Washing machine

A technology for washing machines and washing tanks, which is applied in the field of washing machines, can solve the problems of increased waste, complexity, and rising cost of materials and washing tank volumes, and achieve excellent water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

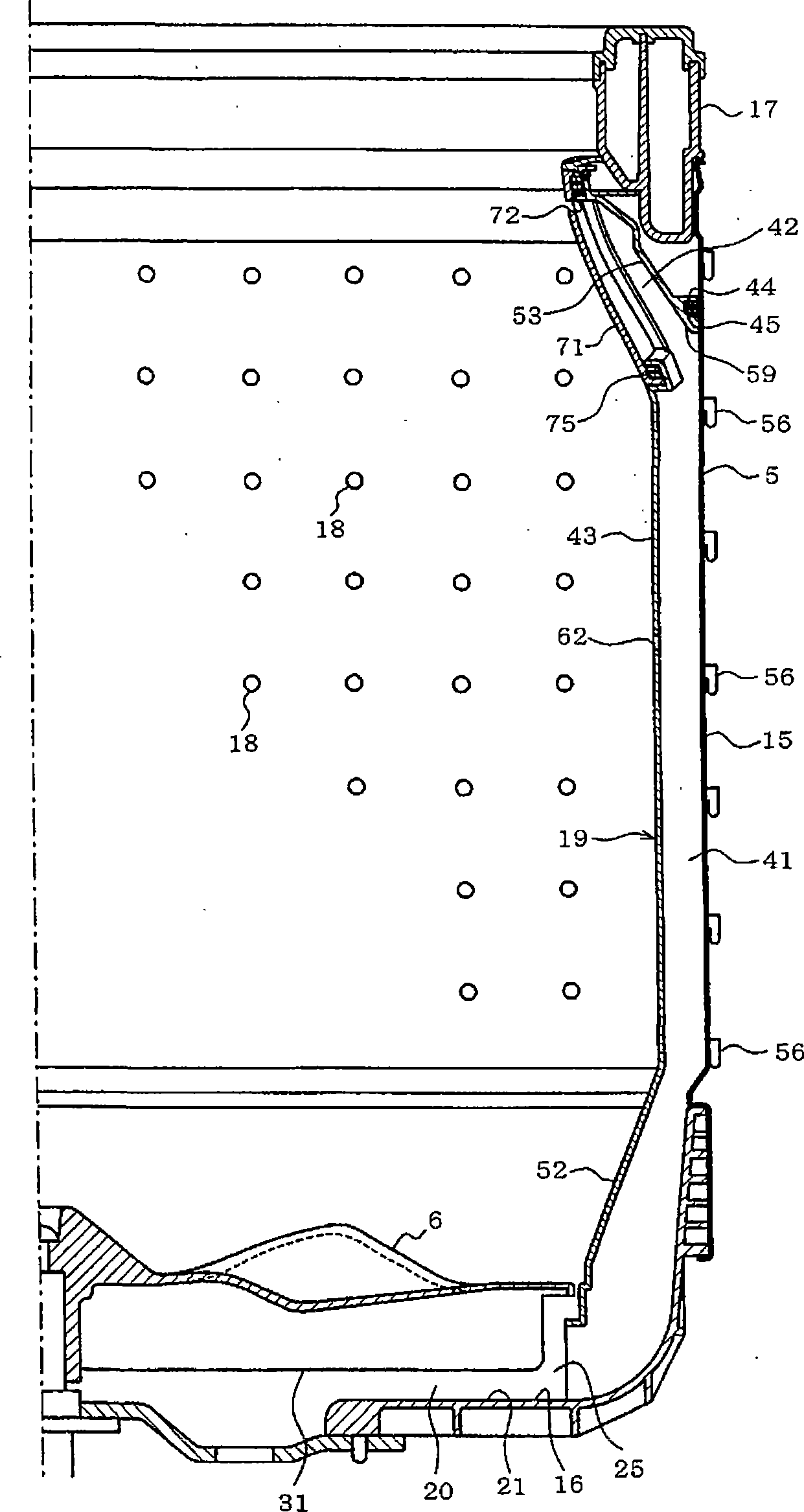

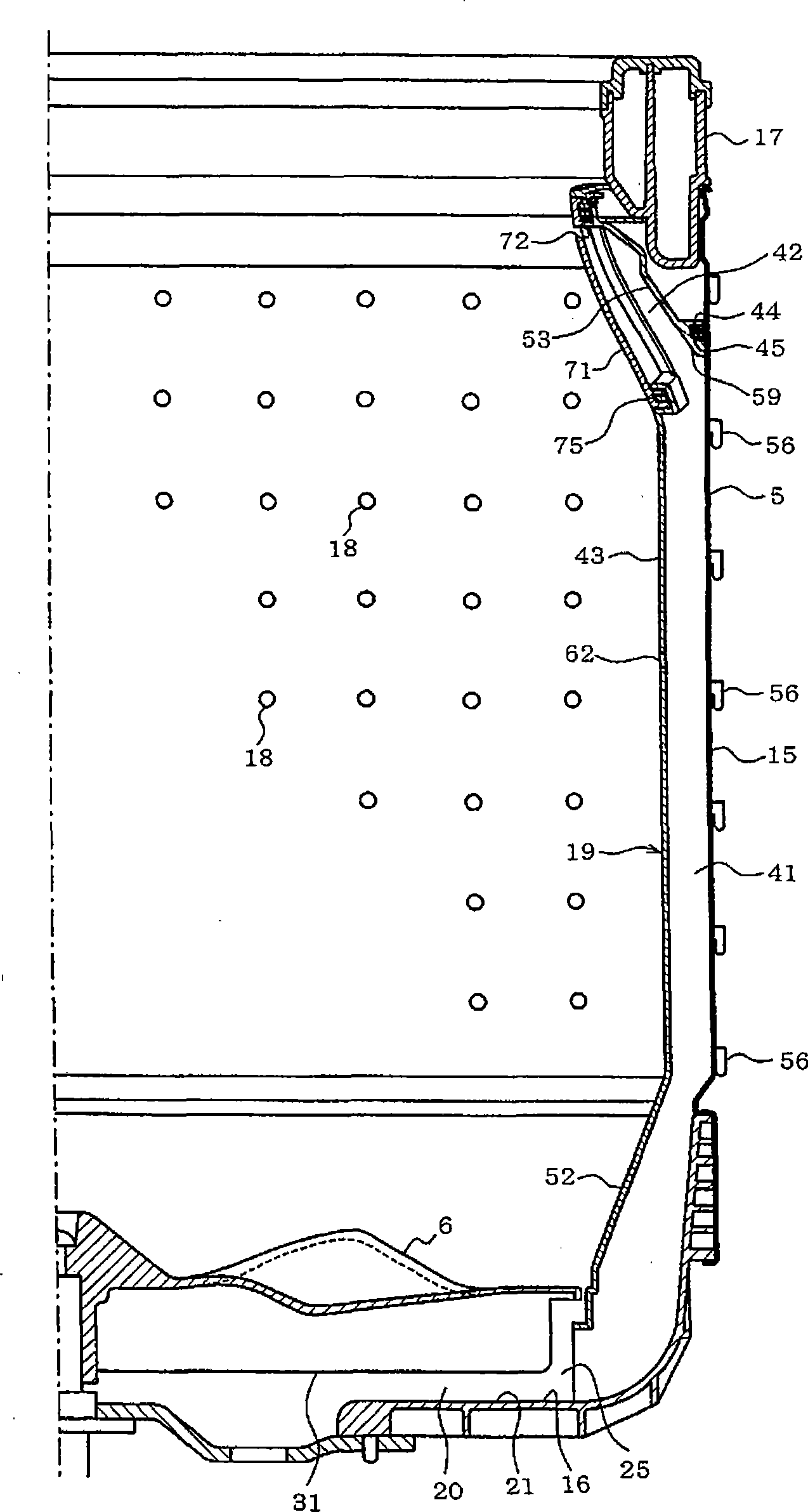

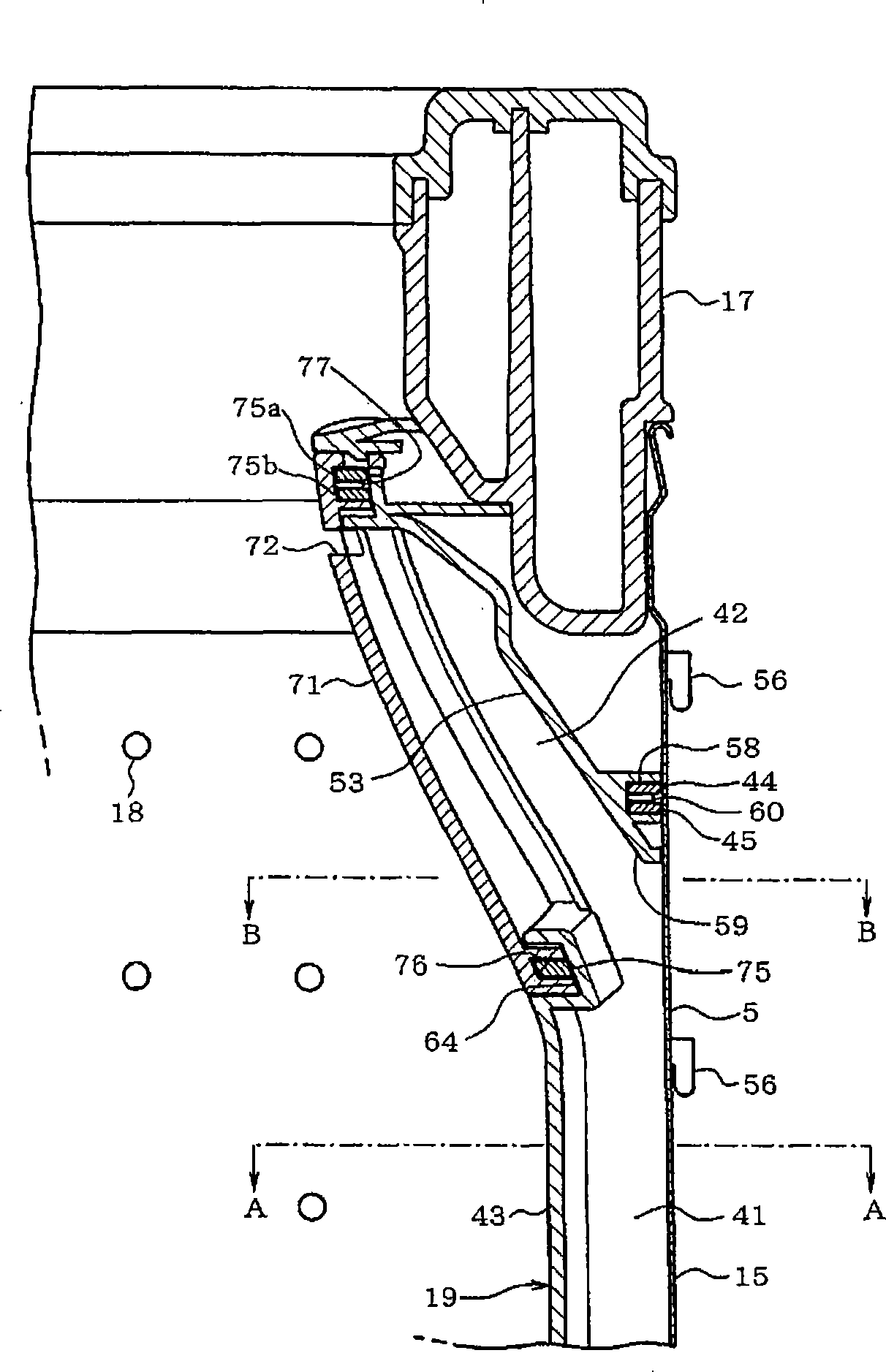

[0039] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0040] FIG. 3 schematically shows the overall configuration of the vertical washing machine (full automatic washing machine) 1 of the present embodiment. Here, inside the outer box 2 having a substantially rectangular shape, a water tank 3 for storing washing liquid is elastically supported by an elastic suspension mechanism 4. In the water tank 3, a vertical axis type washing tank 5 containing unillustrated laundry is provided, and an agitating body 6 is provided at the inner bottom of the washing tank 5. The above-mentioned washing tank 5 will be described later.

[0041] On the outer surface of the bottom of the water tank 3, a washing machine motor 7 as a rotation driving source is provided, and a mechanism 8 that transmits the rotation of the washing machine motor 7 and rotationally drives the washing tank 5 and the agitator 6 is also provided. At this time, the agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com