Armrest drive force monitoring apparatus of passenger conveying equipment

A technology of passenger conveying equipment and monitoring devices, which is applied in escalators, transportation and packaging, etc., can solve the problems of undetectable driving force, increased equipment structure cost, and increased program processing burden, and achieves excellent detection accuracy and the shortest time Optimizing and improving the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

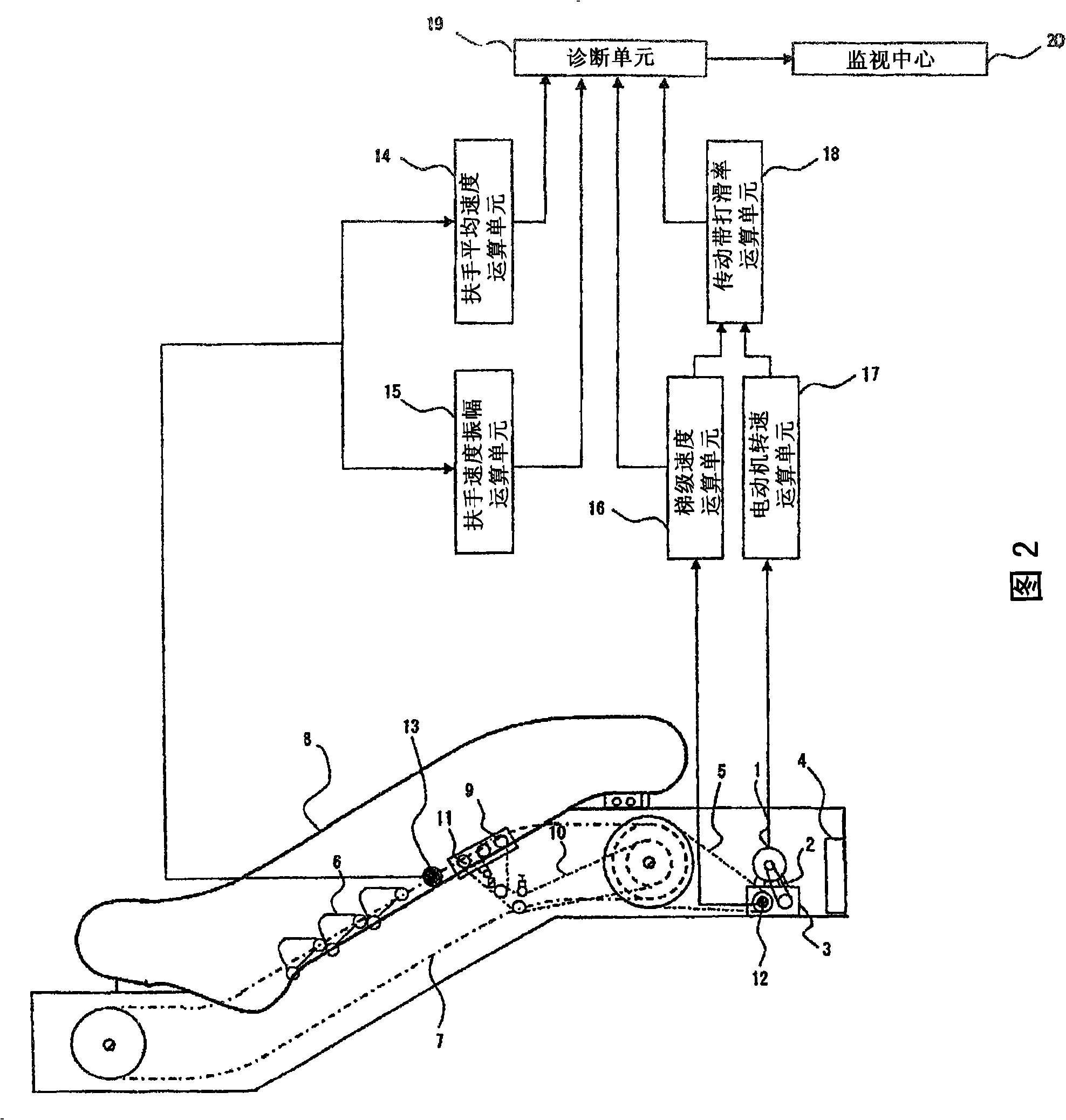

[0053] Fig. 2 is a functional block diagram showing, for example, a first embodiment of the handrail driving force monitoring device according to the present invention in the escalator shown in Fig. 1 .

[0054]As shown in Figure 2, in the first embodiment, there is a handrail average speed calculation unit 14 and a handrail speed amplitude calculation unit 15, wherein the handrail average speed calculation unit 14 is used to read the output signal of the handrail speed detector 13, to Count the total number of pulses output by the end of the predetermined distance walking, and divide the total number of pulses by the time required for walking to calculate the average speed V1 of the handrail 8 rotating one circle. The handrail speed amplitude calculation unit 15 uses V1 and read the same data, and generate the speed data of the handrail 8 according to the preset pulse number of each sample, and extract the minimum and maximum values of the generated speed data to calculate t...

no. 2 approach

[0068] Figure 7 It is a functional block diagram showing the second embodiment of the present invention. exist Figure 7 In the second embodiment shown, the following devices are added to the structure of the above-mentioned first embodiment.

[0069] In the second embodiment, considering that when there are many passengers, the average speed V1 of the handrail 8 may sometimes fluctuate due to reasons such as passengers holding the handrail, in order to approximate the diagnostic conditions, a calculation of the passenger load factor is provided. The unit 21 calculates the passenger load rate based on the information of the drive torque control device 4, so as to limit the reading of the output signals of the step speed detector 12 and the handrail speed detector 13 to the time when there are no passengers or few passengers.

[0070] In addition, it also has a reading judging unit 22 and an output signal storage unit 23, wherein the reading judging unit 22 stores and update...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com