Directly-down back light module unit and LCD using the directly-down back light module unit

A liquid crystal display and backlight module technology, applied in static indicators, optics, instruments, etc., can solve problems such as uneven brightness, poor reliability of backlight modules, etc., to improve uniformity, improve display quality, and good reliability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

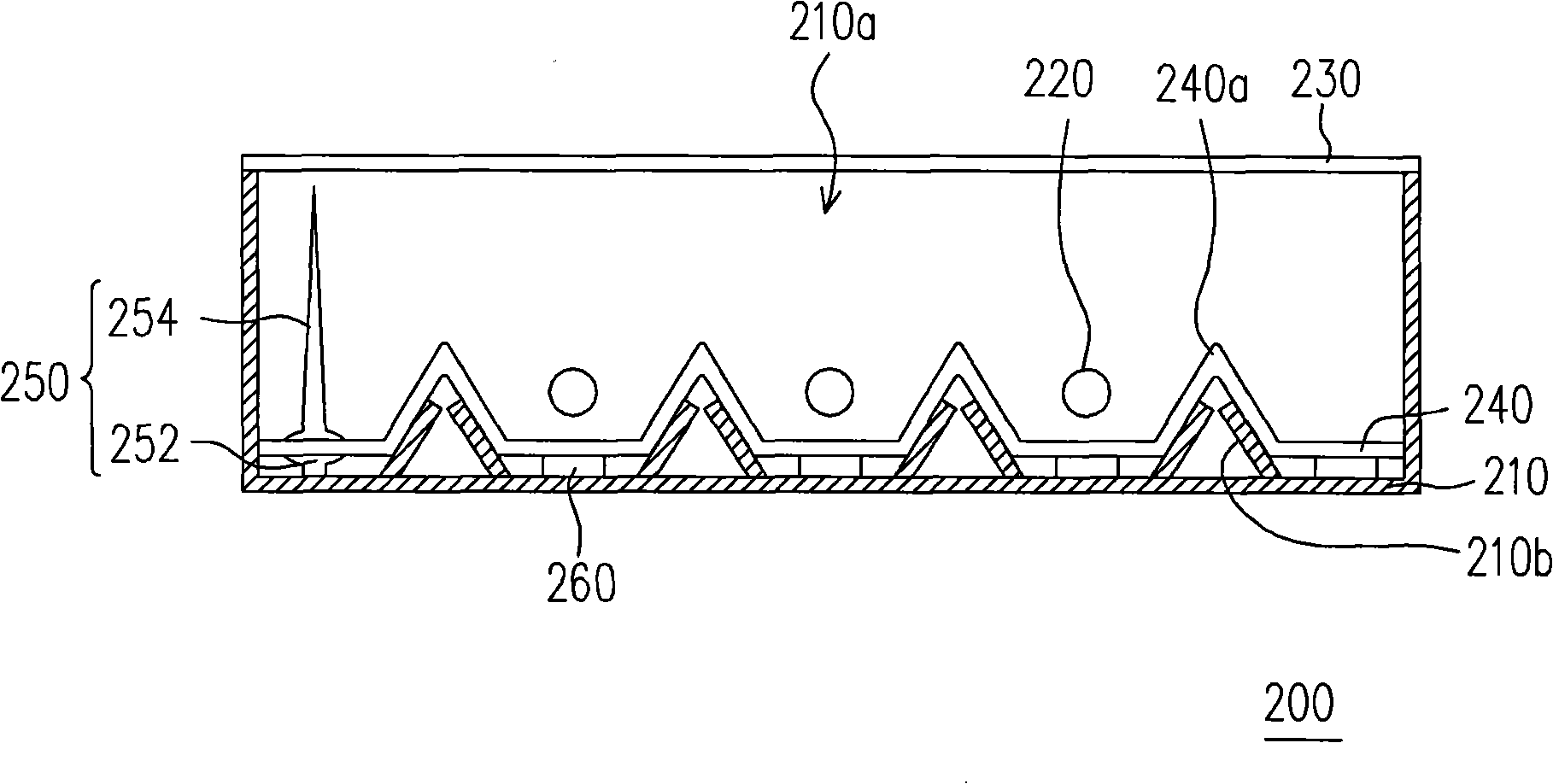

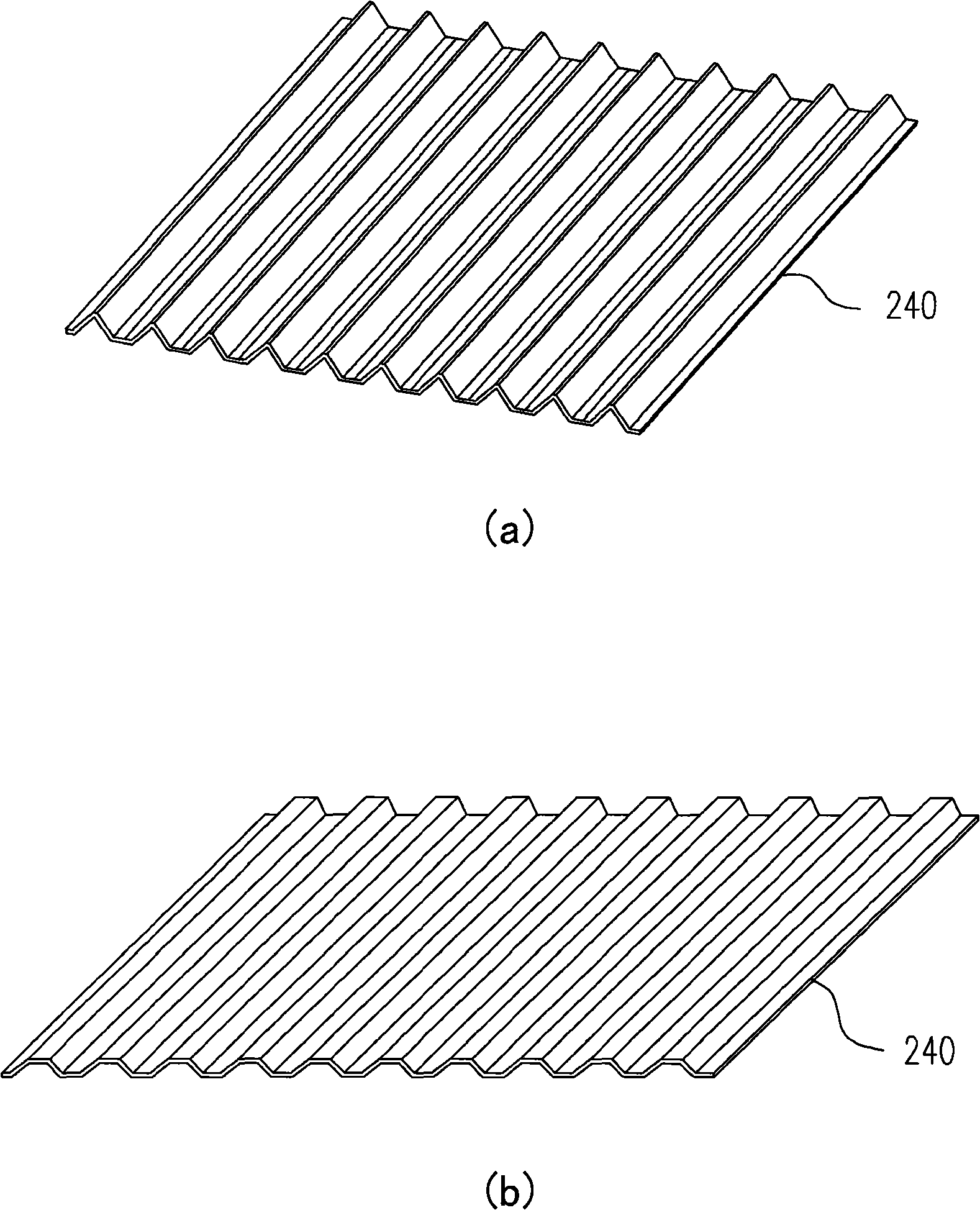

[0061] figure 2 It is a schematic cross-sectional view of a direct type backlight module according to the first embodiment of the present invention. Please refer to figure 2 , The direct type backlight module 200 of the present invention includes a light box 210, a plurality of light sources 220, an optical film set 230, a shape reflector 240 and a plurality of positioning parts 210b. Wherein, the light box 210 has an opening 210a, and the light source 220 is disposed in the light box 210, and the optical film group 230 is disposed at the opening 210a.

[0062]Generally speaking, the optical film set 230 may include at least one of a diffuser film (Diffuser film), a Brightness enhanced film (BEF) and a prism sheet (Prism sheet). The light is scattered more evenly, and the brightness enhancement film can enhance the brightness displayed by the direct type backlight module 200 . In addition, the prism sheet can improve the correctness of the outgoing light direction. The d...

no. 2 example

[0071] This embodiment is very similar to the first embodiment, and the main difference between the two is that: the direct type backlight module of this embodiment uses a positioning member to fix the shaped reflective sheet instead of a positioning pin. Figure 5 is a schematic diagram of the direct type backlight module according to the second embodiment. Please refer to Figure 5 , The direct-lit backlight module 300 of the present invention includes a light box 210 , a plurality of light sources 220 , an optical film set 230 and a shaped reflector 240 . Wherein, the light box 211 has an opening 211 a, and the light source 220 is disposed in the light box 211 .

[0072] In addition, the optical film set 230 is disposed at the opening 211 a, and the shaped reflective sheet 240 is disposed between the light source 220 and the bottom of the light box 211 . The above-mentioned shaped reflective sheet 240 has a plurality of reflective slopes 240a, and the light source 220 is ...

no. 3 example

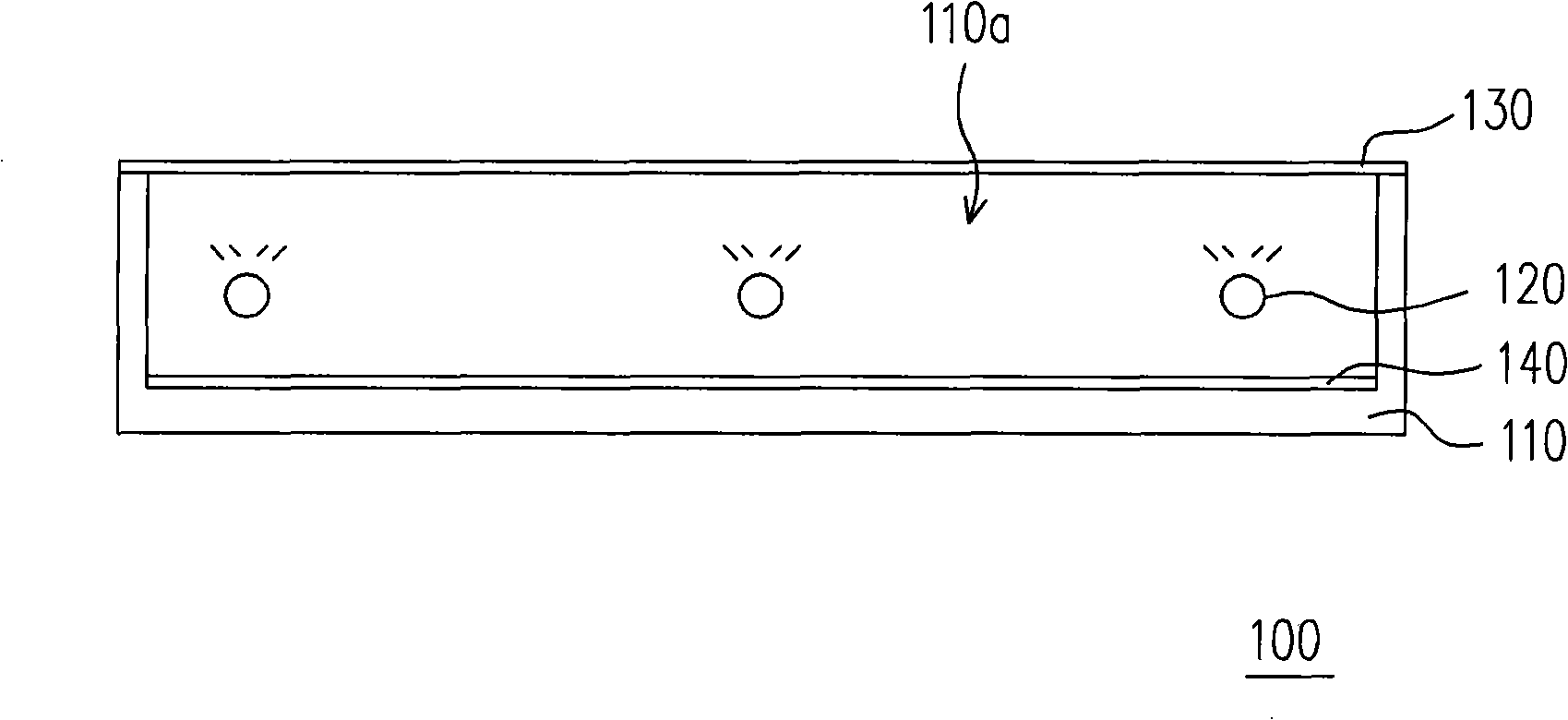

[0074] FIG. 6 is a schematic diagram of a liquid crystal display according to a third embodiment of the present invention. Please refer to FIG. 6 , the liquid crystal display 500 of the present invention includes the above-mentioned direct type backlight module 200 and a liquid crystal display panel 400 . Wherein, the structure of the direct-type backlight module 200 has been clearly disclosed in the first embodiment, and the liquid crystal display panel 400 is disposed beside the direct-type backlight module 200 corresponding to the opening 210 a of the light box 210 .

[0075] Please refer to Figure 7 , the liquid crystal display panel 400 of the present invention can also be combined with the direct type backlight module 300 to form a liquid crystal display 600 . Wherein, the structure of the backlight module 300 has been clearly disclosed in the second embodiment, and the liquid crystal display panel 400 is disposed beside the direct-type backlight module 300 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com