Method for preparing fully-biodegradable agricultural film

A technology of biodegradable and agricultural film, which is applied in the field of preparation of fully biodegradable agricultural film, which can solve the problems of low softening point, insufficient complete degradability and timeliness of modified polylactic acid, and inability to meet mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below according to example the present invention is further described:

[0016] A preparation method for completely biodegradable agricultural film, comprising the following steps:

[0017] (1) Add polylactic acid and additives to the reaction tank in a mass ratio of 1:0.2 and mix them for modification. The components of the additives are glycerin, polylactic acid glycolic acid, and licorice. The ratio is 7:2:1;

[0018] The preparation method of the additive is as follows: after mixing glycerol, polylactic acid glycolic acid and licorice according to the above ratio, emulsification at a temperature of 60°C;

[0019] (2) Mix and stir the modified polylactic acid and the filler, and then produce completely biodegradable polylactic acid polymer particles through a granulator. The proportioning ratio of the polylactic acid and the filler is as follows: Lactic acid accounts for 40%, fillers account for 60%;

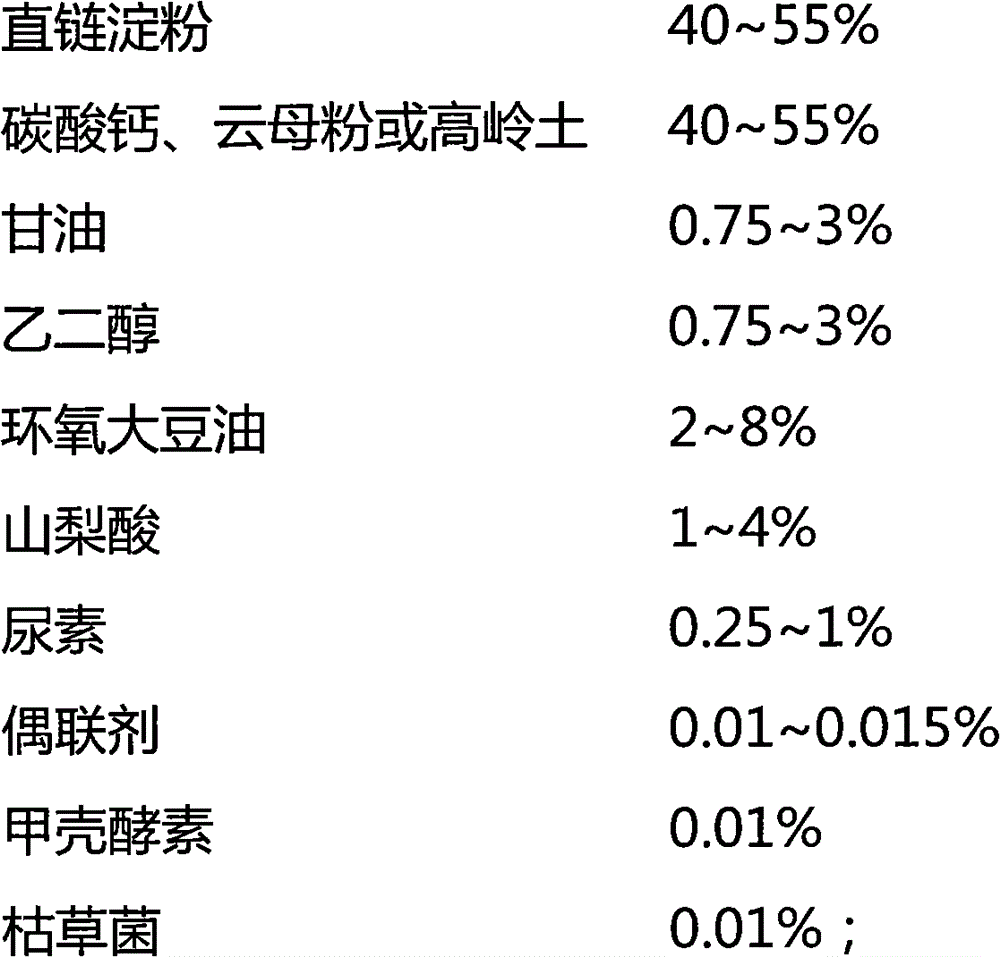

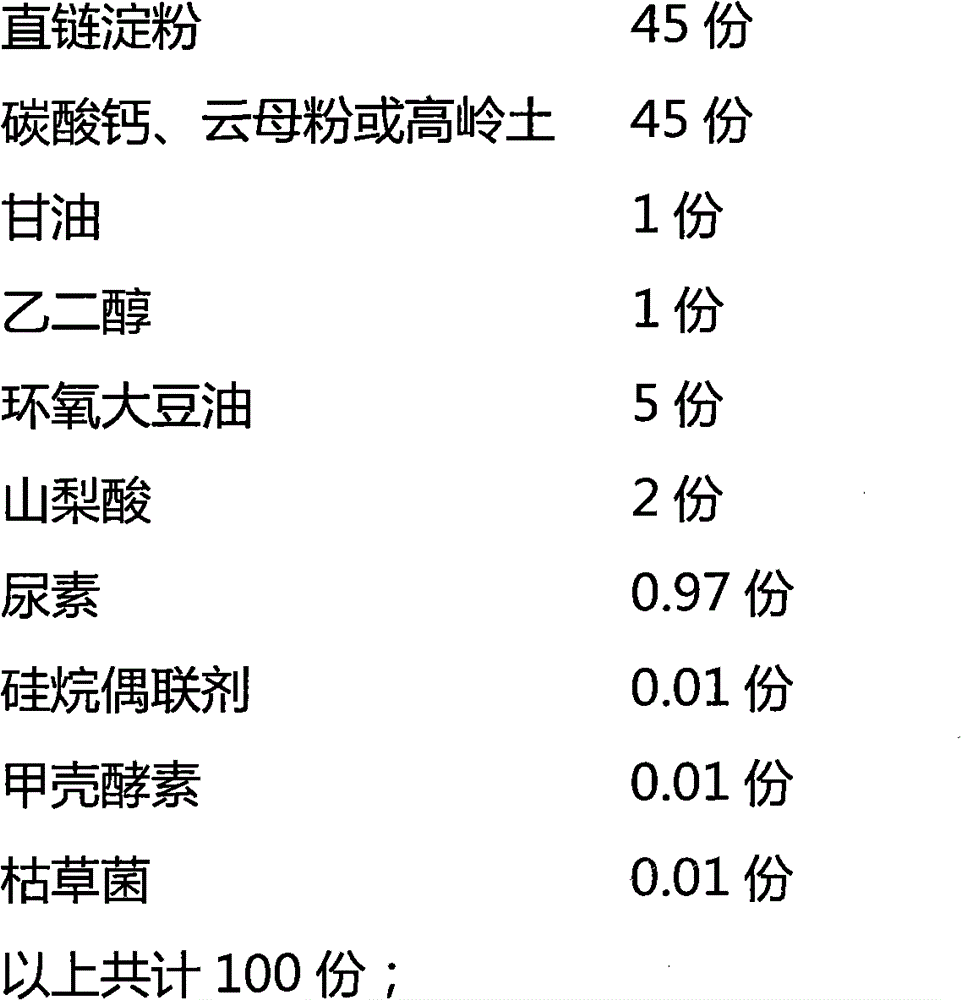

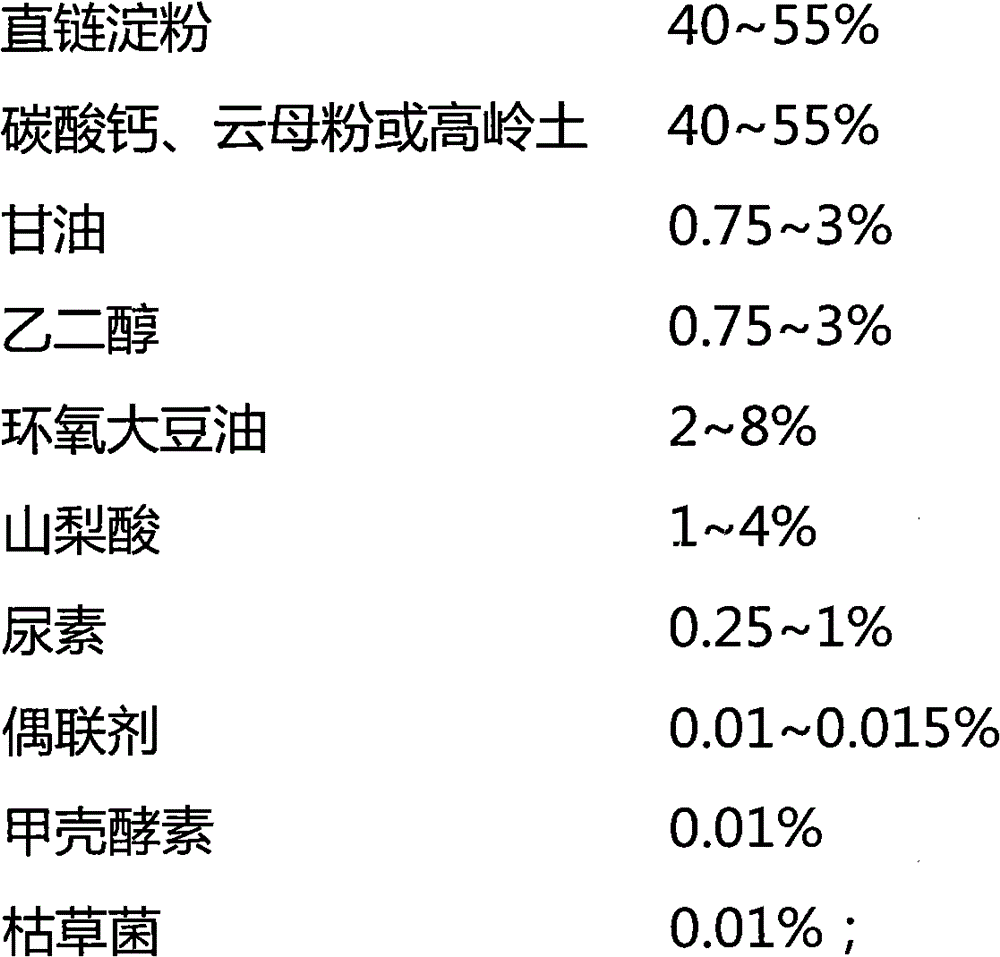

[0020] The specific composition and proportioning of described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com