Top and guilder two-in-one tunnel boring machine

A tunnel boring machine and tunnel boring technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of increasing the cost of tunnel construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

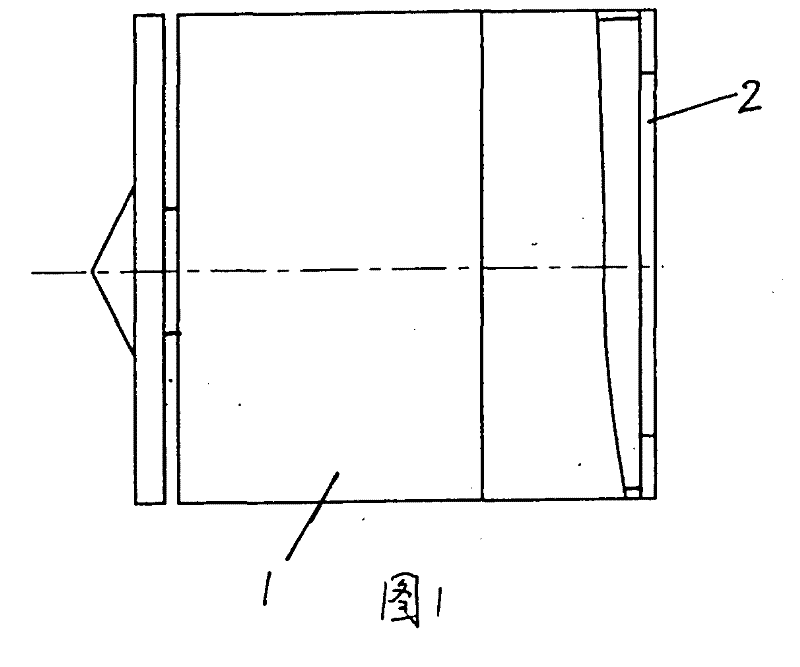

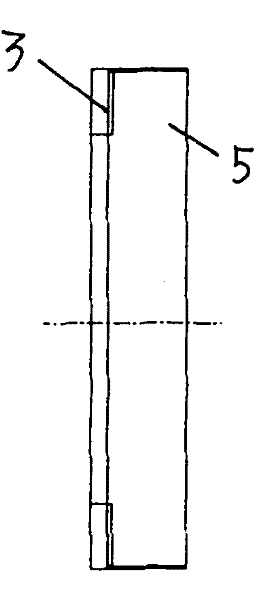

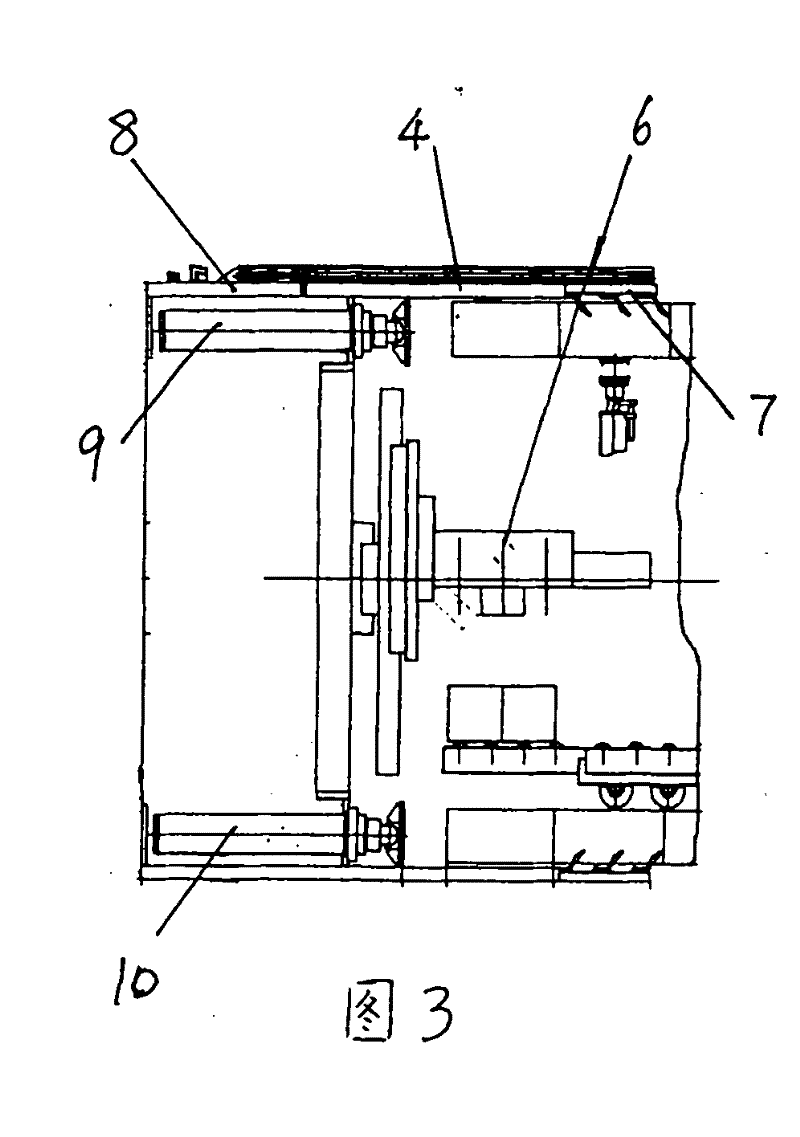

[0008] The figure includes a tunnel boring machine head 1, which is characterized in that there is a connecting end 2 on the rear end surface of the tunnel boring machine head 1, and a jacked pipe joint socket device 3 or a shield assembly device 4 connected with the connecting end 2. The pipe joint socket device 3 is a pipe joint socket ring 5 . The shield assembly device 4 is composed of an oil cylinder jacking mechanism 10, an assembling mechanism 6 and a shield tail sealing mechanism 7. The above three mechanisms are installed in a housing 8, and the jacking cylinder 9 of the oil cylinder jacking mechanism 10 is located at the bottom of the housing 8. At the front, the assembly mechanism 6 is located in the middle of the housing 8, and the shield tail grouting sealing mechanism 7 is located at the rear of the housing 8. The front end of the housing 8 is connected to the connecting end 2 at the rear end of the tunnel boring machine head 1. The housing The rear end of the 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com