Improved motor for pneumatic tools

A technology of pneumatic tools and motors, applied in the field of improved pneumatic tool motor devices, can solve problems affecting the performance and power of air motors, destroying bearing lubricating oil film, high-pressure air loss, etc., to achieve increased power, reduced loss, and utilization of air pressure Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

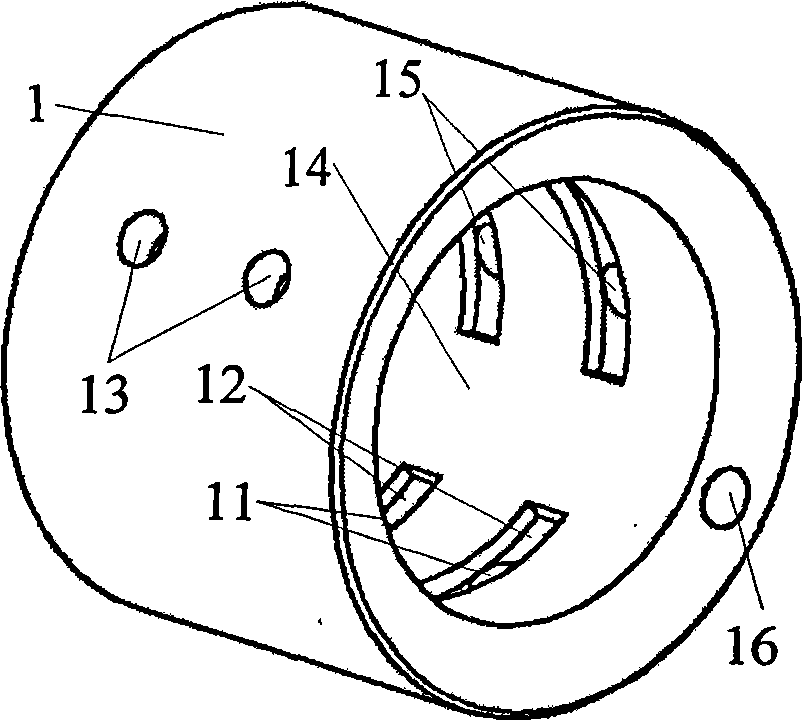

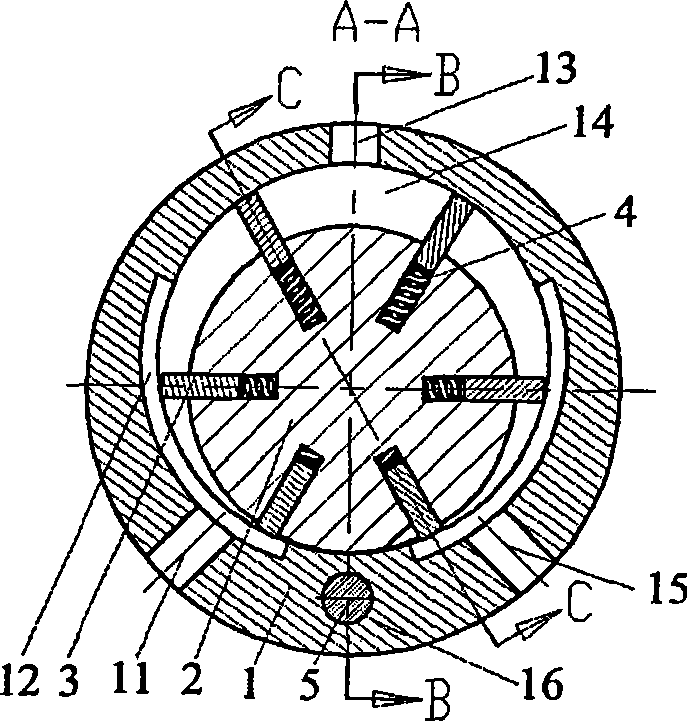

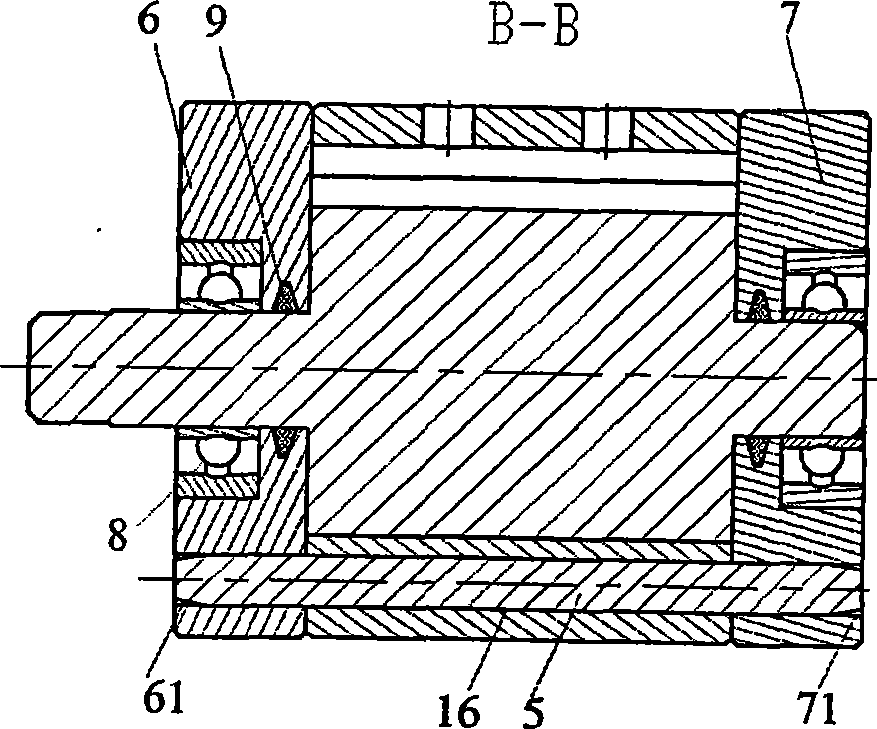

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] refer to figure 1 ~As shown in Fig. 5, the present invention includes a cylinder 1 and a rotor 2 having two main exhaust holes 13, and the rotor 2 is housed in the cylinder cavity 14 of an eccentric circular hole, and the rotor 2 is radially and equally divided into six grooves , each groove is equipped with blades 3, the two ends of the cylinder are sealed by the front cylinder cover 6 and the rear cylinder cover 7, and the cylinder cover is provided with bearings 8 to support the rotation of the rotor 2. The bottom of each blade 3 is provided with two cylindrical small bosses 31 on the end surface close to the bottom of the slot, and two small blind holes 21 are provided on the bottom surface of the rotor slot. One end of the spring 4 is inserted into the small blind holes 21, and the other end is covered Live small boss 31, have two air holes 11,15 symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com