Preparation method of polyolefin microporous membrane and polyolefin microporous membrane

A polyolefin microporous membrane and polyolefin technology, applied in electrical components, electrochemical generators, circuits, etc., can solve problems such as reduced energy density, poor interface compatibility, and increased internal resistance of batteries to improve ion transmission capabilities and energy density, the overall thickness consistency is good, and the effect of reducing tortuosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

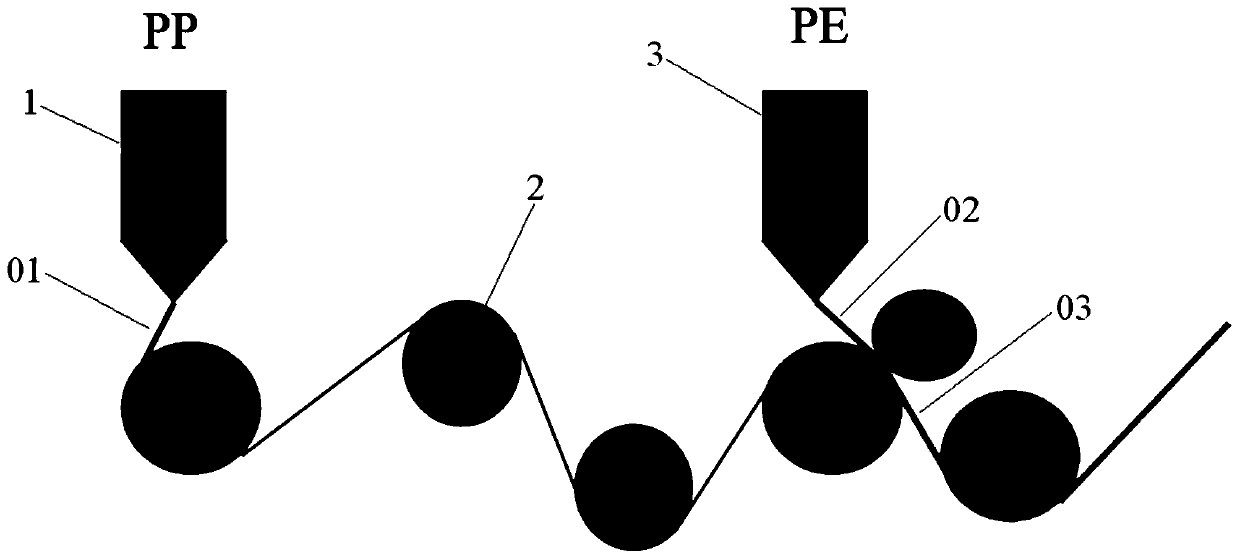

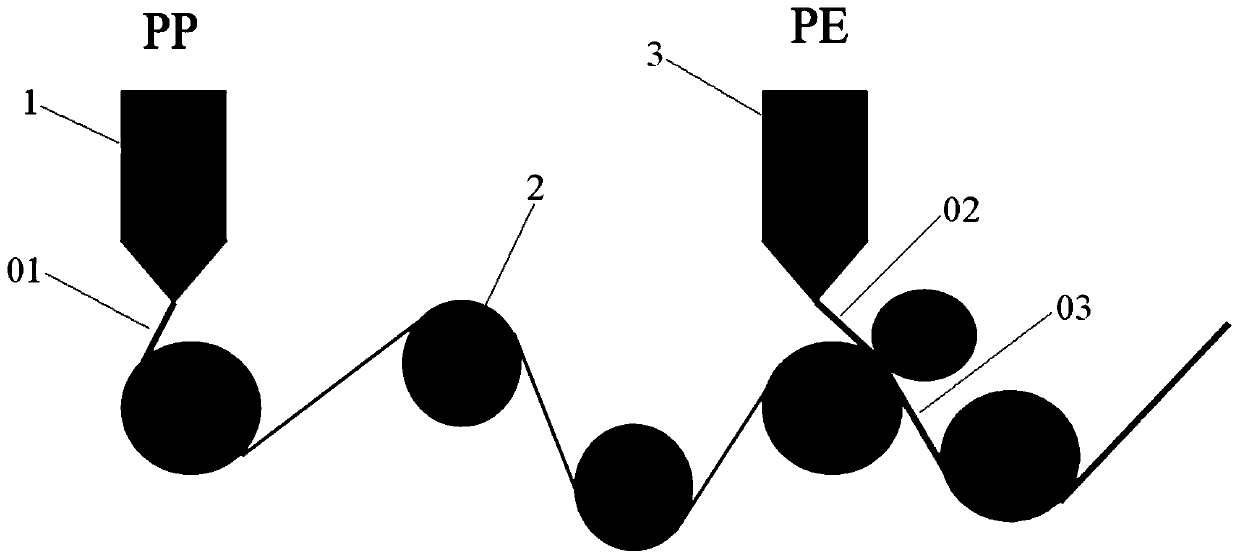

[0020] The preparation method of the present application breaks the limitation of the traditional PP / PE / PP three-layer diaphragm, and creatively uses the progressive tape casting process to prepare a double-layer composite polyolefin microporous membrane, so that the prepared double-layer composite polyolefin microporous membrane The membrane, while improving the interfacial contact, reduces the tortuosity of the double-layer composite polyolefin microporous membrane, making the resistance in the lithium ion transmission process smaller and the transmission rate faster.

[0021] The preparation method of the present application utilizes the difference in thermal stability of polyolefins of different materials, and takes into account the skeleton layer and protective layer of the prepared double-layer composite polyolefin microporous membrane through a new method of in-line casting and lamination. While improving the safety of the double-layer composite polyolefin microporous me...

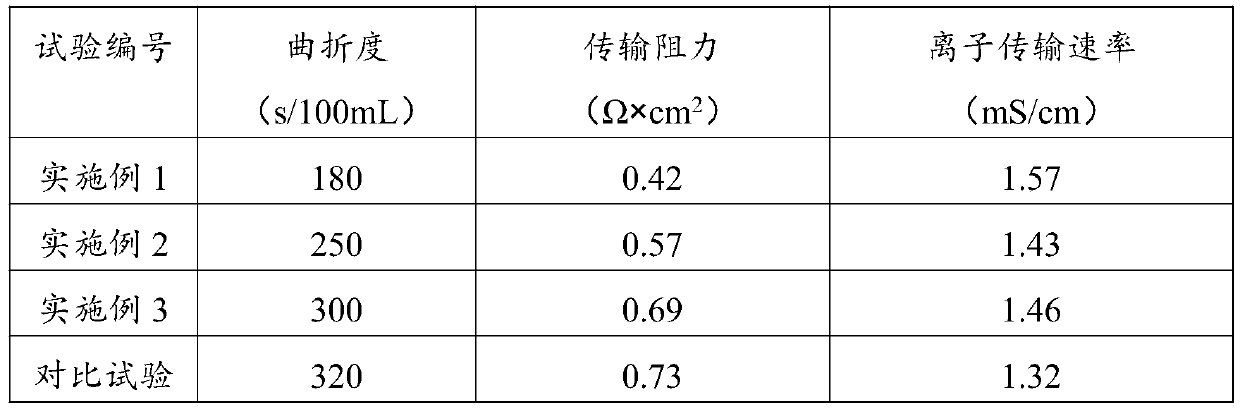

Embodiment 1

[0024] In this example, the melt index is 0.8g / 10min (230°C, 2.16kg), and the density is 0.9g / cm 3 Polypropylene is used as the first component polyolefin; the melt index is 0.72g / 10min (190°C, 2.16kg), and the density is 0.96g / cm 3 The polyethylene used as the second component polyolefin; two extruders were used to extrude the first component polyolefin and the second component polyolefin respectively, and the polypropylene and Polyolefin microporous membrane with polyethylene double layer composite.

[0025] In this example, the step-by-step tape casting process is as follows: figure 1 As shown, the first component polyolefin polypropylene is extruded by the first extruder 1 to form a polypropylene casting film 01, and then conveyed to the bottom of the second extruder 3 by the transfer roller 2, the second extruder 3 Extrude the second component polyolefin polyethylene 02 on the surface of the polypropylene cast film 01 to form a cast film 03 laminated with a polypropylen...

Embodiment 2

[0036] This example uses the same method as in Example 1 to prepare a double-layer composite polyolefin microporous membrane. The difference is that the first component polyolefin in this example is poly-1-butene, and the second component polyolefin is polyolefin. 1 identical polyethylene, all the other steps are identical with embodiment 1. The thickness of the double-layer composite polyolefin microporous membrane in this example is 20 μm, wherein the thickness of the poly-1-butene layer is 10 μm, and the thickness of the polyethylene layer is 10 μm.

[0037] Similarly, the same test method as in Example 1 was used to perform thickness uniformity sequencing, tortuosity test, diaphragm lithium ion transmission resistance test and lithium ion transmission rate test on the double-layer composite polyolefin microporous membrane of this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com