Systen and method for position control of a mechanical piston in a pump

A technology of pumping system and control scheme, applied in pump control, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of fluid pressure accumulation, damage to fluid, change physical characteristics of fluid, etc., to improve distribution performance and working ability , precise and repeatable position control, improve the effect of speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings, which are not necessarily drawn to scale and in which like reference numerals are used to designate like and corresponding parts throughout the various drawings.

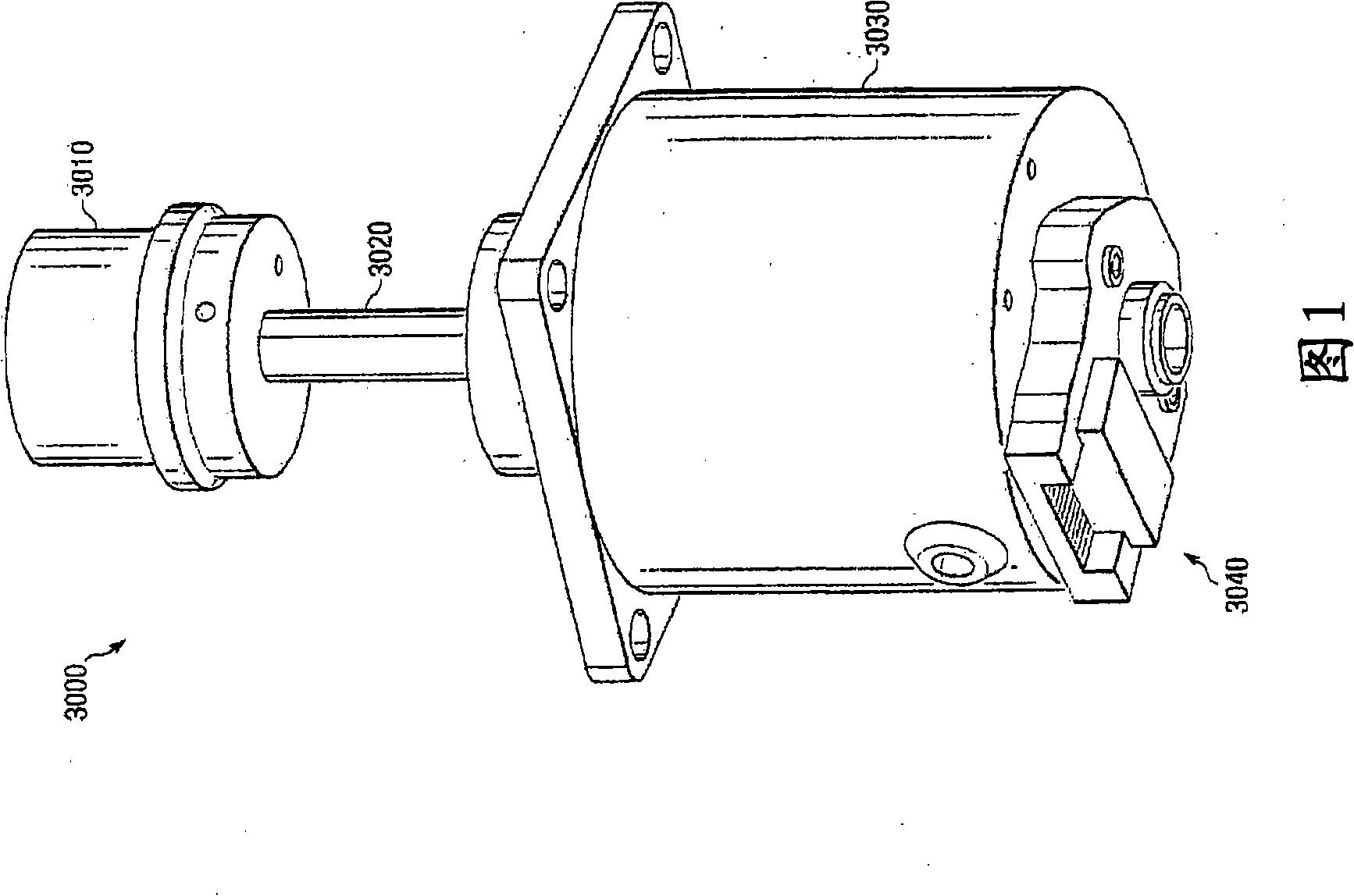

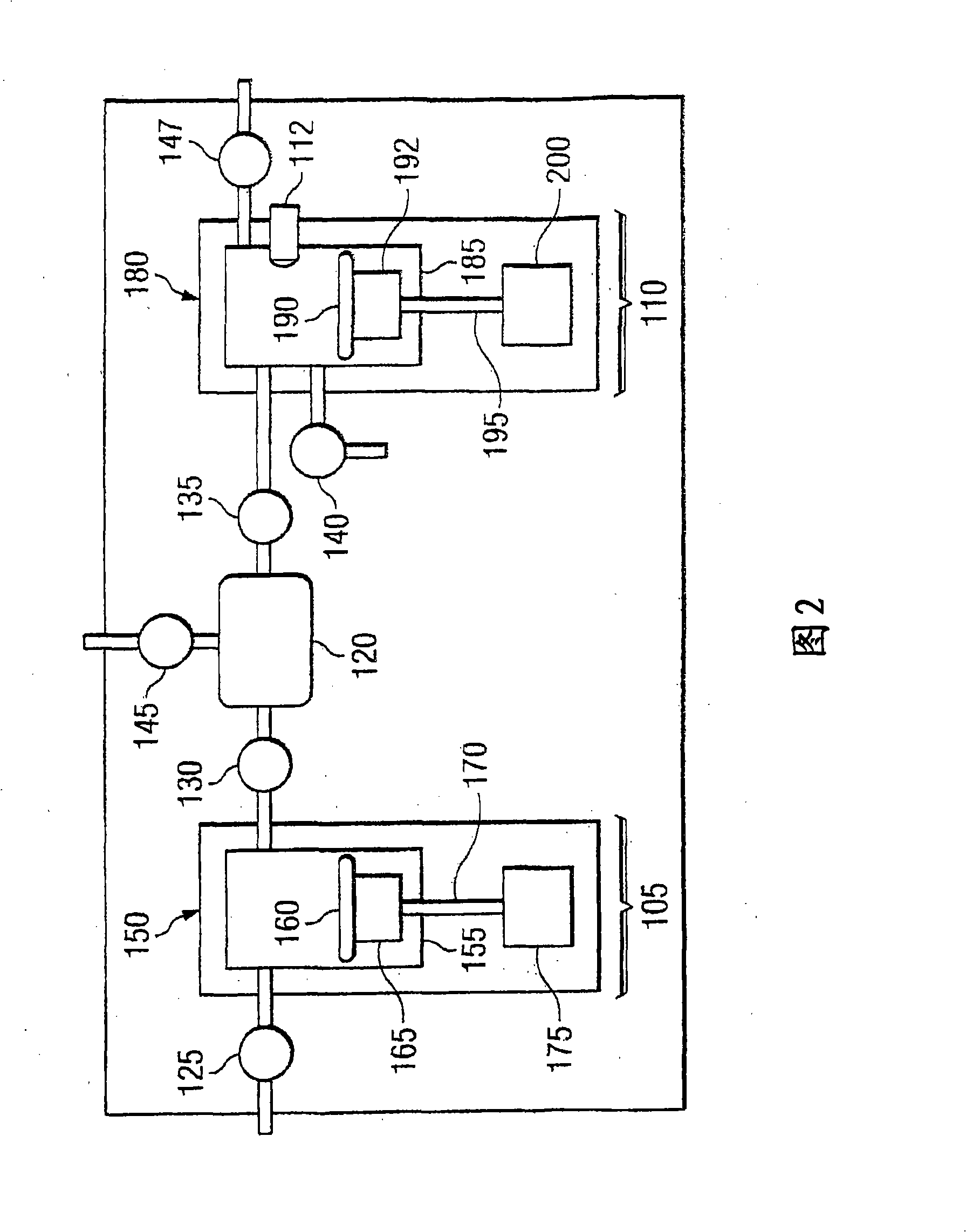

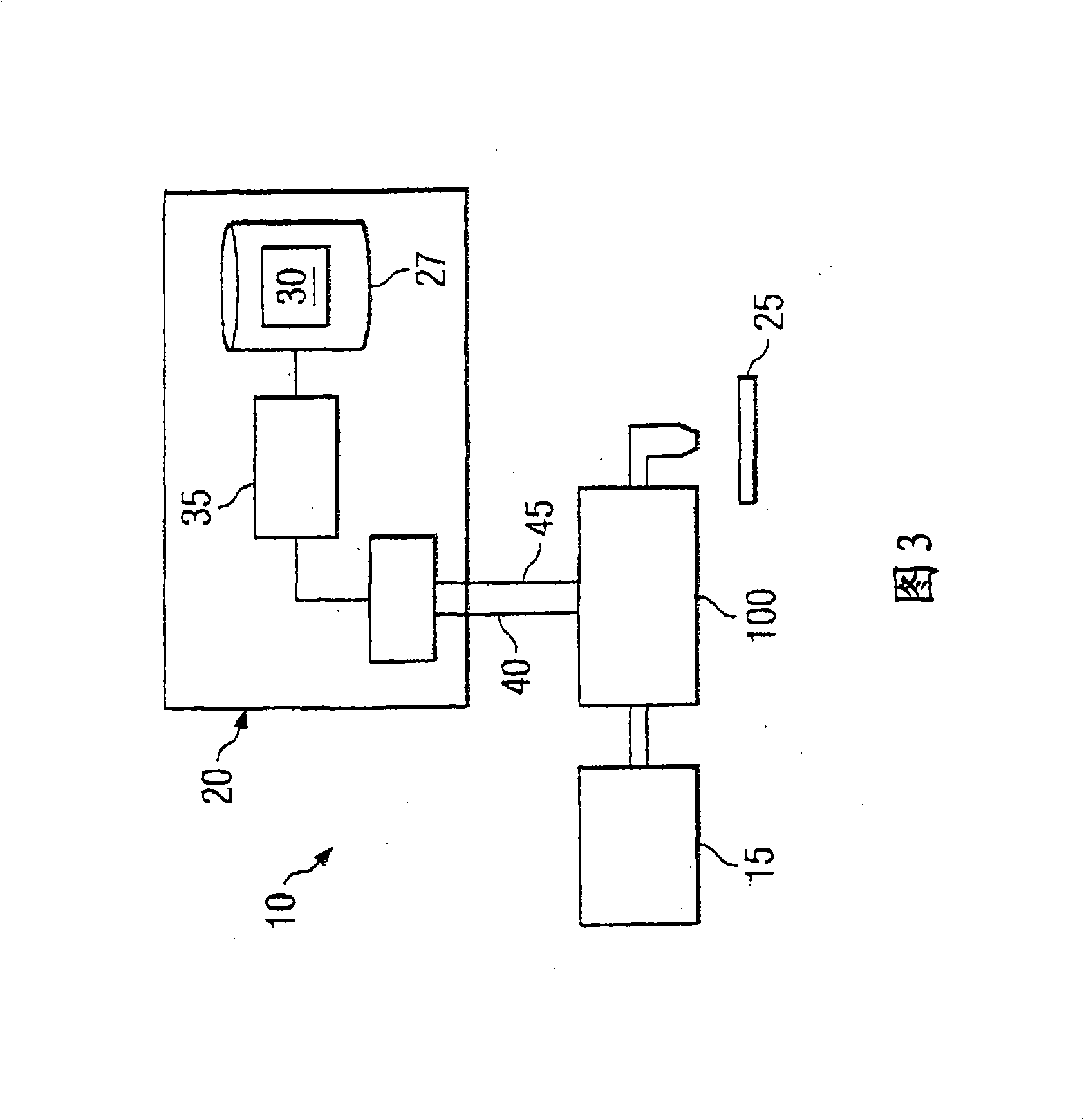

[0028] Embodiments of the present invention relate to pumping systems having multiple stages ("multi-stages") of pumps for supplying and dispensing fluids onto wafers during semiconductor manufacturing processes. Specifically, an embodiment of the present invention provides a pumping system using a multi-stage pump, which includes: a supply-stage pump driven by a stepping motor; and a distribution-stage pump driven by an Driven by a brushed DC motor for extremely precise and repeatable control of fluid movement and the amount of fluid dispensed on the wafer. It should be appreciated that multistage pumps and pumping systems using such pumps as described herein are provided by way of example, not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com