Pixel construction and thin-film transistor thereof

A technology of thin-film transistors and semiconductors, which is applied in the direction of transistors, electric solid-state devices, semiconductor devices, etc., and can solve problems such as inconsistent feed-through voltages of thin-film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

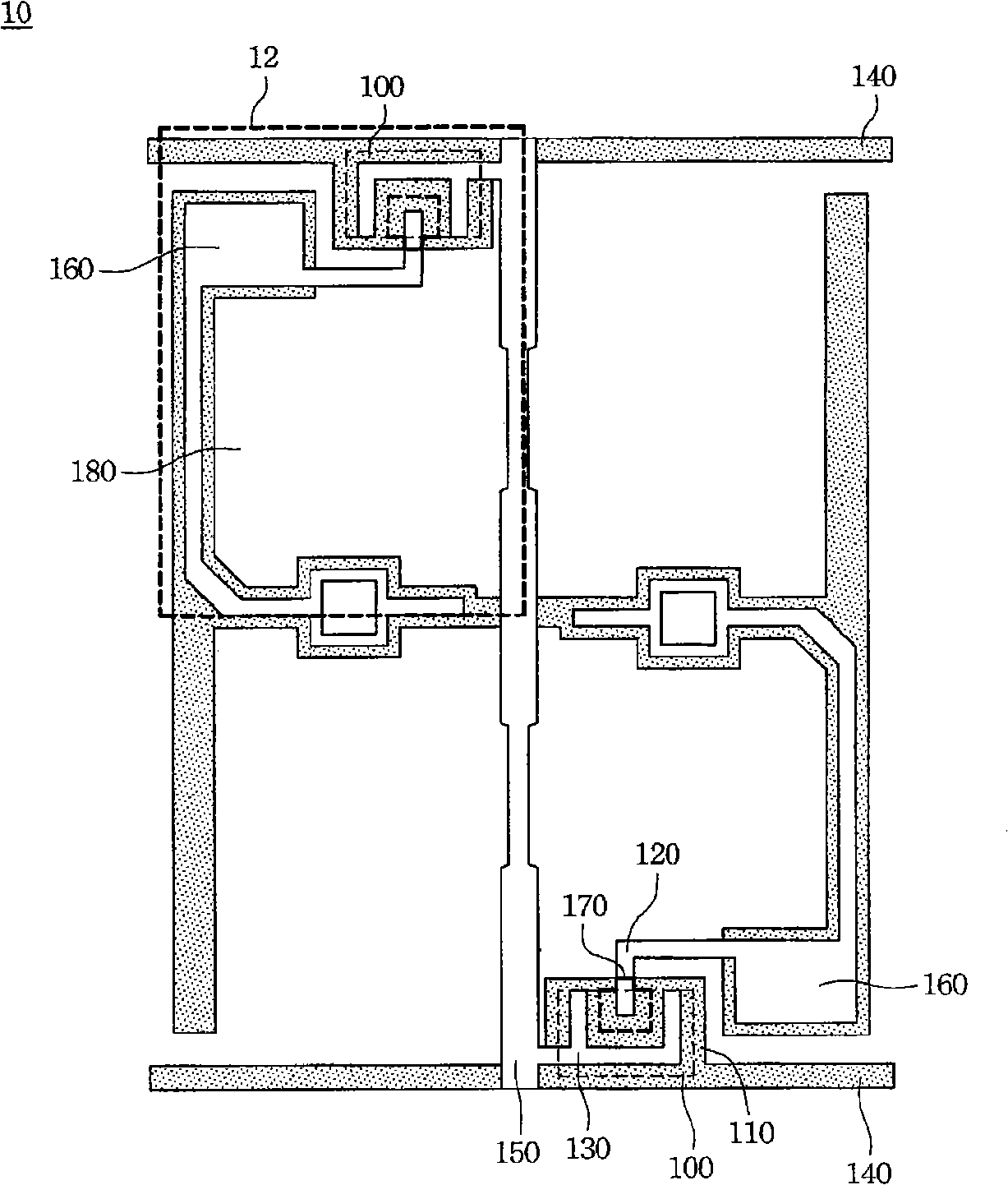

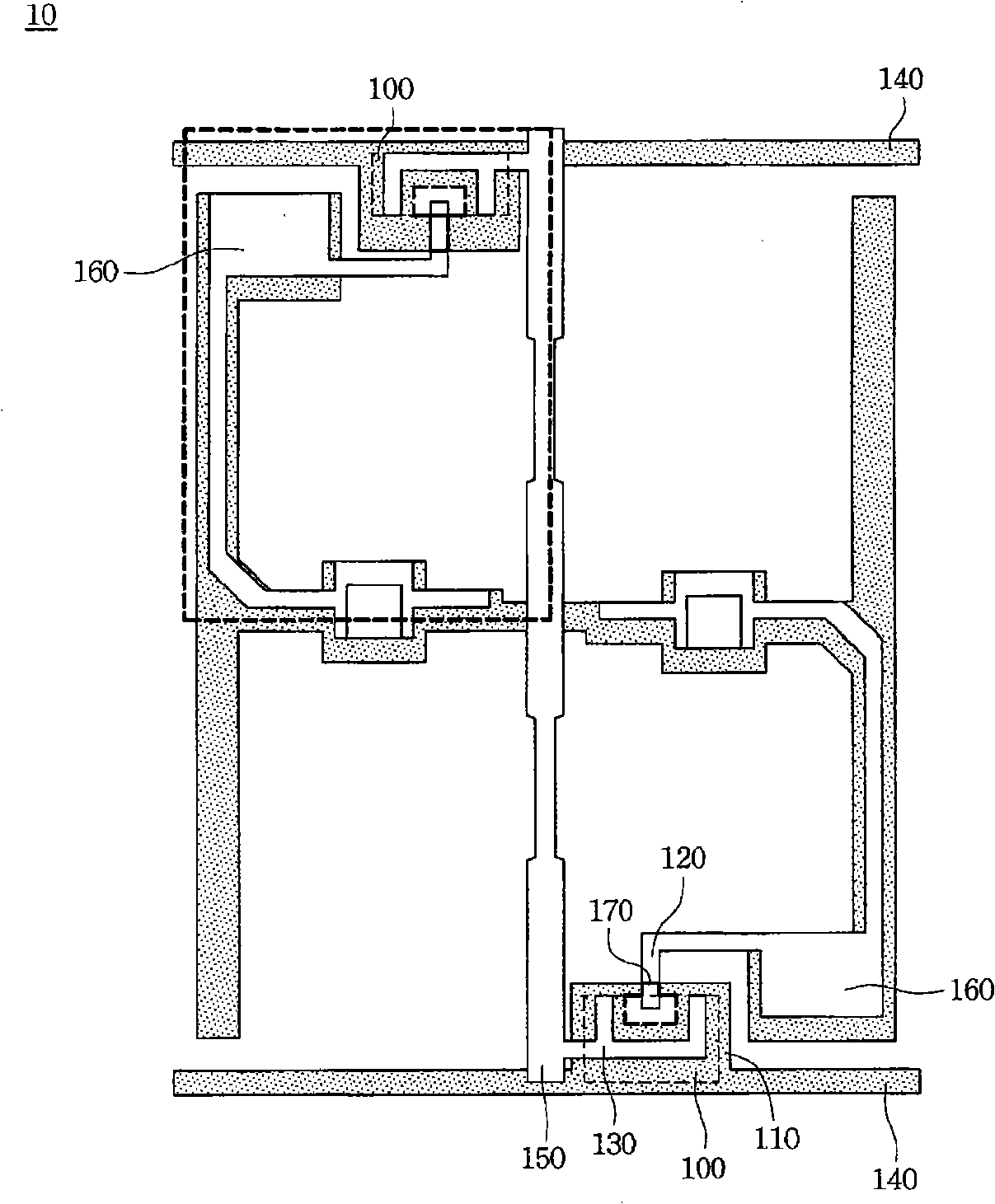

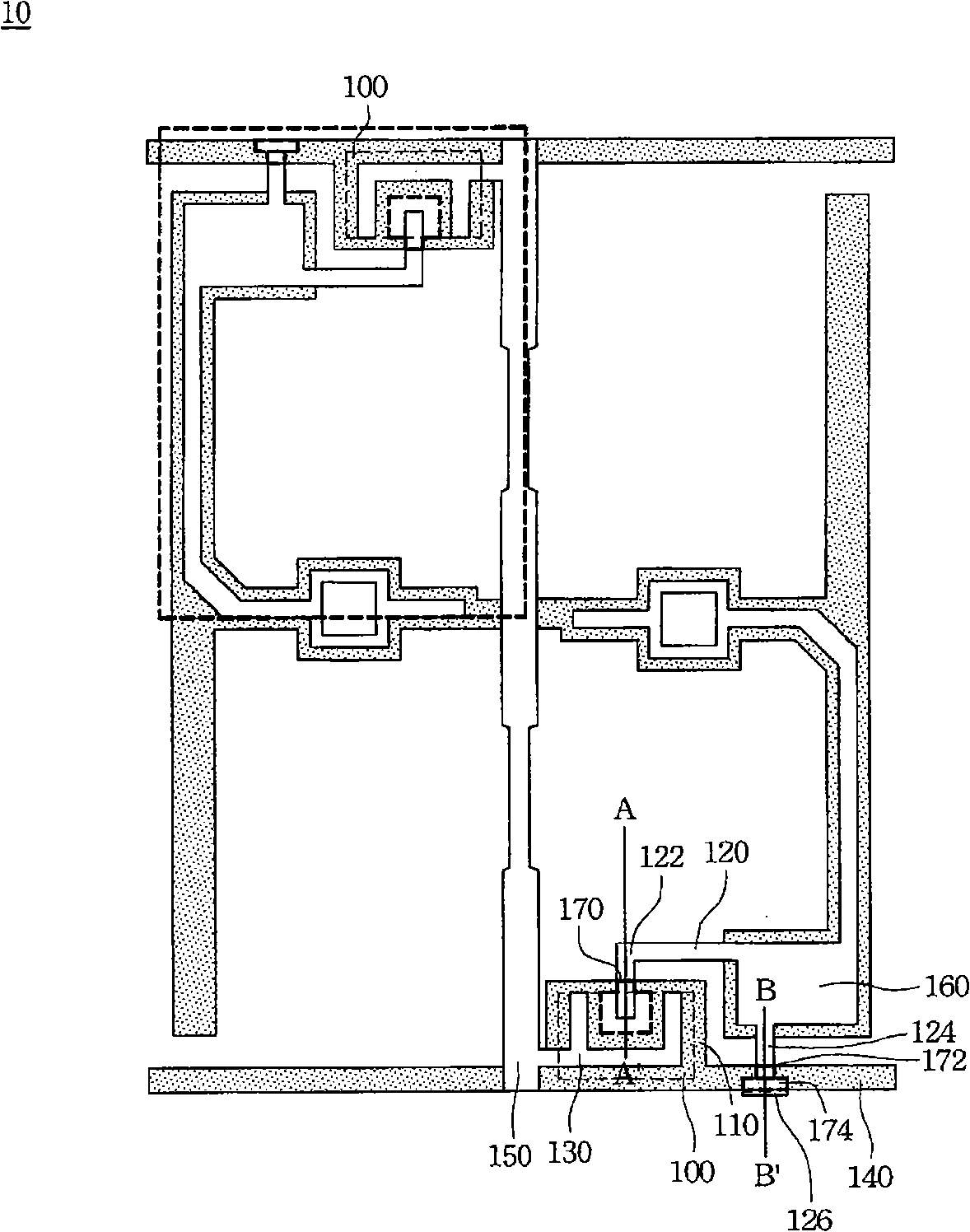

[0051] Please refer to Figure 2A , which shows a top view of the pixel structure 10 according to an embodiment of the present invention. The pixel structure 10 mainly has several thin film transistors 100 arranged in an array. Each TFT 100 has a gate 110 , a drain 120 and a source 130 , wherein the gate 110 is electrically connected to the scan line 140 , and the source 130 is electrically connected to the data line 150 .

[0052] Please also refer to Figure 2A to Figure 2C . Figure 2B show according to Figure 2A An enlarged cross-sectional view of the line AA' shown in , Figure 2C show according to Figure 2A An enlarged cross-sectional view of the BB' connection shown in .

[0053]Taking the bottom gate structure as an example, the gate 110 and the scan line 140 are both disposed on the substrate 200 . An insulating layer 210 is adjacent to cover the gate 110 and the scan line 140 . Next, a semiconductor layer 220 is covered on the insulating layer 210 . A drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com