Bipolar plate with microgrooves for improved water transport

A bipolar plate and micro-groove technology, applied in battery electrodes, fuel cell components, electrolyte treatment of solid electrolyte batteries, etc., can solve problems such as limiting long-term durability and increasing battery ionic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of embodiments are merely illustrative in nature and do not limit the invention, its application or use.

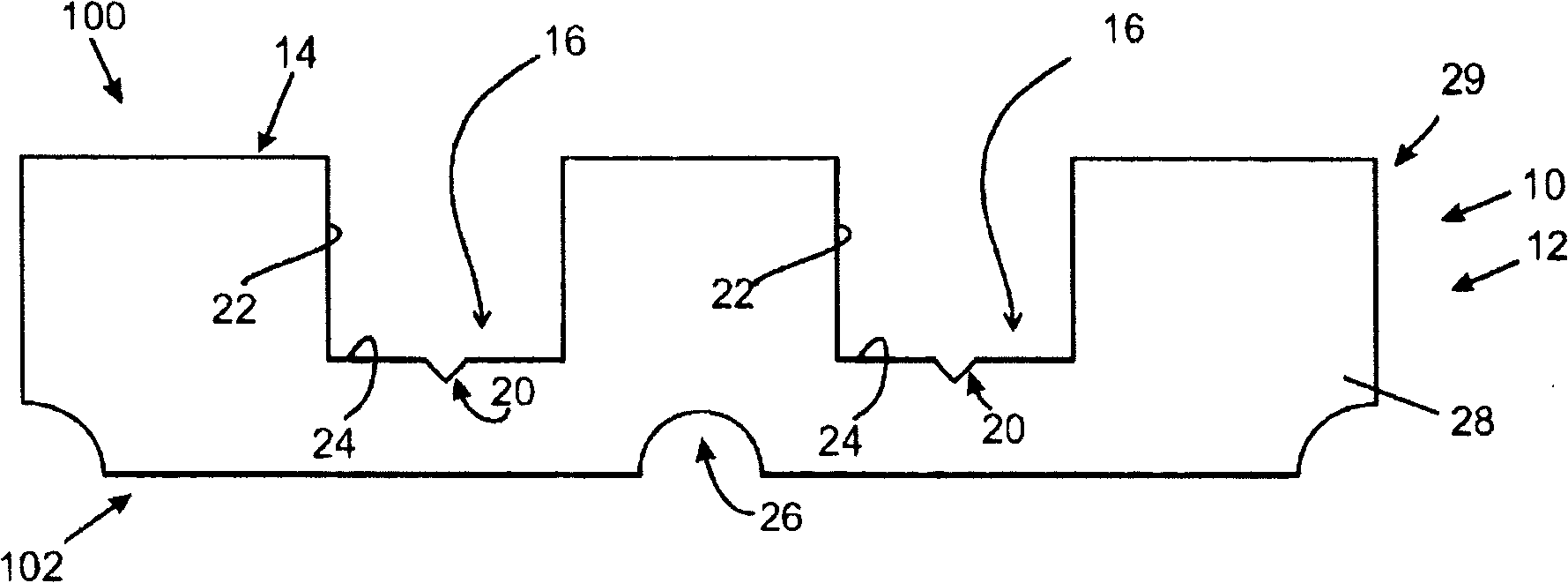

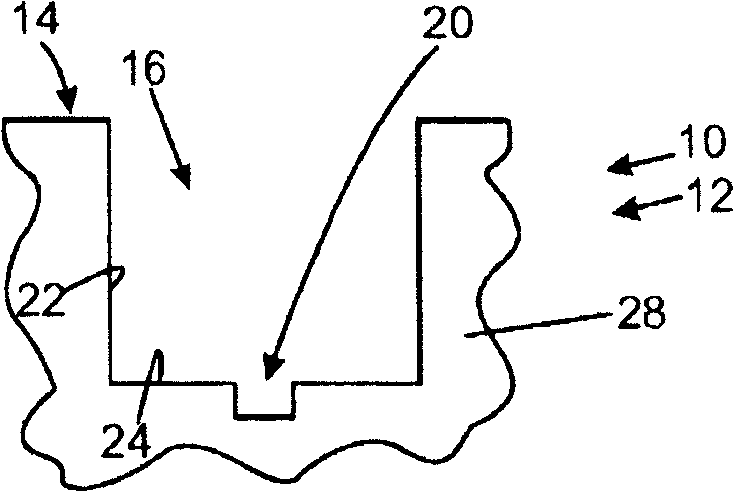

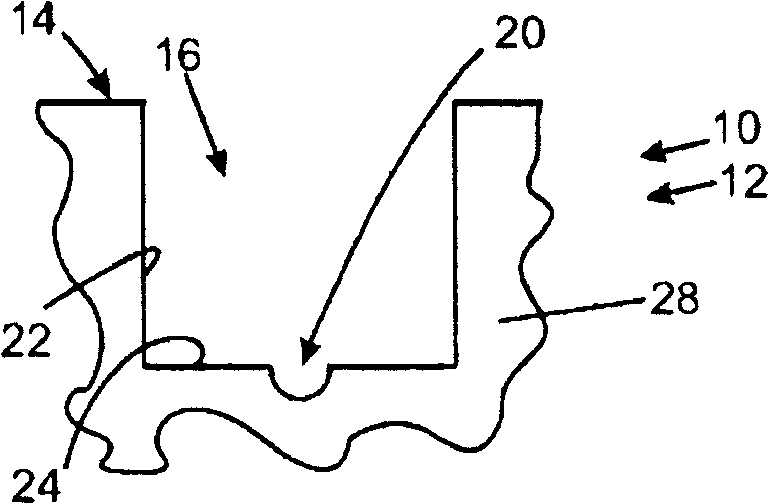

[0034] now refer to figure 1 , an embodiment of the invention includes a product 10 having a fuel cell bipolar plate 12 . The fuel cell bipolar plate 12 includes a substrate 29 . Substrate 29 includes base portion 28 and optionally one or more layers on base portion 28 . Base portion 28 includes a variety of materials including, but not limited to, metals, metal alloys, and / or conductive composite materials. Base portion 28 may include one or more layers.

[0035] The fuel cell bipolar plate 12 includes a first face 100 and an opposing second face 102 . The fuel cell bipolar plate 12 includes a reactant gas flow field defined at least in part by a plurality of platforms 14 and channels 16 in a first face 100 . Channel 16 is defined by side walls 22 and a bottom surface 24 . Cooling channels 26 may be formed in second face 102 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com