Dyeing silicon oil label, dyeing silicon oil and preparation method thereof

A production method and technology of silicone oil, applied in identification devices, instruments, seals, etc., can solve problems such as high error frequency, inconvenient quality inspection, and low efficiency, and achieve the effects of increasing process difficulty, preventing counterfeit products, and reducing error frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

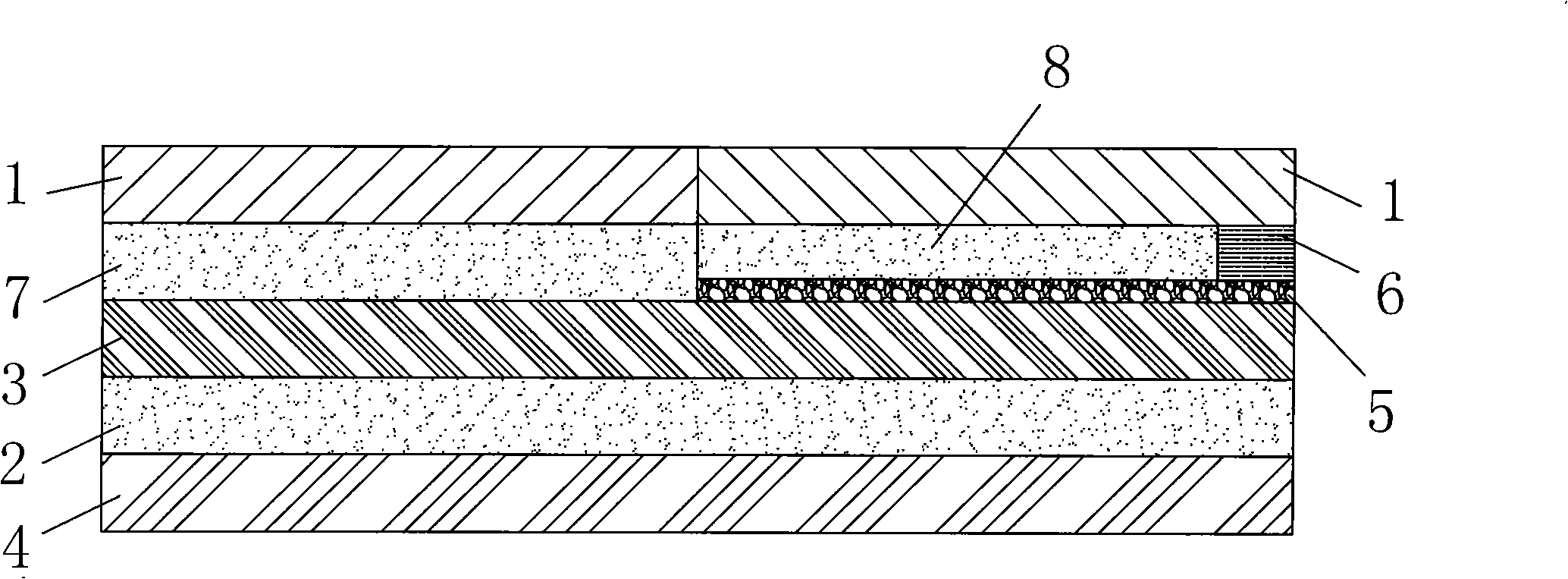

[0021] figure 1 It shows the cross-sectional structure of a preferred embodiment of the dyed silicone oil label of the present invention. The dyed silicone oil label includes sequentially stacked backing paper 4, the first adhesive layer 2, spacer paper 3 and a surface material with information - thermal paper1. However, between the spacer paper 3 and the thermal paper 1, a second adhesive layer 7 is provided on the left side, and a dyed silicone oil layer 5 and a third adhesive layer 8 are stacked on the adjacent right side, adjacent to the third adhesive layer. The outer side of the layer is also provided with a layer 6 of white ink. figure 1 The heat-sensitive paper 1 on the upper right side on the dyed silicone oil layer 5 can be easily torn off and attached to the product along with the production steps of the product. The white silicone oil 6 on the bottom of the right side can separate the thermal paper from the spacer paper, making it easy to tear off. Under the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com