Manufacturing method of combined frame and stamping device thereof

A combined frame and stamping equipment technology, which is applied to other manufacturing equipment/tools, manufacturing tools, welding equipment, etc., can solve the problems of high material cost and low utilization, and achieve the effect of rapid output and easy alignment and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

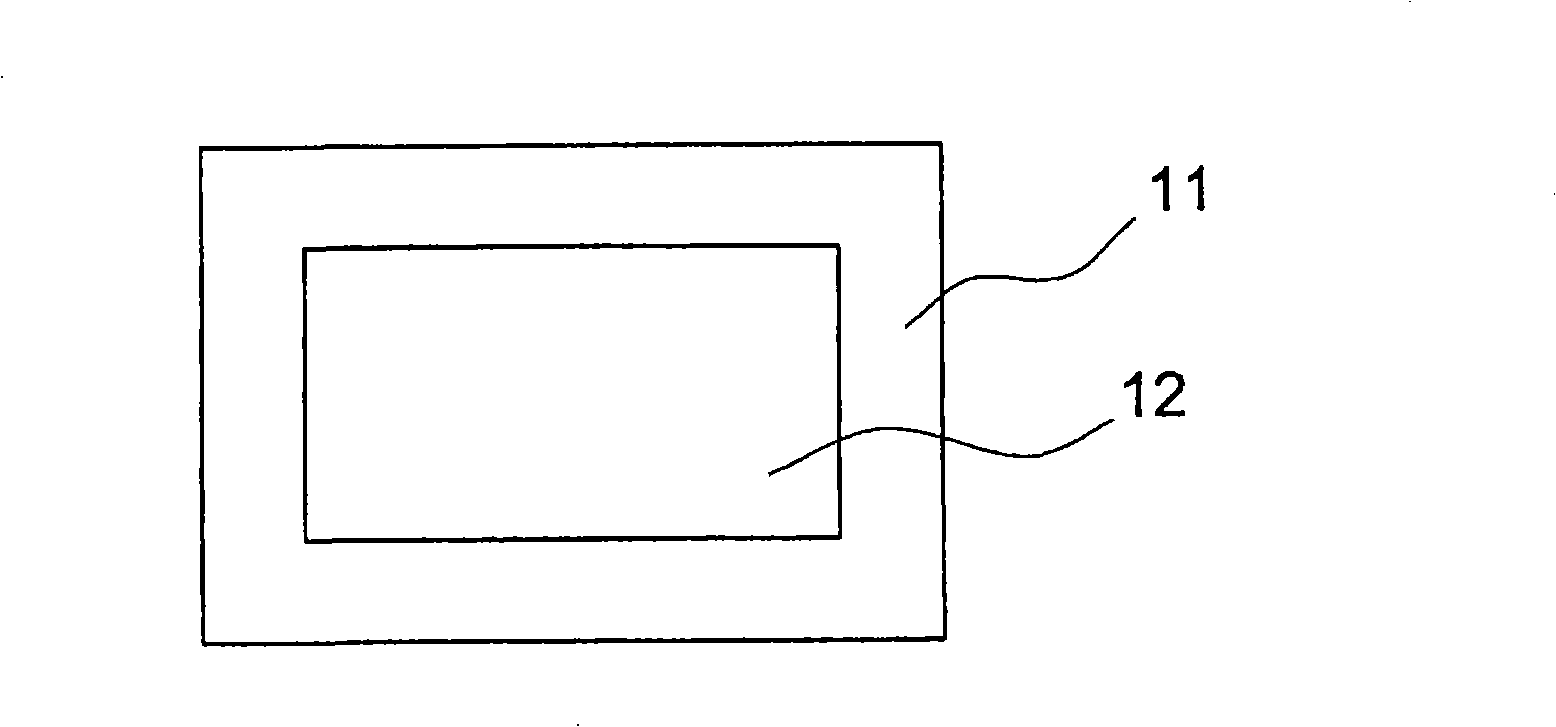

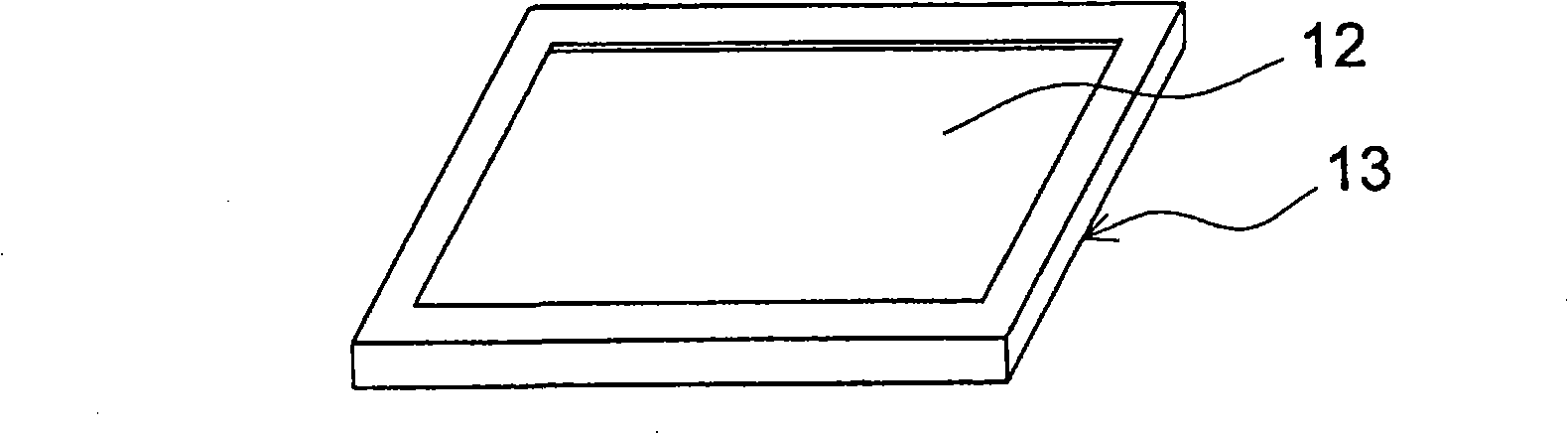

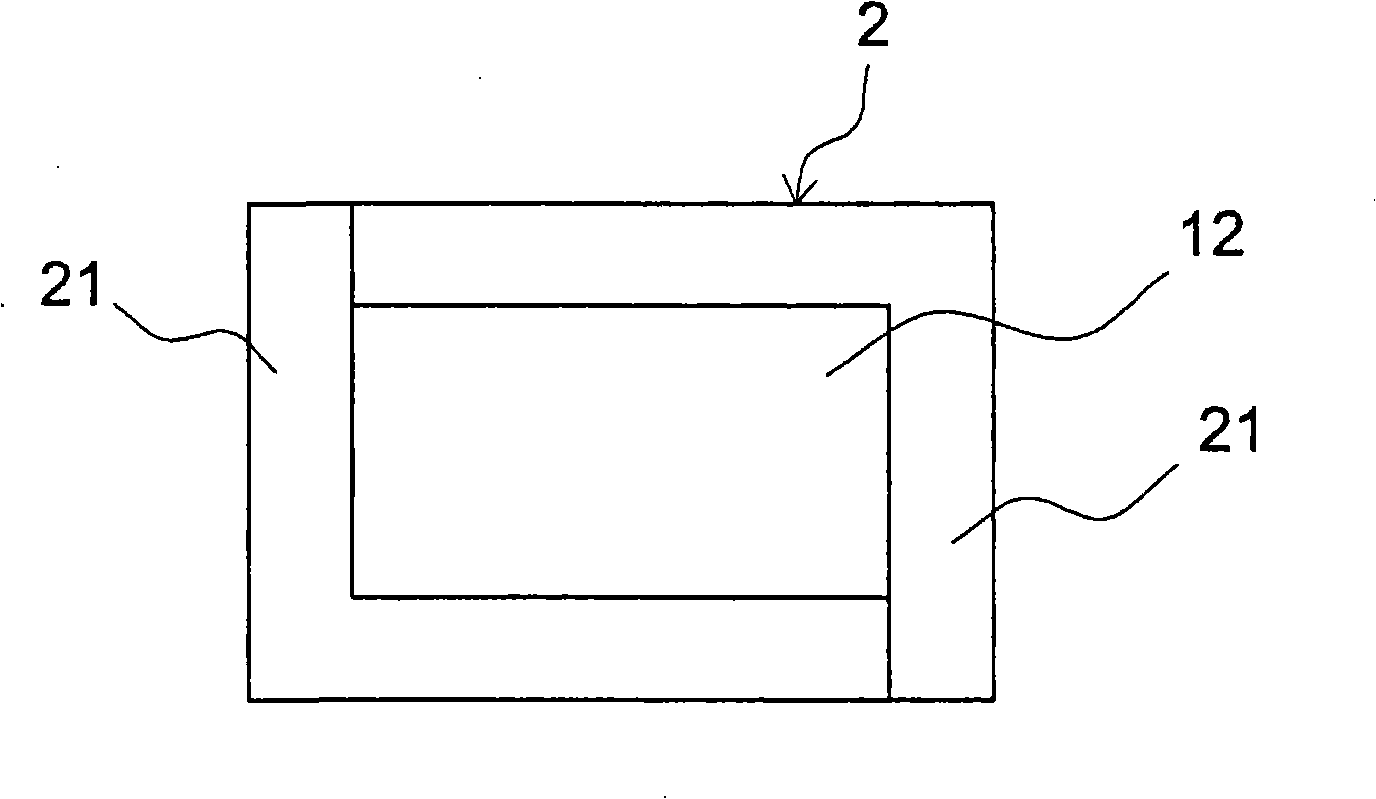

[0039] Please refer to Figure 4a , which illustrates a stamping device for manufacturing a combined frame according to a preferred embodiment of the present invention, the manufactured combined frame is applied to a flat-panel display, and the flat-panel display is a liquid crystal display or a plasma display. Such as Figure 4a As shown, the stamping equipment for manufacturing a combined frame of the present invention includes a stamping unit 41 and a welding unit 42 . The stamping unit 41 has a stamping table 411, and a plurality of stamping materials 5, 5' can be transported to the stamping table 411 for alignment and combination. The welding unit 42 is arranged on the periphery of the stamping table 411, and is used for welding the stamping materials 5, 5' after alignment. The welding unit 42 is an electric welding machine or a laser welding machine.

[0040] Please refer to Figure 4b , taking the preparation of a rectangular frame 53 formed by butting two L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com