Heating equipment and process for noble metal stock path

A heating device, electric heating device technology, applied in the direction of feeding trough, glass production, etc., can solve the problems that cannot meet the production requirements of precious metal material channel, overflow of molding machine, and cannot produce normally, so as to reduce energy consumption and meet production requirements. Demand, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

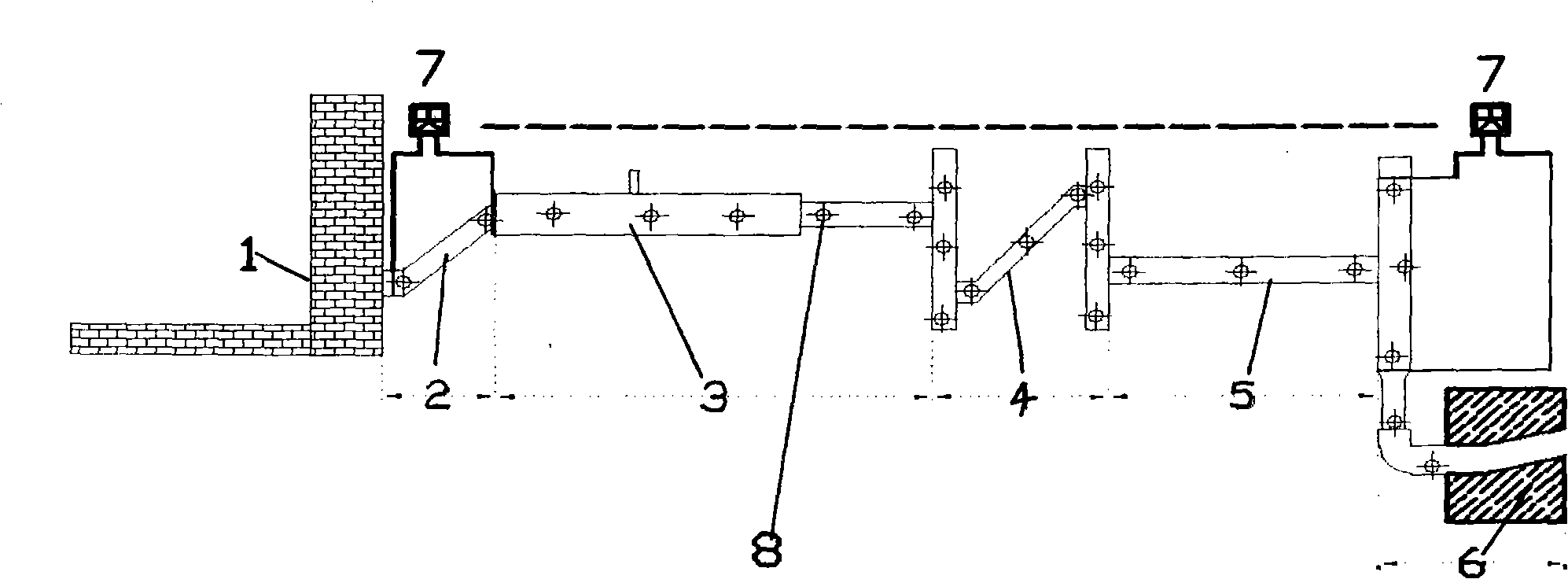

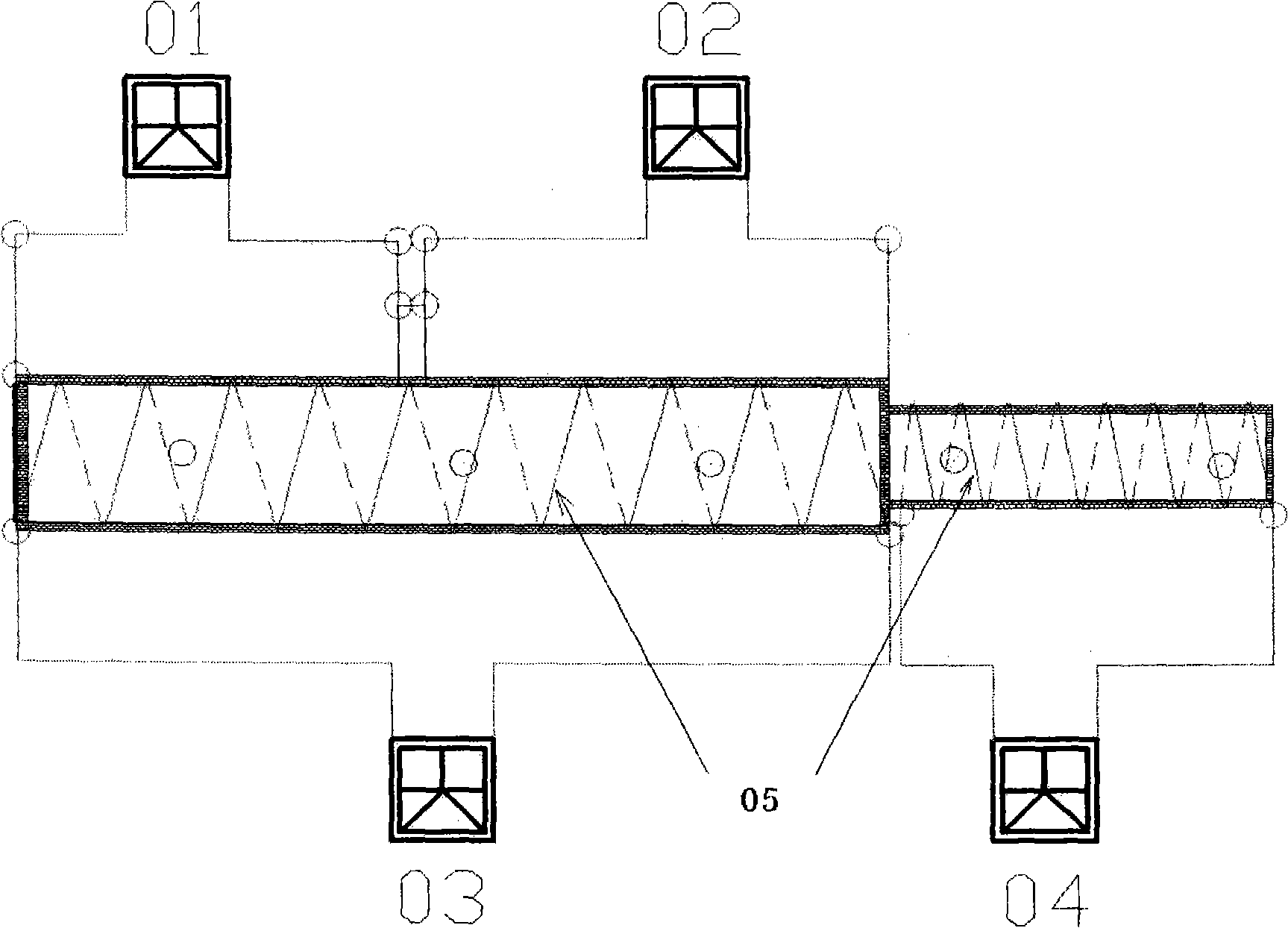

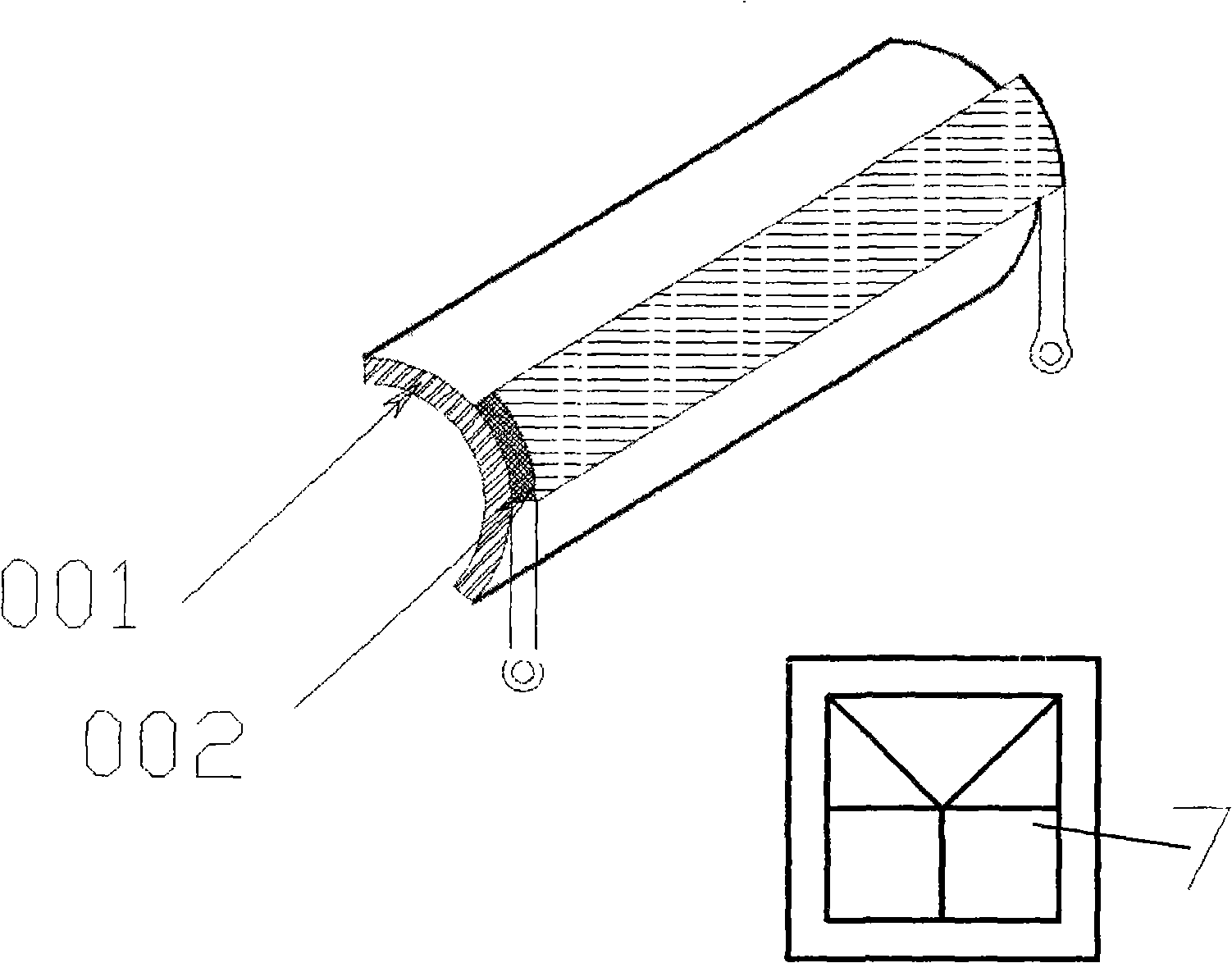

[0033] Combine below figure 1 , 2 , 3 illustrates the implementation method of the present invention.

[0034] A heating device for a precious metal forehearth, comprising a molten glass lifting zone 2 connected to a melting pool 1, a clarification zone 3 connected to the lifting zone 2, a stirring zone 4 connected to the clarifying zone 3, The cooling zone 5 connected with the stirring zone 4, the feeding zone 6 connected with the cooling zone 5, the heating control unit 7 responsible for heating each zone and the measuring device 8 for measuring the temperature in each zone are characterized in that:

[0035] In the stirring zone 4, a direct electric heating device is provided, and the direct electric heating device is a heating control unit 7 with direct current low voltage and high current directly connected to the noble metal tube wall,

[0036] An indirect electric heating device is provided in the cooling zone 5 and the feeding zone 6. The indirect electric heating de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com