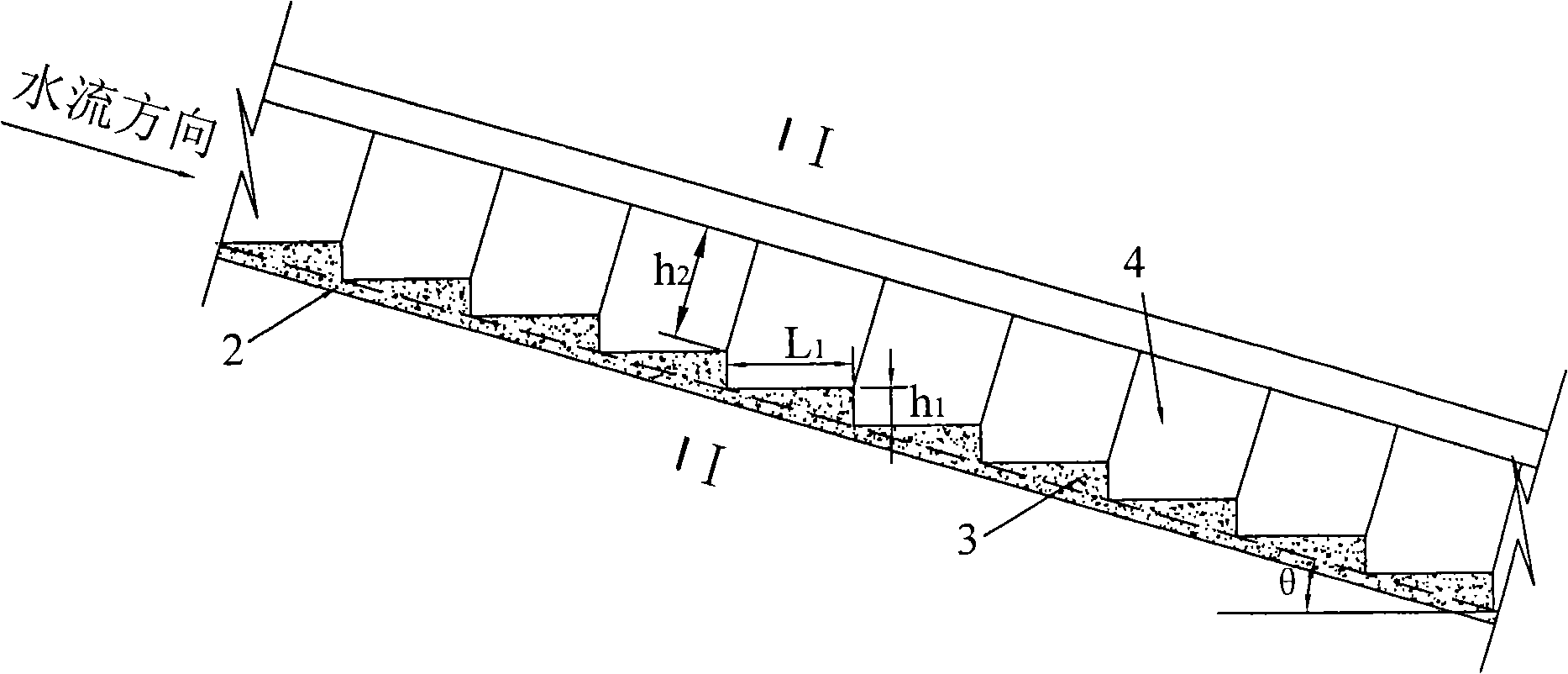

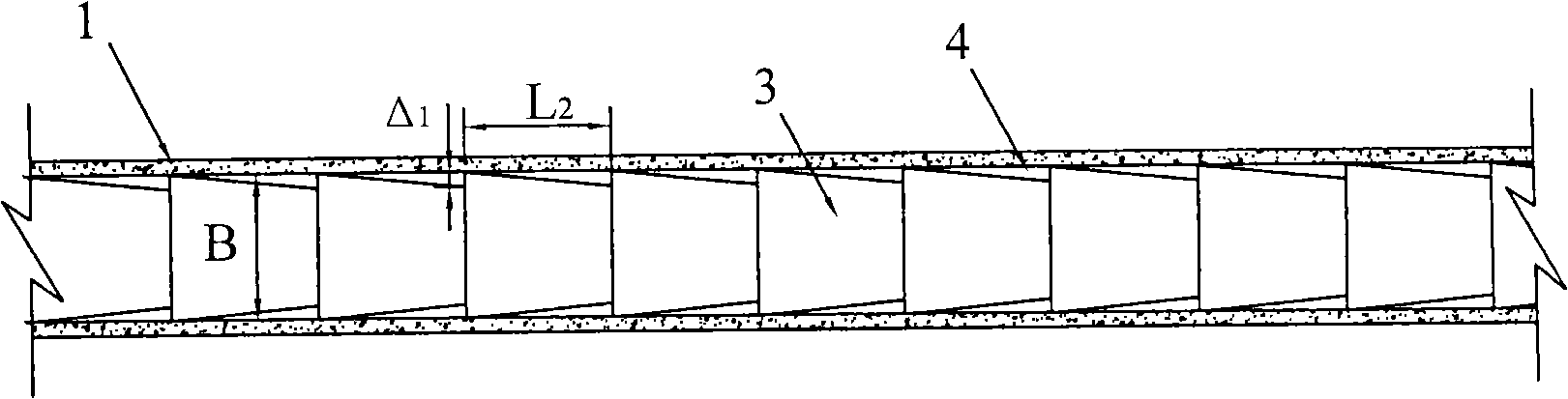

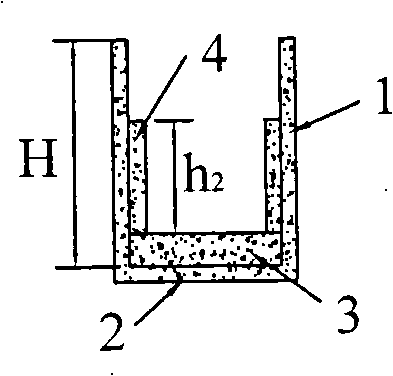

[0047] The full-section ladder energy dissipator in this embodiment is used in the project hub of the power station, the maximum working water head of the spillway of the power station is 140m, and the maximum discharge flow Q=1000m 3 / s, maximum single width flow q=100m 3 / s.m, spillway width B=10m, side wall height H=8m, floor slope θ is 15°.

[0048] The full-section ladder energy dissipator in this embodiment has a structure such as figure 1 , figure 2 , image 3As shown, it consists of stepped energy dissipators arranged on the spillway floor 2 and stepped energy dissipators arranged on the walls 1 on both sides of the spillway. The step of the ladder energy dissipator arranged on the spillway floor 2 is a horizontal step, the cross section of the step is triangular, and the step length is L 1 =7.5m, step height h 1 = 2m. The ladder shape of the ladder energy dissipator arranged on the walls 1 on both sides of the spillway is as follows: Figure 4 As shown, it is ...

Embodiment 2

[0051] The full-section ladder energy dissipator in this embodiment is used in a flood discharge tunnel of a hydropower station. The maximum working water head of the flood discharge tunnel is 150m, and the maximum discharge flow Q=1500m 3 / s, maximum single width flow q=150m 3 / s.m, spillway width B=10m, side wall height H=10m, floor slope θ is 25°.

[0052] The full-section ladder energy dissipator in this embodiment has a structure such as Figure 5 , Figure 6 , Figure 7 As shown, it consists of stepped energy dissipators arranged on the floor 2 of the spillway tunnel and stepped energy dissipators arranged on the walls 1 on both sides of the spillway tunnel. The step of the ladder energy dissipator arranged on the bottom plate 2 of the spillway tunnel is a horizontal ladder, the section of the ladder is triangular, and the length of the ladder is L 1 =4.3m, step height h 1 = 2.0m. The ladder shape of the ladder energy dissipator arranged on the walls 1 on both side...

Embodiment 3

[0055] The full-section ladder energy dissipator in this embodiment is used in the project hub of the power station, the maximum working water head of the spillway of the power station is 140m, and the maximum discharge flow Q=1000m 3 / s, maximum single width flow q=100m 3 / s.m, spillway width B=10m, side wall height H=8m, floor slope θ is 15°.

[0056] The full-section ladder energy dissipator in this embodiment has a structure such as Figure 8 , Figure 9 , Figure 10 As shown, it consists of stepped energy dissipators arranged on the spillway floor 2 and stepped energy dissipators arranged on the walls 1 on both sides of the spillway. The step of the ladder energy dissipator arranged on the spillway floor 2 is a horizontal step, the cross section of the step is triangular, and the step length is L 1 =7.5m, step height h 1 = 2m. The ladder shape of the ladder energy dissipator arranged on the walls 1 on both sides of the spillway is as follows: Figure 11 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com