Front hatch having cantilever hatch-operating mechanism

A front cabin, cantilever beam technology, applied in transportation and packaging, air resistance reduction technology, railway car body and other directions, can solve the problem of complex volume of the coupler mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

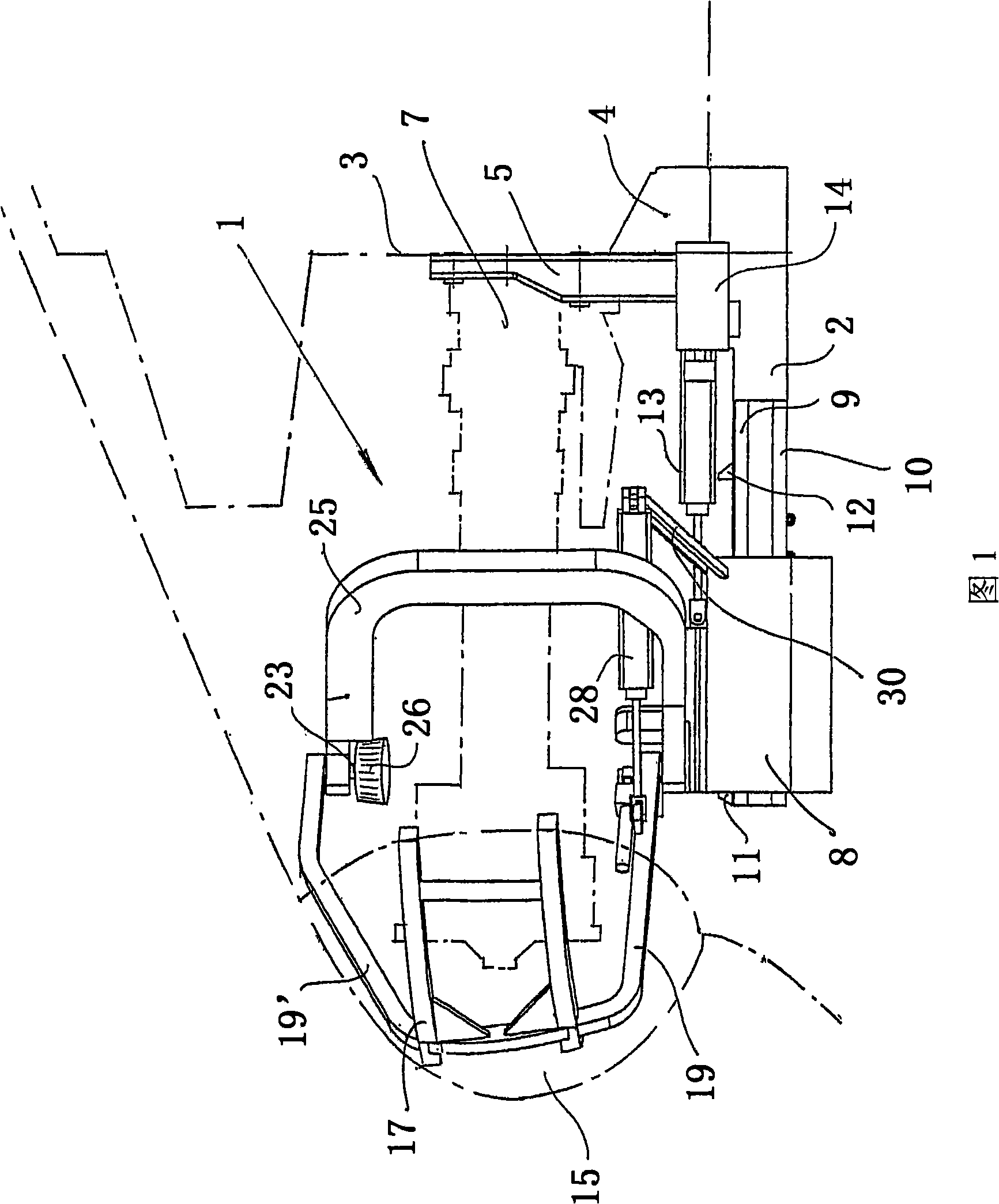

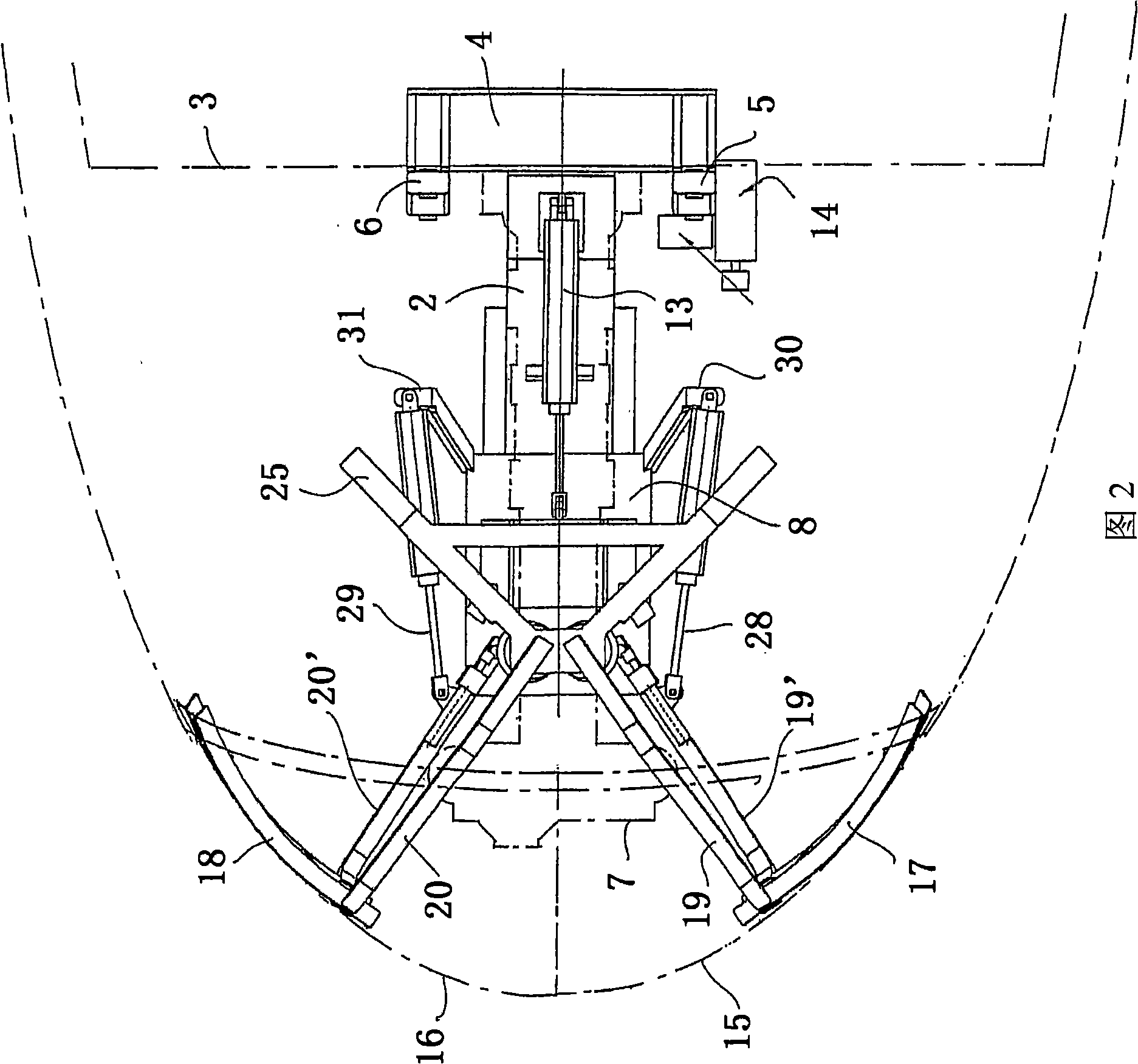

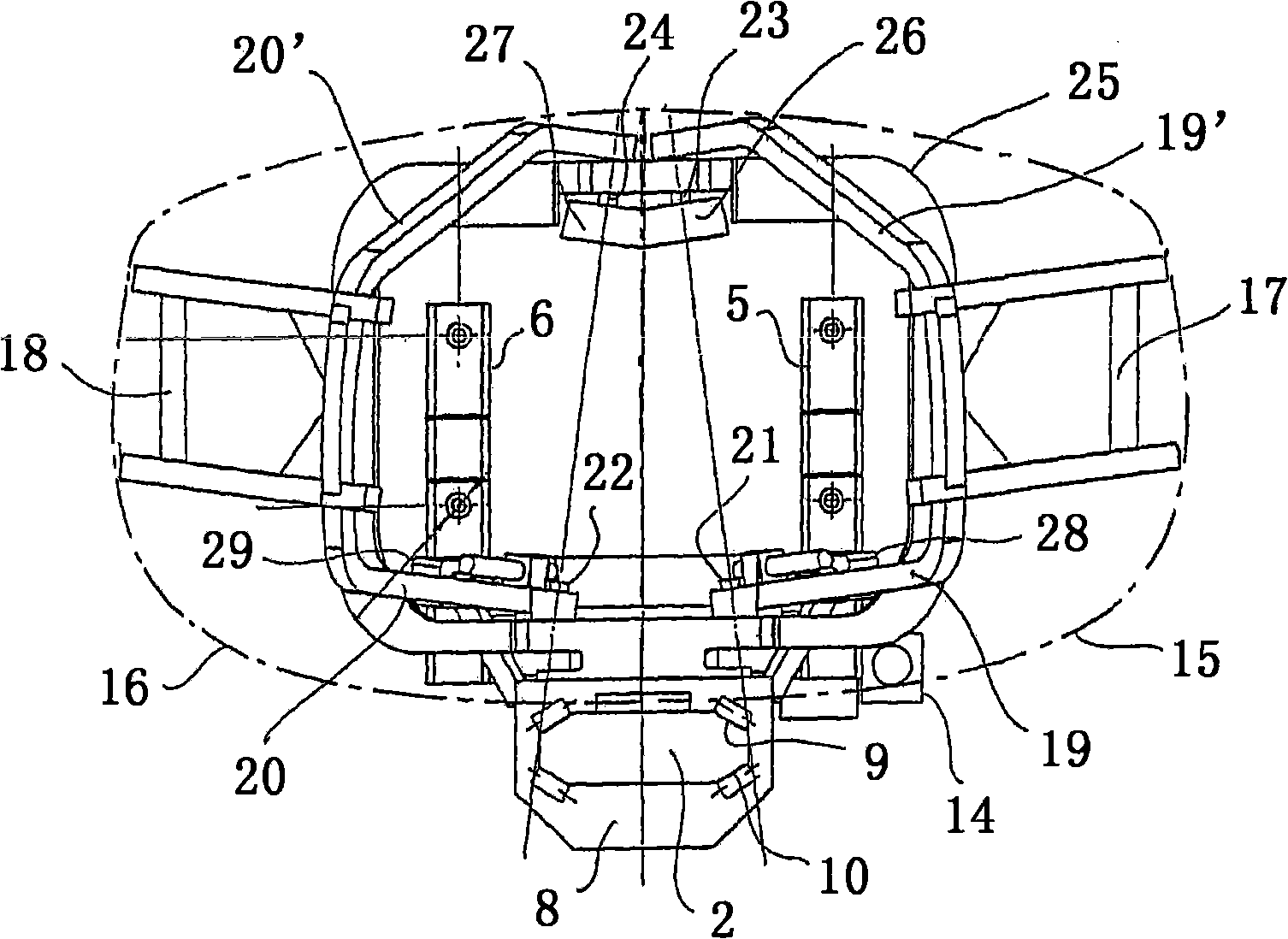

[0023] The figure illustrates the mechanism for operating the front compartment in the body of a railway vehicle, wherein the outlines of the body of the vehicle, the vehicle chassis and the couplers supported by the chassis are schematically indicated in dashed-dotted lines in place.

[0024] Refer to Figure 1 to Figure 4 , an embodiment of the hatch door operating mechanism 1 according to the present invention will be described. When the front cabin is opened, the door operating mechanism 1 is arranged to move into the vehicle body under the guidance of the cantilever beam 2 . The beam 2 is mounted to the vehicle chassis 3 only at the inner end by connecting means designed and adapted to cooperate with the subject vehicle chassis. In the illustrated embodiment, the connection means comprise a transverse box or beam 4 having legs 5 and 6 projecting upwardly from its ends, the legs being arranged in a coupler 7 extending from the chassis Each side is bolted to the vehicle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com