A kind of forward osmosis membrane based on interface hydrophilic modification and preparation method thereof

A forward osmosis membrane, hydrophilic modification technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., to achieve the effect of reducing tortuosity, reducing osmotic resistance, and reducing brine ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0053] (1) Soak the polypropylene (PP) non-woven support material (basis weight 52 g / m2, thickness 85 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

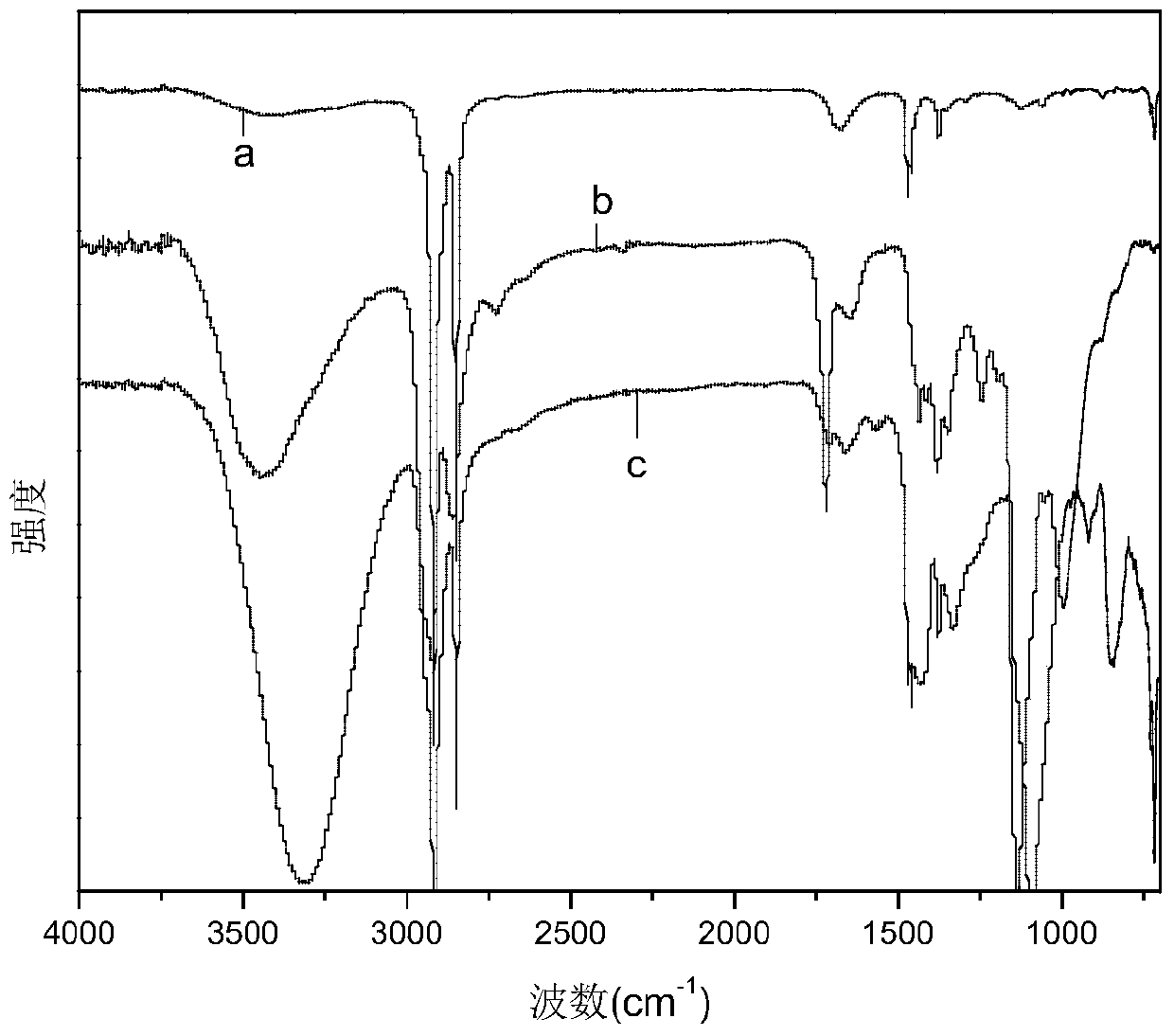

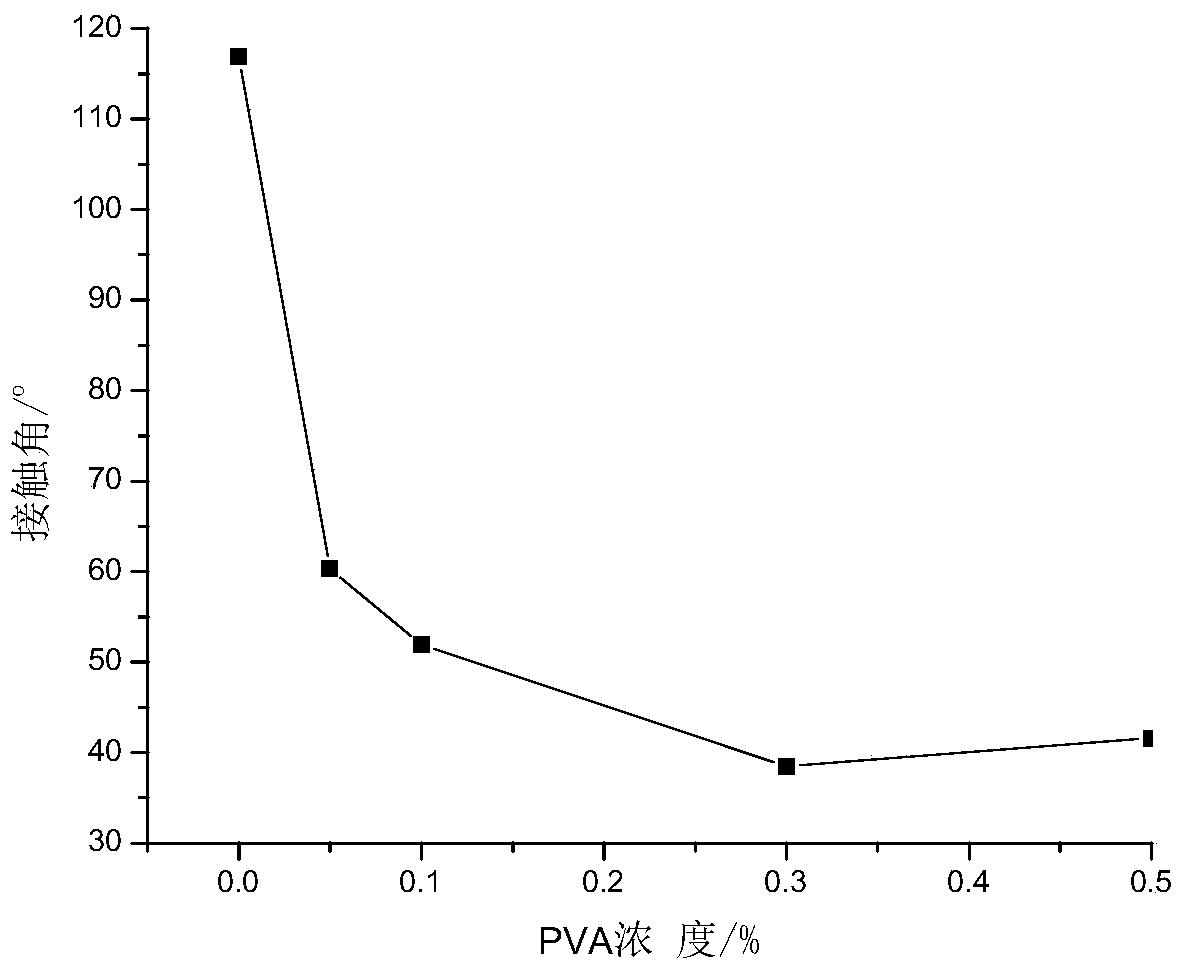

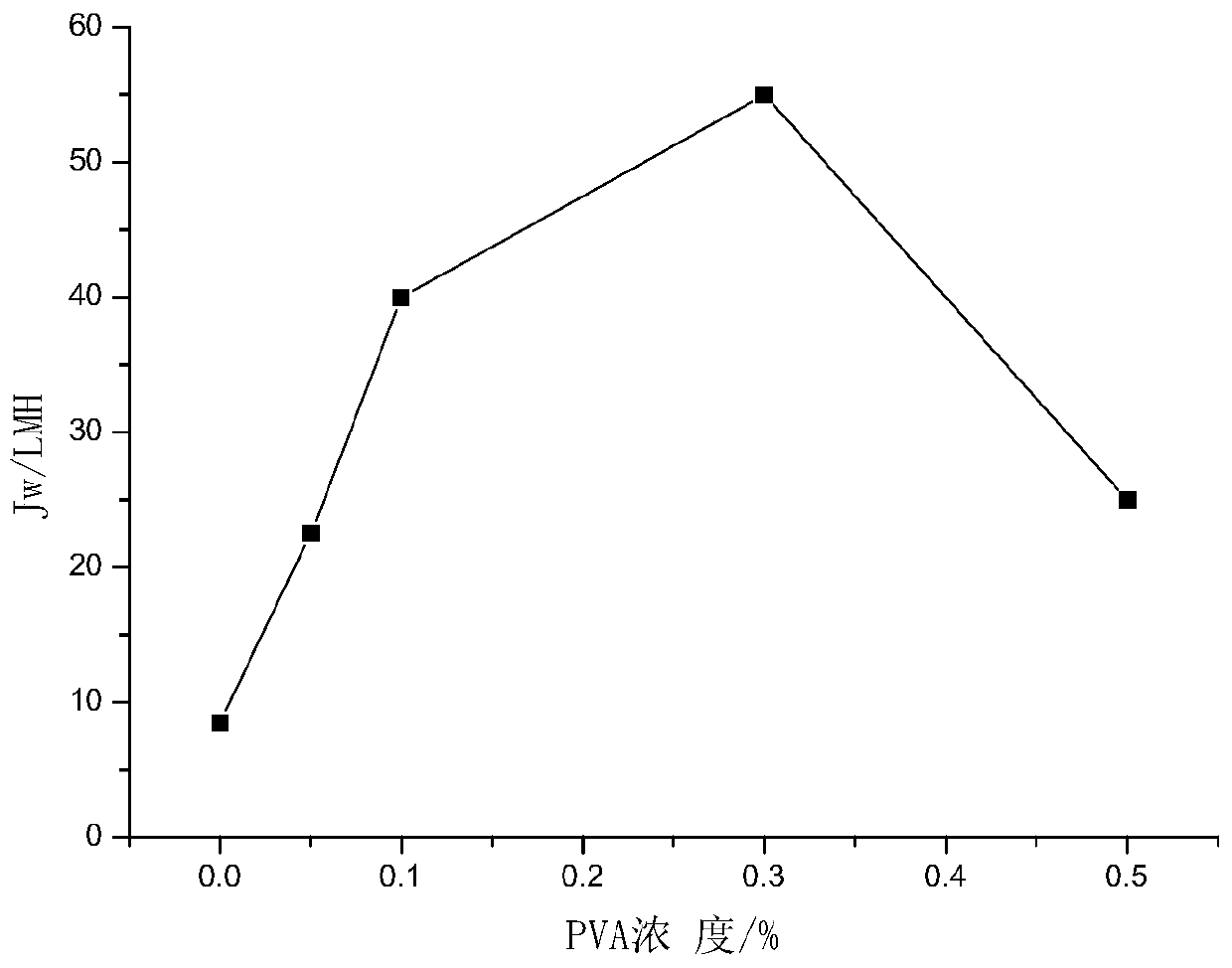

[0054] (2) Immerse the treated non-woven support material in an aqueous solution of hydrophilic polymer polyvinyl alcohol (PVA) with a mass percent concentration of 0.05%, 0.1%, 0.3%, and 0.5%, respectively, and then remove the excess solution, Dry and reserve;

[0055] (3) Add 13.1% (V%) cellulose triacetate (CTA) to 52.4% (V%) 1,4-dioxane, 19.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0056] (4) Pour the above-mentioned casting solution on the dried support material, scrape the film with a scraper with a gap of 150 microns, volatilize in the air for 30 seconds at room temperature and 90% relative humidity, and then immerse it in deionized w...

Embodiment 5

[0060] (1) Soak the polyester (PET) non-woven support material (basis weight 55 g / m2, thickness 66 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

[0061] (2) Immerse the treated non-woven support material in an aqueous solution of hydrophilic polymer polyvinyl alcohol (PVA) with a concentration of 0.3% by mass, then remove the excess solution, and dry it for later use;

[0062] (3) Add 10.1% (V%) cellulose triacetate (CTA) to 54.4% (V%) 1,4-dioxane, 20.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0063] (4) Pour the above-mentioned casting solution on the dried support material, scrape the film with a scraper with a gap of 160 microns, volatilize in the air for 30 seconds at room temperature and 80% relative humidity, and then immerse it in deionized water to make it dry. Gel to obtain nasce...

Embodiment 6

[0067] (1) Soak the polyester (PET) non-woven support material (basis weight 55 g / m2, thickness 66 microns) with acetone to remove impurities adsorbed on the surface, and then dry it for later use;

[0068] (2) Immerse the treated non-woven support material in a mixed solution of hydrophilic polymer polyvinyl alcohol (PVA) and cross-linking agent with a concentration of 0.3% by mass, react at 50°C for 1 hour, and then remove The excess solution was dried for later use; the crosslinking solution contained 10 vol.% sulfuric acid, 10 vol.% acetic acid, 10 vol.% methanol, and 2wt.% glutaraldehyde (GA) at a volume ratio of 1:2:3;

[0069] (3) Add 10.1% (V%) cellulose triacetate (CTA) to 54.4% (V%) 1,4-dioxane, 20.7% (V%) acetone, 8.2% (V%) methanol In a mixed solvent of 6.6% (V%) lactic acid, heat and stir at 40°C to dissolve, and let it stand for more than 24 hours to completely defoam;

[0070] (4) Pour the above-mentioned casting solution on the dried support material, scrape t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com