Loose-leaf type internal corner formwork

A kind of internal corner formwork and loose-leaf technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, which can solve the difficulty of formwork disassembly and angle adjustment , inconvenient use and other problems, to achieve the effect of convenient standardized production, cost saving and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

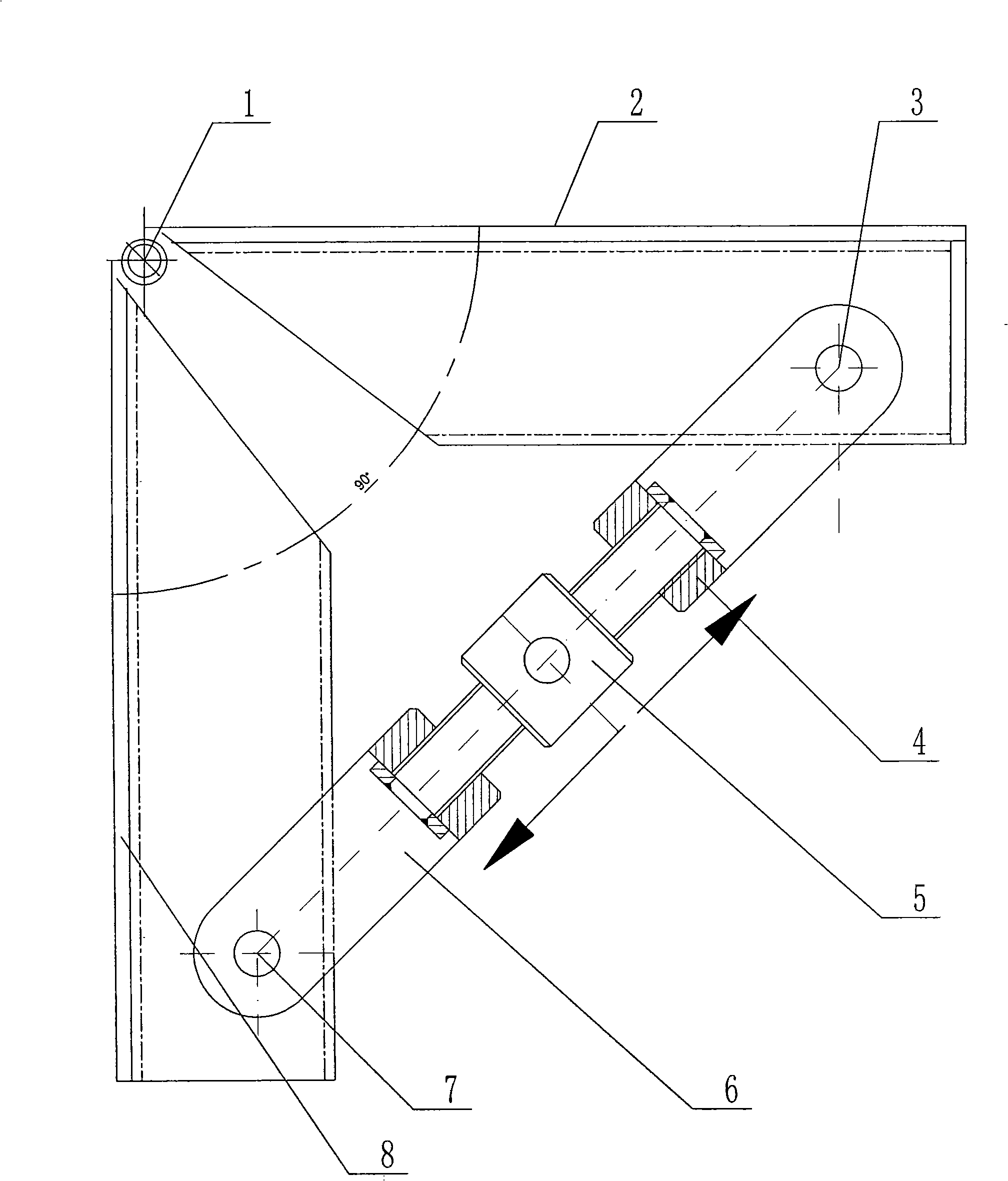

[0007] As shown in the figure, it is a loose-leaf internal corner template, including two template bodies 2 and 8 intersecting at the sidelines, and a hinge 1 is provided at the intersection of the two template bodies 2 and 8, and the two template bodies 2 and 8 can be Rotate around the hinge 1 to change the angle. Nuts 4 and 6 are hinged through the pin shafts 3 and 7 on the back of the template body 2 and 8. The threads of the two nuts 4 and 6 are positive and the other negative. The double-threaded adjusting rod 5 of anti-teeth can change the angle between the template body 2 and 8 by rotating the double-ended threaded adjusting rod 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com